This article is all about aerial lift safety tips for operators, managers, and pedestrians.

In it, you’ll learn:

- What an aerial lift is

- The most common aerial lifts hazards

- 15 aerial work platforms safety tips

Let’s get started!

What Is an Aerial Lift?

Today, many job sites prefer aerial lifts to ladders and scaffolding because of their flexibility and mobility.

But there’s some confusion about what exactly aerial lifts are.

And since aerial lifts are usually used in the workplace, it makes sense to go to OSHA for the definition.

So, what does OSHA consider an aerial lift?

OSHA gives the following definition:

“An aerial lift is any vehicle-mounted device, telescoping or articulating, used to elevate personnel, including:

- Extendable boom platforms

- Aerial ladders

- Articulating (jointed) boom platforms

- Vertical towers, and

- Any combination of the above.”

– OSHA Standard 1910.67(a)(2)

It’s important to note that this definition does not include scissor lifts.

Instead, those are considered scaffolding.

What Are Aerial Lifts Used For?

Aerial lifts help people and equipment reach levels of heights that they or other types of machines cannot reach.

They’re used in many industries including:

- Construction

- Building maintenance

- Safety inspections

- Electric or telephone line repair

What Are the Most Common Aerial Lift Hazards?

According to OSHA, the following hazards can lead to injury or death:

Electrocution

Electric shock can occur from contact with power lines, electrical wires, and conductors.

Electric shock can also transfer to you through the machine if it lacks insulation and touches a power line.

Falling Objects

Objects falling from the lift, such as tools or materials, can strike someone beneath the lift.

And this can cause serious injury or death.

Tip-Overs

Aerial lifts become less stable as their height increases.

Because of the increased instability, tip-overs can occur because of the slightest obstacles like debris, uneven terrain, holes, or inclines.

Falling from Height

Operators can be ejected from the platform while the aerial lift is operating.

Falls usually occur when an operator isn’t wearing a harness or fails to hook their harness to the platform properly.

Structural Failures

Structural failures can cause the aerial lift to collapse.

This can happen if the machine is defective or overloaded.

Entanglements

Aerial lifts have many moving parts like cords, chains, pulleys, and ropes.

And each of these can create pinch points and entanglements, resulting in serious injuries.

Collisions

Collisions occur most often when the aerial lift is operating in high-traffic areas.

Collision hazards can also happen when contact is made with overhead obstructions.

15 Aerial Lift Safety Tips

1. Know the Rules

OSHA and ANSI specify the safety regulations and standards for aerial lift usage and handling.

OSHA provides regulations, which are the legal rules and guidelines that employers, users, and operators need to abide by.

ANSI, on the other hand, formulates the industry standards for aerial lift design and usage.

In that sense, ANSI rules are voluntary – not legal requirements.

So does that mean you don’t have to follow them?

Not necessarily.

That’s because OSHA often incorporates ANSI’s rules into their own.

And that effectively makes the ANSI rules the law.

So, what are the OSHA boom lift safety requirements?

They are:

- 29 CFR 1926.453 – Aerial lifts.

- 29 CFR 1910.67 – Vehicle-mounted elevating and rotating work platforms.

- 29 CFR 1910.269(p) – Electric power generation, transmission, and distribution.

- 29 CFR 1926.21 – Safety training and education.

- 29 CFR 1926.502 – Fall protection systems criteria and practices.

Now, what are ANSI’s aerial lift rules?

They’re contained within the ANSI A92 standard.

2. Make Sure Your Employees Are Trained

Is aerial lift training OSHA-required?

Answer: Yes.

OSHA mandates that “Only trained and authorized persons are allowed to operate an aerial lift.”

So what should this training include?

-

Explanations of electrical, fall, and falling object hazards

-

Procedures for dealing with hazards

-

Recognizing and avoiding unsafe conditions in the work setting

-

How to correctly operate the lift (including maximum intended load and load capacity)

-

Demonstrations of the skills and knowledge needed to operate an aerial lift before using it on the job

-

When and how to perform inspections

-

Manufacturer’s requirements

Aerial lift safety training isn’t a “one and done” thing, either.

