Running a warehouse or industrial operation requires flexibility—and the right equipment can make all the difference. Purchasing a forklift outright isn’t always the most practical option, especially if you need short-term support, seasonal capacity, or a budget-friendly way to scale. In these situations, propane forklift rentals offer a smart, reliable solution.

Propane forklifts combine the strength and endurance of internal combustion engines with the versatility to work both indoors and outdoors. For many businesses, they strike the perfect balance between performance, uptime, and affordability. But before you decide if a propane forklift rental is the right move, it’s important to understand the advantages, limitations, and scenarios where they shine.

In this guide, we’ll break down everything you need to know: features, benefits, safety, attachments, and how propane compares to electric and diesel models. With this information, you’ll be able to make the best choice for your operation.

Let’s dive In!

Why Choose Propane Forklifts for Your Warehouse?

Efficiency and Power

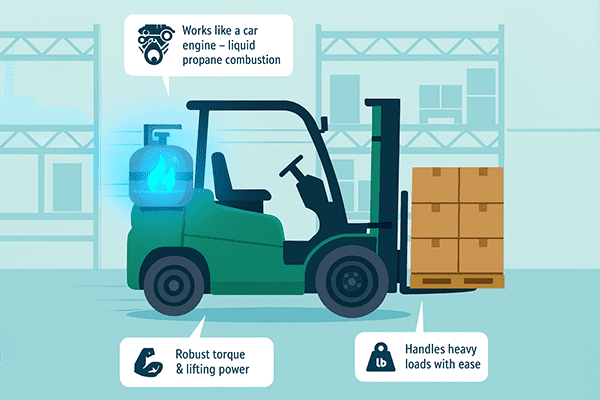

Propane forklifts are popular in warehouses because of their efficiency and power. A propane engine operates similarly to a car engine – it combusts liquid propane from a tank to drive the forklift. This means a propane-powered forklift provides robust torque and lifting capability. In practical terms, it can handle heavy pallets and loads with ease, maintaining full power throughout the job.

Versatility

Another big benefit is versatility. Propane forklifts have the flexibility to work both indoors and outdoors. Unlike diesel forklifts (which produce heavier emissions) or electric forklifts (which are generally limited to indoor use), propane units strike a middle ground. They run cleaner than diesel, so with proper ventilation they can be used inside a warehouse without significant air quality issues. At the same time, they have an internal combustion engine and often come with rugged tires, allowing them to operate outside on loading docks or in yard areas. This indoor/outdoor capability is invaluable for warehouses that need a single forklift to cover all bases.

Refuel Time

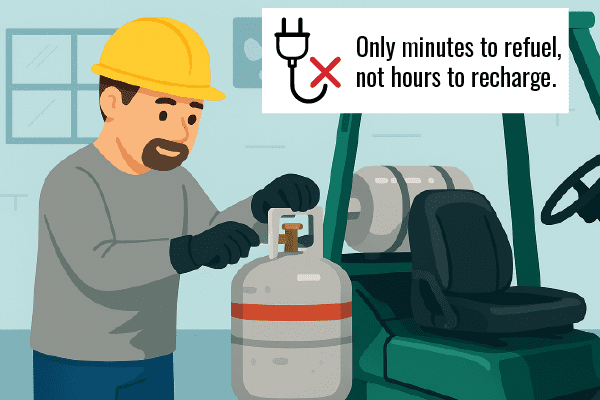

Speed and uptime are further reasons to choose propane. Refueling a propane forklift is fast – swapping an empty propane cylinder for a full one takes just minutes. There’s no lengthy charging downtime as with electric forklifts. If you have a spare tank on hand, you can keep the forklift running continuously across multiple shifts. In short, propane forklifts offer a powerful engine, multi-environment use, and minimal downtime – a combination that makes them an excellent choice for many warehouse and industrial scenarios.

