TOYOTA SYSTEM OF ACTIVE STABILITY

WHY TOYOTA FORKLIFTS ARE #1 IN SAFETY

No other manufacturer puts concern for the operator front and center like Toyota does. The proof is in their #1 ranking in safety year after year, through independent studies conducted by Peerless Media Research Group. As well as the fact that they meet or exceed both American National Standards Institute (ANSI) and Occupational Safety and Health Administration (OSHA) standards.

Watch the video below to see Toyota’s commitment to safety through their System of Active Stability.

SAS ADVANTAGE

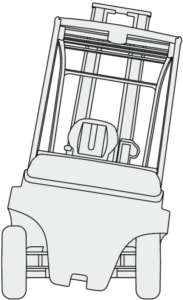

When it senses instability, SAS instantly engages the swing lock cylinder to stabilize the rear axle, creating the lateral stability needed to help reduce risk of tip-over.

WITHOUT SAS

WITH SAS

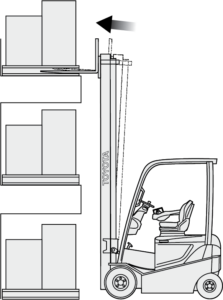

Automatic Fork Leveling

SAS automatic fork leveling control adjusts the mast so that the forks are level with the ground for ease in retrieving pallets at high levels

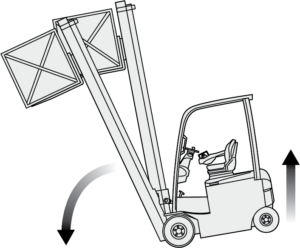

ACTIVE MAST FUNCTION CONTROLLER

Sensing the load weight and mast height, the rear tilt speed control governs the mast’s reverse tilt speed to decrease the chance of spilling unsecured loads or tipping the forklift backward.

WITHOUT SAS

WITH SAS

Forward tilt angle control automatically overrides the operator’s manual control, limiting the forward tilt of the mast and making it more difficult to spill a load. Or worse, tip the forklift forward.

WITHOUT SAS

WITH SAS

DOWNLOAD THE TOYOTA SYSTEM OF ACTIVE STABILITY BROCHURE

Read up on Toyota’s mission to provide stability in an unstable world.

READ NOW