Instead, OSHA mandates retraining in several circumstances, including:

-

When operators are using a different aerial lift type than they’re trained on

-

An accident occurs

-

A new hazard is discovered

-

Operators are observed using an aerial lift improperly

Now, ANSI has additional training regulations in place that you should be aware of.

These regulations apply to owners, users, supervisors, maintenance personnel, passengers, and operators.

Some of the key training requirements of the A92 standard are:

-

All supervisors who oversee personnel operating aerial lifts need to have specific supervisor training

-

All operators’ previous aerial lift training is now null and void, and they need to be re-trained under the new standards

-

All platform occupants must have a basic level of knowledge to work safely on aerial lifts, including how to operate the controls in an emergency

For more information on ANSI’s aerial lift training standards, you can read this helpful guide from Genie.

3. Be Vigilant Around Power Lines

Working at height with aerial lifts can often mean working around power lines.

And getting an electric shock from a live power line is obviously a serious hazard.

So when working near a power line, aerial lift operators should:

-

Inspect the work area for cables and live power lines

-

Always treat overhead power lines as energized. Do this even if they appear insulated or down

-

Always wear the correct PPE when operating the lift near a power line

-

Maintain a minimum clearance of at least 10 feet away from the overhead line

-

Keep any conductive object that can contact the power line a minimum of 10 feet away from it

-

Shield any power cables

-

Only use insulated aerial lifts designed to work near power lines

-

Ensure that workers are adequately trained and have certified electrical training

4. Watch Out for Pedestrians

Pedestrians face several dangers when near aerial lifts.

These include:

- Being struck or run over

- Being crushed by a lowering platform

- Being struck by falling objects

So, keeping pedestrians safe around aerial lifts is crucial.

An effective way to do this is by implementing traffic control measures.

What should that entail?

OSHA’s guidelines on this include:

-

Placing an advanced warning sign

-

Setting up safety cones or barricades

-

Roping the area off

-

Using caution when lowering the platform

-

Guiding motorists through the traffic control zone

-

Installing screens between the toe boards and guardrails to protect pedestrians and workers underneath from falling objects

One of the most dangerous situations for pedestrians is when aerial lift operators cannot see around them.

So many folks wonder: Do you need a spotter for an aerial lift?

And the answer is that anytime there’s a hazard present, you should have a spotter.

After all, spotters can help guide the operator as well as keep pedestrians out of harm’s way.

5. Inspect Your Work Zone First

Work zones can have many risks that threaten the safe operation of aerial lifts.

And so OSHA requires that work zones be inspected for hazards.

Workers must then take corrective actions to eliminate all threats before and during aerial lift operations.

Some of these hazards to look out for include:

-

Potholes, drop-offs, holes, loose dirt, slope, ditches, bumps, and other unstable surfaces

-

Debris and other floor obstructions

-

Overhead obstructions like electric power lines and communication cables

-

Inadequate ceiling heights

-

High wind, ice, snow, and other severe weather conditions

-

Other aerial lifts within close proximity

6. Watch Your Overhead While Raising

You must pay attention to any overhead obstructions while raising the platform.

Otherwise, you can risk crushing yourself or the lift.

If you’re working indoors, the overhead hazards to watch for are:

- Ceilings

- Sprinklers

- Heating/cooling units

- Fans

- Pipes

- Lights

And when you’re working outside, watch out for:

- Electrical power lines

- Communication cables

- Cranes or other lifts within the work zone

7. Wear Fall Protection

Fall protection should be a key item in your aerial lift safety checklist.

Aerial lift operators and users should wear harnesses attached to the lifting platform.

These help in case the operator falls out of the platform or bucket.

But not just any aerial lift safety harness will do.

Rather, you should wear a body harness – not just a body belt.