Key Features of Propane Forklifts

When selecting a propane forklift rental, you’ll want to match the machine’s features to your job requirements. Here are some key factors to consider to ensure you rent the right forklift:

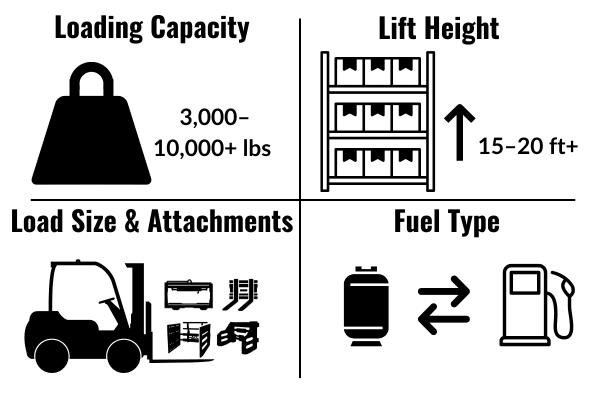

Lifting Capacity

Determine the weight of the loads you need to handle. Forklifts come in various rated capacities (e.g. 3,000 lbs, 5,000 lbs, 10,000 lbs, etc.). It’s crucial to choose a forklift with enough capacity to safely lift your heaviest loads. A good rule of thumb is to always err on the side of a higher capacity if you’re unsure, to maintain safety and avoid overloading the equipment.

Lift Height

Consider how high you need to lift materials. Propane forklifts are commonly available with two-stage or three-stage masts that can lift to heights of 15–20 feet (and sometimes more with special mast configurations). Measure the top shelf or rack height in your facility and choose a forklift with a mast that can reach a bit beyond that.

Load Size & Attachments

Think about the size and type of loads. Are you moving standard pallets, or odd-shaped items like appliances, rolls, or crates? The packaging of your items matters. Standard forks work for pallets, but if you have non-palletized loads (for example, large cartons or drywall sheets), you might need an attachment like a carton clamp or a slip-sheet handler.

Power and Fuel Options

Propane forklifts are known for high engine torque, which gives them strong acceleration and the ability to push/pull heavy loads. Some models are dual-fuel, meaning they can run on propane or gasoline, offering flexibility if you have access to both fuel types.

By evaluating these features you can select a propane forklift rental that perfectly matches your operational needs. Essentially, you want a forklift that can safely lift your loads to the required height and handle your work environment with ease.

Renting a Propane Forklift

Renting a propane forklift can differ from one provider to another, but with Conger, the process is simple and hassle-free. Follow this step-by-step guide to get the equipment you need and put it to work for your operation:

1. Contact Our Rental Team

Start by reaching out via phone or our online request form. Let us know what you need, including:

- Required lift capacity

- Fuel type (LP or electric)

- Maximum lift height and any restrictions on lowered height

- Fork size

- Operating indoors, outdoors or both

- Duration of the rental – daily, weekly, or monthly

This information helps us recommend the most suitable forklift for your application.

Please note: Conger does not offer rentals for personal use. Rentals are available to businesses only and require proof of insurance in the form of a certificate of insurance.

2. Receive a Customized Quote

We’ll send a tailored quote based on your needs. It will include:

- Recommended forklift model(s)

- Rental rates based on duration

- Any requested attachments or extras (e.g., propane tanks, side shifters)

Review the quote to confirm it meets your requirements. If adjustments are needed, we will gladly make the changes.

3. Approval and Delivery

Once you are ready to proceed, please approve the rental agreement by signing the contract and providing the necessary payment information—such as a purchase order for charge accounts or a credit card. A credit card is required for all COD customers. We will coordinate delivery to your site at a mutually convenient time. Depending on the type of equipment, ground loading may be available. Alternatively, you are welcome to handle pickup and return on your own.

Propane Forklift Attachments

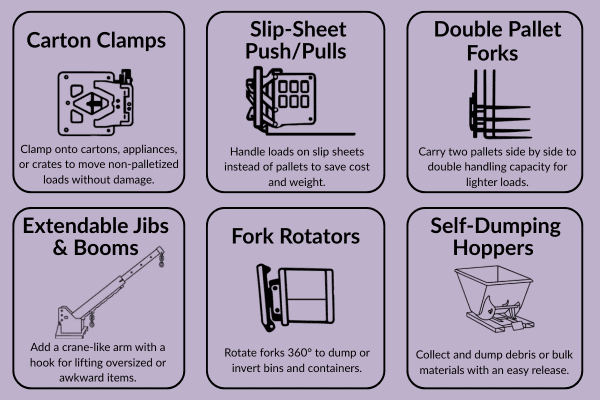

One way to get even more out of your propane forklift rental is by using forklift attachments. The purpose of forklift attachment rentals is to allow you to handle different types of loads safely and effectively without needing a completely different machine. Common attachments available for propane forklifts include:

Carton Clamps: These attachments have wide, flat pads that clamp onto the sides of cartons, appliances, or crates. They let you lift and move loads that aren’t on pallets (like whitegoods or electronics boxes) without crushing them. This is useful in industries like appliance warehouses where not everything is palletized.

