Forklifts are indispensable in material handling operations, yet every year, workplace accidents involving forklifts result in dozens of fatalities and thousands of injuries. This makes forklift safety a critical concern for warehouse managers and safety professionals.

For managers to protect their staff, it’s essential they implement the correct forklift safety features. A well-maintained forklift, equipped with the proper safety equipment can significantly reduce the risk of accidents. In essence, prioritizing forklift safety features, alongside maintenance and productivity, is crucial for saving lives and minimizing costly downtime.

In this post, we will break down the top forklift safety features—from basic guards to smart tech tools. Understanding these can help you keep your team safe, stay compliant, and create a safer workplace for everyone.

Let’s dive in!

Essential Forklift Safety Features

Modern forklifts come equipped with a range of forklift safety products and design elements intended to keep people safe. These essential safety features can be grouped into four main categories:

- Operator Protection Systems

- Visibility and Awareness Enhancements

- Proximity and Collision Avoidance Technologies

- Load Handling and Stability Aids.

Below, we explore each category and highlight specific safety features (both built-in and add-ons) that managers shouldn’t overlook.

Operator Protection Systems

Operator protection systems are physical safeguards that protect the driver in the event of an accident or hazard. These are the foundational forklift safety equipment items that every lift truck should have:

Overhead Guard and Load Backrest

The overhead guard and load backrest are critical safety features that protect operators from falling objects and shifting loads. OSHA and ANSI standards require these guards on high-lift trucks, and managers must ensure they are intact and never removed.

Seat Belts and Operator Restraints

Seat belts are vital for operator safety during tip-overs, keeping drivers secured within the protective cage. OSHA enforces seat belt use, and employers should retrofit older forklifts and enforce strict seat belt policies.

Operator Presence Systems

Many forklifts (especially modern ones and reach trucks or order pickers) include “presence detection” features. For example, stand-up reach trucks often have a dead-man pedal or sensor mat that the operator must stand on; if the operator steps off or loses balance, the truck automatically cuts power. Likewise, sit-down lifts have seat switch interlocks that disable travel or lifting if the operator isn’t seated.

Cab Enclosures and Guards

Depending on the environment, optional features like cab enclosures, hip restraints, and mesh panels offer added protection in hazardous environments. Enclosed operator cabs with steel mesh doors or panels can protect drivers in certain hazardous applications (for instance, to keep the operator inside the cabin during a tip-over, as recommended for stand-up forklifts).

Tip: (During pre-shift inspections, include these items on your forklift safety checklist. Ensure the overhead guard has no cracks, the seat belt latches properly, and safety switches work. A quick check can catch issues before they lead to an incident.)

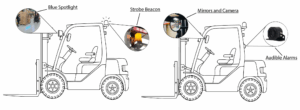

Visibility and Awareness Enhancements

Even a well-protected operator can’t avoid hazards they cannot see. Visibility and awareness enhancements are safety features that help the operator and nearby pedestrians stay aware of each other. They address the fact that forklifts often have blind spots (due to loads or design) and operate in busy, sometimes dim, environments. Key features in this category include:

Lighting Systems (Headlights, Taillights, and Warning Lights)

Proper lighting helps operators see clearly and alerts pedestrians to a forklift’s presence—especially in dimly lit areas where OSHA may require auxiliary lights. LED packages are a popular upgrade thanks to their brightness and longevity.

Blue Spotlights and Strobe Beacons

Blue spotlights, red zone lights, and flashing beacons are easy add-ons that dramatically increase pedestrian awareness—especially in areas with heavy foot traffic or background noise.(For a comprehensive look at blue lights and how they improve safety, see our post on forklift blue lights for tips on selecting and using these systems.)

Mirrors and Camera Systems

Panoramic mirrors and rear or mast-mounted cameras boost operator visibility and reduce blind spots, helping prevent collisions—especially when reversing or lifting high.

Audible Alarms and Communication

Every forklift is equipped with a horn, which operators should use liberally to announce their presence. (OSHA rules explicitly require operators to sound the horn at cross aisles and blind corners to warn others.) Beyond the horn, many forklifts have backup alarms – a beeping sound that engages when the forklift is in reverse gear.