Why?

Because a body belt only fits around the operator’s waist.

And if the operator falls, the body belt can cause severe injury to the spine or asphyxiation by compressing the lungs.

A body harness, on the other hand, fits around the operator’s legs, arms, and torso.

And in the event of a fall, the operator is at a lower risk of injury to their organs or skeletal system.

“…there are hazards associated with body belts that are greatly reduced by the substitution of body harnesses. Accordingly, we believe that body harnesses rather than body belts are the appropriate form of fall protection for employees working on elevated powered industrial truck platforms.”

Besides the body harness itself, you’ll need to ensure operators are attached with a lanyard.

And part of that includes making sure that the lanyard is the proper length.

The lanyard length must take into account the worker’s height and the lift’s platform height along with a three-foot safety margin.

So here’s the lanyard length formula:

- Take the platform height

- Subtract the height of the operator

- Subtract 3 feet

The result is the maximum lanyard length.

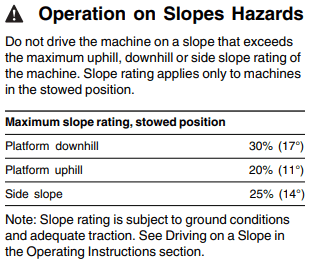

8. Be Aware of Slopes

Slopes can present a heightened risk of boom lift tip-overs.

So if possible, avoid using the lift on slopes.

But if you must, do so with extreme caution.

Here’s how:

First, check if your aerial lift is rated to work on an incline.

If it is, you’ll next need to find your lift’s allowed maximum slope or safe working angle.

Where can you find this?

It’s often specified on the manufacturer’s identification plate or marked by a decal on the platform.

If not, check the operator’s manual.

If your lift can handle the slope you’ve encountered, follow these safety tips for navigating slopes:

-

Only trained operators should move machines on a slope

-

Make sure to turn on the aerial lift’s slope sensor. An audible alarm will alert the operator if the lift reaches a slope

-

Use the right outriggers and position them properly for the slope

-

Install wheel chocks if the manufacturer allows

-

Limit the lift’s stowed driving speed according to the slope’s surface traction

-

Do not raise or extend the boom arm unless on a level, firm surface

9. Watch Out for Falling Objects

Aerial lift operators often have tools and materials in the basket.

But these can easily fall and cause injury or death, especially considering an elevated platform can be 45 feet or higher.

Of course, you can’t always tell when objects will fall.

But you can take measures to prevent it from happening, including:

-

Having OSHA-approved dropped object prevention training

-

Wear hard hats and steel-toe shoes if working around aerial lifts

-

Use debris nets. The right debris nets will help workers to easily collect items that fall from the lift and protect the workers and bystanders below the lifts

-

Use toe boards. This is a piece of wood or metal placed on an aerial lift to prevent objects and tools from falling off the lift

-

Ensure the aerial work surface has no loose objects that can fall. Secure any small tools or hardware to prevent falling objects

-

Organize your bucket/platform. Know where everything is to eliminate clumsy, awkward actions that could result in dropped objects

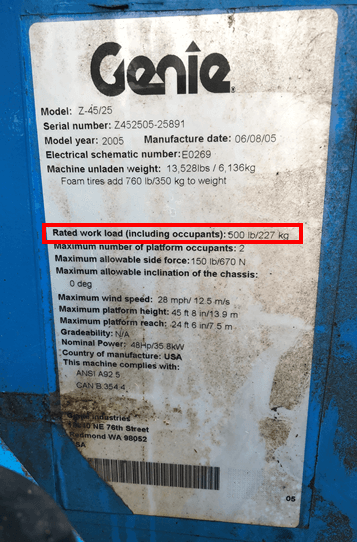

10. Check the Weight Limit

Weight limits for aerial lifts include the operator, tools, equipment, and supplies on the platform.

It’s important to know how much weight an aerial lift can hold to support your work.

