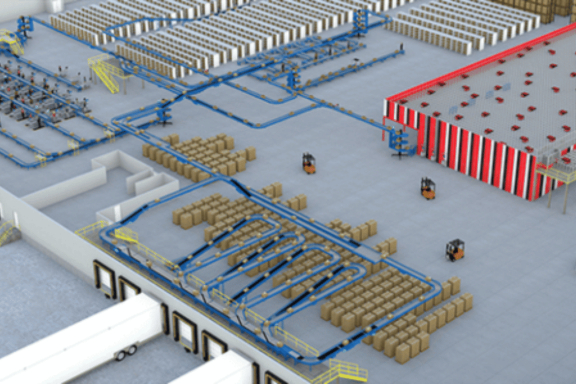

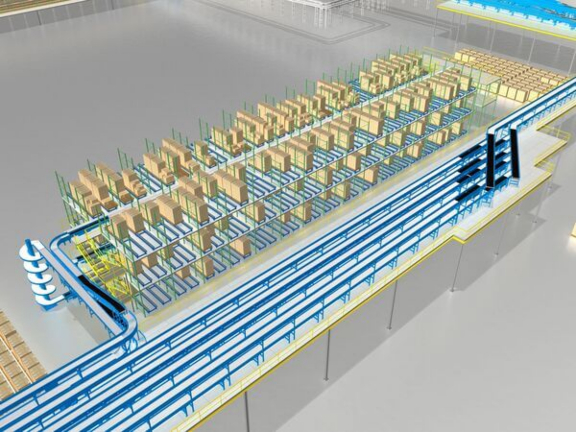

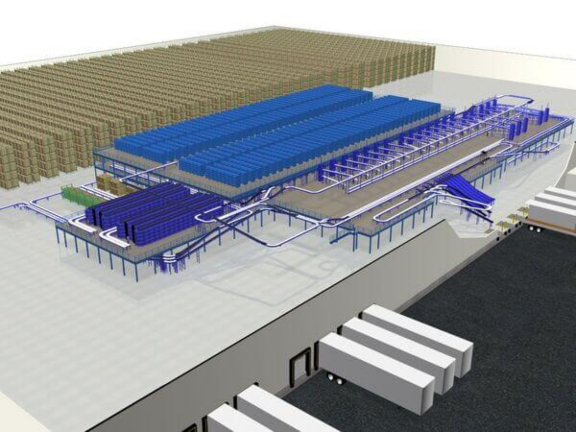

Improve Efficiency, Reduce Labor, and Gain a Competitive Edge with Our Conveyor System Design Services

Whether you need a complete system solution for new construction or are renovating an existing facility, we can design, commission, and install a conveyor system that works for you.

Our systems expert will work with you every step of the way, using extensive data gathering and analysis, expert planning, and focused execution within a proven strategy. We’ll consider your operational requirements as a whole, collect data, incorporate your feedback, and design a system that improves your efficiency, reduces your reliance on costly labor, and helps you gain an advantage over your competitors.

Do you have unique requirements?

We work across a broad spectrum of industry segments and use a brand-agnostic approach that allows us to select the best equipment and informational systems that work for your operation – regardless of manufacturer. So whatever the unique demands of your operation are, we can specify and select the best ancillary conveyor equipment. And if there isn’t a piece of standard equipment available to meet your application, we will create a custom design and have it manufactured.