Slip-Sheet Push/Pulls: A push/pull attachment allows a forklift to grab onto slip sheets (thin cardboard or plastic sheets under a load) and pull a load onto a flat platen, then push it off at delivery. This is often used in food and beverage warehouses to handle loads on slip sheets instead of pallets, saving the cost and weight of pallets.

Double Pallet Forks (Single-Double Attachment): This is an attachment that can spread apart to carry two pallets side by side, effectively doubling the forklift’s pallet handling capacity for light or moderate loads. It’s great for high-volume loading where each pallet isn’t too heavy – you can move two at once and increase throughput.

Fork Rotators: A fork rotation attachment allows the forks (and the load) to rotate, typically 360 degrees. This is extremely useful for dumping bins or transferring materials. For instance, in agriculture or recycling, you might use a rotator to pick up a bin of produce or scrap and then tilt it to dump the contents out into a container.

Extendable Jibs & Booms: An extendable jib is like a crane arm that attaches to your forklift’s carriage. It provides a hook and an extended reach to lift objects that are not convenient to palletize – such as pipes, machinery, or oversized equipment – essentially turning your forklift into a small mobile crane for certain tasks.

Self-Dumping Hoppers and Box Attachments: These are hopper or box units that can be attached to forks, allowing you to collect waste or bulk materials. A self-dump hopper, for example, can be filled with debris and then easily dumped by the forklift operator pulling a release lever. Steel trash box attachments similarly let a propane forklift serve as a mobile trash bin that can be lifted and emptied as needed, improving on-site cleanliness and efficiency.

Using the right attachment not only boosts the functionality of your propane forklift but also enhances operational efficiency. You can reduce the need for manual labor or additional equipment. For instance, instead of using a separate crane to lift a long pipe, an extendable jib on your forklift can do it. Or instead of workers loading loose trash into dumpsters by hand, a forklift with a hopper can haul and dump it quickly. Attachments also contribute to safety by ensuring loads are handled in a secure manner designed for that specific load type. Always make sure that any attachment you use is compatible with the forklift and that the operator is trained in its use, as attachments can affect the forklift’s capacity and balance.

Safety Tips for Operating Propane Forklifts

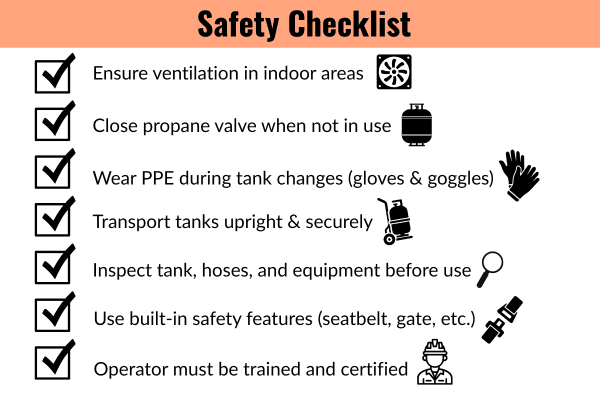

Safety is paramount when operating any forklift, including propane units. Propane forklifts have some unique considerations (like handling fuel cylinders) in addition to general forklift safety rules. Here are essential safety tips to keep your operators and workplace safe:

Proper Ventilation Indoors: Always ensure there is adequate ventilation when using a propane forklift indoors. Propane is a clean-burning fuel relative to gasoline or diesel, but it does produce exhaust gases – mainly carbon monoxide (CO) and nitrogen oxides. Without ventilation, these can build up to dangerous levels. Never operate a propane forklift in a small, enclosed space with poor ventilation. (OSHA guidelines warn against using any combustion engine in confined areas where vapors can accumulate.) Remember that carbon monoxide is colorless and odorless – you won’t know it’s there until detectors go off or symptoms occur. Good airflow or exhaust extraction is a must for indoor applications.

Close the Valve When Not in Use: Propane forklifts use an onboard cylinder tank of liquid propane. Whenever the forklift is not in active use (for example, parked overnight or being serviced), make sure to close the tank’s supply valve. This prevents propane from possibly leaking out if a hose or seal were to fail. It’s a simple step that greatly reduces fire or leak risks when the machine is idle.

