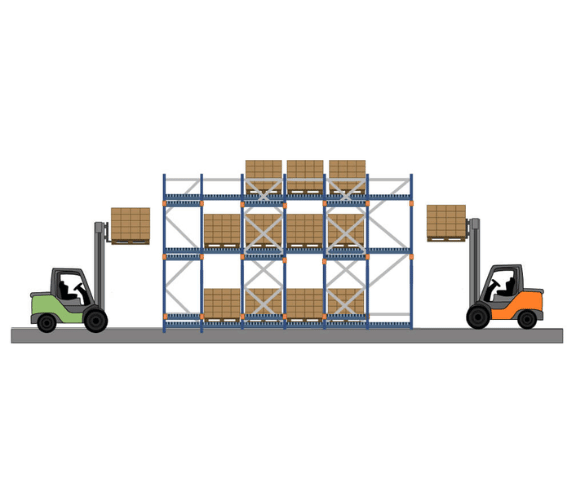

In a drive-in racking system, forklifts enter the racking’s interior at a single entry point to place pallets.

Operators place each pallet at the rear of the racking, working their way with each pallet back toward the entry point.

When unloading, operators perform the opposite procedure. That is, working their way back into the interior of the racking with each pallet removal.

This racking system is best for Last-In, First-Out (LIFO) inventory management and operations with high volumes and few SKUs.