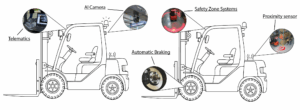

Proximity and Collision Avoidance Technologies

One of the more high-tech categories of forklift safety features includes proximity detection and collision avoidance systems. These technologies actively help prevent accidents by sensing the environment around the forklift and either warning the operator or even intervening. As warehouses embrace “smart” technology, these forklift safety systems are becoming more accessible and widespread. Key examples include:

Proximity Sensors and Pedestrian Detectors

Proximity sensor systems use technologies like ultrasound, radar, or RFID to detect when an object or person is dangerously close to the forklift. For instance, an ultrasonic proximity detection kit can be mounted on a forklift to alert the driver (with beeps or lights) if the rear of the truck is nearing a wall, rack, or person. Some systems require pedestrians to wear small transmitter tags; if a tagged person comes within a preset range (say 10 or 20 feet) of the equipped forklift, both the pedestrian and operator receive alerts (vibration, lights, or alarms).

Collision Warning and Automatic Braking

Building on sensor technology, some advanced forklifts integrate automatic braking or speed reduction features. For example, if an obstacle is detected very close and the operator doesn’t slow down, the system can automatically reduce the travel speed or even brake to a stop to avoid a crash. This goes hand-in-hand with advanced warning systems that might first flash a warning and then intervene if the operator doesn’t react.

“Safety Zone” Projection Systems

In section Visibility and Awareness Enhancements we mentioned red zone lights that mark a visual boundary on the floor. There are also more complex safety zone systems that use lasers or floor projection to delineate safe distances. Additionally, some facilities use floor-mounted lights or signs that activate when a forklift is approaching an intersection (triggered by the forklift via a sensor system).

AI Camera Systems and Object Recognition

A cutting-edge development in forklift safety is the use of AI camera systems. These are intelligent cameras mounted on the forklift that don’t just feed video, but also actively analyze it for hazards – such as identifying a person stepping into the forklift’s path or recognizing pallet positions to warn of misaligned loads. The AI can then alert the operator in real-time with visual or audible cues, or even communicate with the forklift’s controls to slow down.

Impact Monitoring and Telematics

Even with all prevention measures, incidents can happen. Forklift impact detection systems are sensors that register when a forklift has a sudden jolt or impact (for example, hitting a rack or curb). These systems often tie into a real-time monitoring and communication system that logs the event, notifies a supervisor, or even automatically slows down the forklift after a collision.

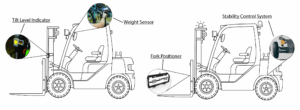

Load Handling and Stability Aids

The way a forklift handles its load has a direct impact on safety. Many accidents (especially tip-overs and falling loads) occur due to instability or improper load handling. Load handling and stability aids are features that help keep the forklift and its load secure and balanced. Managers should ensure these features are present and utilized:

Electronic Stability Control Systems

Several forklift manufacturers have proprietary systems to enhance stability. One famous example is Toyota’s System of Active Stability (SAS), which uses sensors and automatic controls to reduce the risk of tip-overs. SAS monitors factors like speed, turning radius, load weight, and mast angle over 3,000 times per second, and if it detects an unsafe condition, it will take corrective action (such as locking the rear axle or limiting the mast tilt) to stabilize the forklift.

Tilt and Lift Indicators / Controllers

Not all forklifts will have fancy active stability, but there are simpler aids that help with safe load handling. Mast tilt indicators (a gauge or digital display that shows the tilt angle of the forks) can assist operators in keeping loads level, especially at height. Some forklifts even have an automatic horizontal fork leveling system — with the press of a button, the forks automatically return to level position, which is extremely useful when stacking pallets on high racks.