Safe Refueling and Tank Changes: Only trained personnel should replace or refill propane cylinders. When changing a propane tank, wear proper personal protective equipment – thick gloves to protect against freezing liquid propane, and safety glasses. Shut off the forklift and close the empty tank’s valve before disconnecting it. After connecting a full tank, open the valve slowly and check for leaks. A common practice is to listen and smell for any leaking gas (propane has a distinct odor added to help detect leaks). Never check for leaks with an open flame. If you suspect a leak – if you hear hissing or see frost accumulating around a connection – turn off the valve and address the issue before restarting the forklift. Also, ensure any leftover pressure in the hose is bled off according to manufacturer instructions when swapping tanks, so you don’t get a spray of propane when disconnecting.

Transport and Store Propane Cylinders Safely: If you have spare propane tanks, handle them with care. Always transport cylinders upright and secured – for example, use a tank cradle or strap them in an upright position in a vehicle. Do not transport propane cylinders in an enclosed car trunk or where they can roll around. Generally, no more than four cylinders should be transported in a normal vehicle at one time (this limit can vary by locale, but the idea is to minimize risk). For storage, keep propane cylinders in a well-ventilated area, outdoors if possible, and away from any ignition sources or excessive heat. They should be stored upright on a stable surface. Proper storage reduces the risk of fire and helps keep the propane fuel in good condition.

Inspect Equipment Regularly: Before each shift, the operator should do a quick pre-operation inspection of the forklift. For propane lifts, this includes checking the propane tank and hose for any signs of damage or leaks (frost, cracks, strong odor of gas), ensuring the tank is mounted securely, and verifying that the pressure relief valve on the tank is pointed away from the operator. Also inspect the forklift’s tires, brakes, lights, and warning devices. If anything looks out of order, address it before use. Propane tanks themselves should be periodically inspected for rust, dents, or expiration dates (propane tanks must be re-certified every so many years). A damaged cylinder should not be used.

Built-in Safety Features: Modern propane forklifts come with safety features like automatic shut-off valves and fuel system protections. For example, if the fuel line were to break, an excess flow valve in the tank may stop the propane flow to prevent a large leak. Be familiar with your equipment’s safety features and never disable or bypass them. Additionally, always use the seatbelt (on sit-down forklifts) and keep arms/legs inside the operator area. For stand-up forklifts, there is usually a rear gate or strap – ensure it’s used to prevent falls or ejections in case of a tip. While these are not unique to propane models, they are general forklift safety practices that are just as crucial.

Operator Training: Only trained and certified operators should drive a forklift. This is an OSHA requirement and for good reason – forklifts can be dangerous if misused. Make sure anyone operating the propane forklift understands how to handle the vehicle’s controls smoothly, how to work with the propane fuel system, and what to do in an emergency (such as if they smell a propane leak or if an alarm goes off). Training should also cover load handling (like not exceeding capacity, keeping loads low when traveling, etc.) to prevent tip-overs.

By following these safety tips and ensuring awareness of propane-specific precautions, you can maintain a safe working environment while enjoying the benefits of your propane forklift rental. Remember that while propane forklifts have many advantages, they do introduce a fuel source that must be handled with respect. With proper procedures, propane forklifts are very safe – they are used in thousands of warehouses daily without incident. It all comes down to following guidelines and using common sense every time the forklift is in operation.

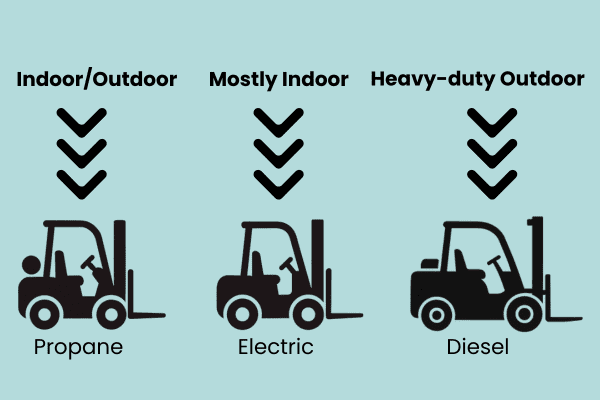

Comparing Propane Forklifts to Electric and Diesel Options

How do propane forklifts stack up against their electric and diesel counterparts? If you’re unsure whether to choose propane, electric, or diesel, consider the following comparisons on key factors:

- Emissions & Indoor Use: Electric forklifts produce zero emissions, ideal for indoor air quality. Propane forklifts emit some carbon monoxide but significantly less than diesel, making them suitable indoors with proper ventilation. Diesel forklifts emit the most pollutants and usually aren’t suitable indoors.