“You should always be aware of the limits and be sure never to exceed the lift’s manufacturer-provided maximum operating weight capacity.”

OSHA Standard 1926.453(b)(2)(vi)

Otherwise, you can risk collapsing the lift and causing serious injury.

So, how much weight can a boom lift lift?

Different aerial lifts types have different platform weight limits.

For example, the weight limit of boom lifts ranges from 350 lbs. to 1,000 lbs., with 500 lbs. being the most common.

Vertical man lifts, on the other hand, are generally rated for up to 350 lbs.

If you’re not sure of the weight limit of your aerial lift, here’s how to check:

- Check the owner’s manual

- Check the lift’s data plate

- Check if a decal marks it on the platform

11. Never Use an Aerial Lift as a Crane

A common question folks have is: Can you use an aerial lift as a crane?

As you can tell from this section’s heading (and if you read tip #10), the answer is “No.”

Aerial lifts are designed for elevating personnel, tools, and some materials.

But they’re not designed to lift heavy loads.

Using an aerial lift as a crane can cause the mechanical components to fail, leading to injury and possible death.

So if you need to lift heavy materials, use a forklift, telehandler, or crane instead.

12. Inspect Before Operating

How often do aerial lifts need to be inspected?

Answer: OSHA requires a pre-start inspection before every work shift.

This is to verify that the aerial lift and all its components are safe and in good operating condition.

So what’s involved in aerial lift inspections?

Step #1: Start with the vehicle itself

This includes:

-

Checking fluid levels (oil, hydraulic, fuel, and coolant)

-

Verifying that there are no leaks

-

Checking the battery level and charger

-

Inspecting the wheels and tires

-

Testing the lower-level controls

-

Testing the steering and brakes

-

Checking the horn, lights, gauges, and backup alarms

Step #2: Verify the lift’s components

This includes the:

-

Operating and emergency controls

-

Hydraulic, electrical, fuel, and pneumatic systems

-

Guardrail systems, cable, and wiring harnesses

-

Personal protective devices

-

Insulating components, including fiberglass

-

Verifying loose or missing parts

-

Replacing unreadable or missing placards or warnings, including operational, control, and instructional markings

-

Checking locking pins and mechanical fasteners

-

Inspecting outriggers, stabilizers, and wheel chocks

Make sure you perform these inspections and tests before loading any workers or supplies.

13. Keep Up on Maintenance

Aerial lifts are like any other vehicle or piece of equipment – they need regular maintenance.

Maintenance helps keep the lift safe and in proper operating condition, improving its productivity.

It also saves money on repairs and extends the equipment’s life.

So, how often should you perform maintenance on your aerial lift?

ANSI standards (ANSI/SIA 92.6-1999) recommend both frequent and annual aerial lift maintenance performed by a qualified mechanic or technician.

Frequent inspections should occur every three months or 150 hours (whichever comes first) or if the lift hasn’t been in use for more than three months.

Annual inspections must occur within 13 months of the most recent annual inspection.

To learn more about aerial lift maintenance, you can read our guide.

14. Check the Wind Speed

Aerial lifts are susceptible to wind since they operate at elevated heights.

And too much wind can tip over the aerial lift.

So, you need to know the wind speed limit for the area you’re operating in to avoid exceeding the lift’s rating.

When is it too windy to use a boom lift?

The general rule of thumb is that the max wind speed for a boom lift is 28 mph.

But for exact specifications, you should refer to your owner’s manual.

15. Never Disable Safety Features

Safety features help to minimize the risk of hazards, incidents, or near-miss events.

Some safety features include:

- Guardrails

- Travel alarms

- Warning lights

- Emergency stop

- Tilt alarm

- Limit switch

- Porthole protection sensors

So, operators must not alter, modify, or disable any aerial lift’s safety devices without the manufacturer’s authorization.

Disregarding this will put the operator and pedestrians at risk.

Conclusion

That’s it: 15 aerial lift safety tips for operators, supervisors, and pedestrians.