Load Weight Sensors and Capacity Monitors

Overloading a forklift beyond its rated capacity can quickly lead to tipping or dropping the load. Some modern forklifts come with load weight sensors that can estimate the weight on the forks and alert the operator if it’s nearing or exceeding the truck’s capacity. Even without high-tech sensors, every forklift has a data plate that indicates its capacity at specific load centers – operators must be trained to understand this.

Attachments for Safe Load Handling

Using the right attachment for the job can significantly improve safety. For example, a fork positioner allows the operator to adjust the fork spacing without leaving the seat, which means they can properly engage a load of varying sizes without risky maneuvers. This not only improves ergonomics but prevents the temptation of “making do” with improper fork placement (which could cause a load to slip). Sideshifters, clamps, carton clamps, drum handlers, and other attachments all exist to handle specific loads more securely than standard forks alone. (Learn more in our forklift attachments guide about which attachments can improve safety and efficiency for different load types.)

Training on Load Handling Techniques

While not a physical feature, it’s worth noting that even the best load handling aids require an operator who knows how to use them. For instance, an operator should know to slow down on turns especially with a raised load, even if the forklift has stability control. They should also know to tilt the mast back slightly when carrying a load and keep loads low to the ground during travel for maximum stability. These practices, reinforced by tools like tilt locks or speed limiters, create a synergistic effect that keeps the whole operation safe.

Regulatory Compliance and Standards

Safety features are not just optional add-ons – many are mandated (or at least strongly recommended) by regulations and industry standards. Ensuring compliance with OSHA regulations and ANSI standards isn’t just about avoiding fines; it’s about meeting proven safety benchmarks.

OSHA Regulations (29 CFR 1910.178)

The Occupational Safety and Health Administration’s standard for powered industrial trucks (1910.178) lays out various safety requirements. We’ve already touched on some.

Perhaps most importantly, OSHA mandates forklift operator training and certification. Employers must ensure that each operator is trained and evaluated as competent before operating a forklift. This training must cover truck-specific topics (like operating instructions, load stability, controls, etc.) and workplace-specific topics (like surface conditions, pedestrian traffic). If new safety features are added to a forklift (say, a new type of attachment or a sensing system), that falls under training as well – operators should be instructed in their proper use.

In addition to federal OSHA rules, be mindful of any state-specific regulations (some states have their own OSHA-approved plans that might have additional requirements) and any site-specific rules (for example, some companies or sites require backup alarms on all trucks, even if not mandated by law).

ANSI/ITSDF Standards

The American National Standards Institute, in cooperation with the Industrial Truck Standards Development Foundation (ITSDF), publishes the ANSI B56 series of standards which cover safety in forklift design and operation. ANSI B56.1 (Safety Standard for Low Lift and High Lift Trucks) is a key consensus standard that manufacturers and many companies adhere to. While ANSI standards themselves aren’t law, OSHA often looks to them as industry best practices (and OSHA has adopted portions of older ANSI B56.1 into the 1910.178 regulation).

Key Takeaway: Regulatory compliance isn’t separate from the topic of safety features – it’s directly related. Overhead guards, load backrests, seat belts, lights, alarms, and training are all either mandated or strongly emphasized by OSHA/ANSI. Non-compliance can result in penalties, but more critically, it means your operation is at greater risk of an accident. It’s far better to proactively comply and even exceed these standards.

Conclusion

Forklift operations come with inherent risks, but these can be significantly reduced through the consistent application of proper safety features and practices. From foundational elements like seat belts and overhead guards to advanced technologies such as proximity sensors and stability controls, every feature plays a vital role in protecting both operators and pedestrians.

Compliance with OSHA and ANSI standards is just the beginning—true safety requires a culture where awareness and training are part of daily operations. Investing in safety not only minimizes the risk of accidents but also enhances efficiency, reduces costly disruptions, and boosts team confidence.

Managers must view safety as a holistic, ongoing commitment that integrates equipment, environment, and people. By proactively maintaining equipment, retrofitting older models, and encouraging open communication, leaders foster a safer, more productive workplace. Prioritizing forklift safety isn’t just a regulatory obligation—it’s a strategic decision that reflects foresight, leadership, and a genuine commitment to operational excellence.