- Outdoor Performance: Propane forklifts are reliable outdoors, handling weather and moderate rough terrain better than electric models, which can struggle in wet or cold conditions. Diesel forklifts excel in heavy-duty outdoor tasks but propane is effective for mixed indoor/outdoor use.

- Power & Performance: Propane forklifts offer consistent power and torque, maintaining performance throughout their fuel cycle. Electric forklifts provide precise control but can lose power as batteries drain. Diesel forklifts offer the highest torque, beneficial for heavy loads, but propane closely matches them for typical warehouse tasks.

- Refueling vs. Recharging: Propane forklifts refuel quickly (tank swap in minutes), minimizing downtime compared to electric forklifts, which require hours to recharge. Diesel also refuels quickly but propane balances convenience with cleaner operation, especially in multi-shift scenarios.

- Fuel & Operating Costs: Electric forklifts have the lowest fuel cost (electricity), but battery replacements and charging infrastructure add expense. Propane has moderate fuel costs and maintenance, cheaper than diesel but higher than electric, often balanced by productivity advantages and flexibility.

- Upfront Cost & Lifespan: Propane forklifts typically cost less upfront than electric forklifts, though electrics generally have longer lifespans due to fewer moving parts. Diesel forklifts also have long lifespans but higher emissions and maintenance. In summary, propane forklifts offer a balanced mix of power, versatility, and moderate costs, making them a popular choice in warehouses.

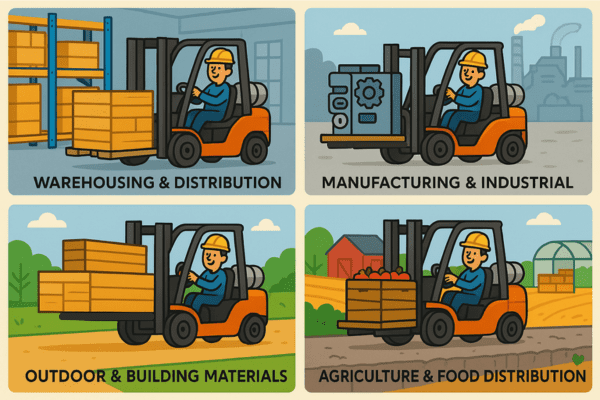

Industries That Benefit from Propane Forklift Rentals

Propane forklift rentals are utilized across a wide range of industries. Their versatility for indoor/outdoor work and strong performance makes them suitable for many applications. Here are a few types of operations that particularly benefit from using propane forklifts:

- Warehousing & Distribution: Warehouses and logistics centers frequently use propane forklifts for efficient indoor/outdoor operations, loading trucks, and high-volume inventory handling. Their quick tank swaps maximize uptime, especially useful in busy retail distribution environments.

- Manufacturing & Industrial: Manufacturing plants utilize propane forklifts for moving raw materials and finished products. Their power suits heavy lifting, while quick refueling supports continuous operations. Popular in automotive, metal fabrication, and machinery manufacturing, propane forklifts maintain high productivity with minimal downtime.

- Outdoor & Building Materials: Businesses with outdoor storage—like lumber yards, construction suppliers, and garden centers—prefer propane forklifts for their reliability on uneven terrain and strong lifting capacity. Unlike diesel, propane forklifts can safely transition indoors for loading or staging.

- Agriculture & Food Distribution: Agricultural operations and food distributors rely on propane forklifts for cleanliness and consistent performance. Ideal for seasonal demand, propane rentals help these businesses scale equipment use efficiently during peak periods, ensuring flexibility without contamination risks.

Of course, these are just a few examples. Virtually any business that needs a forklift but doesn’t want the commitment of owning one could benefit from a propane forklift rental if their use case matches the strengths of propane (indoor/outdoor flexibility, continuous power, etc.).

Conclusion

In summary, propane forklift rentals are the right choice for a wide array of businesses. If your operations require a dependable, powerful forklift that can work in different environments and you value quick refueling and lower upfront cost, a propane unit is likely a great fit. By considering the factors outlined in this guide – from equipment features and safety to comparing fuel types – you can determine if a propane forklift rental aligns with your needs.