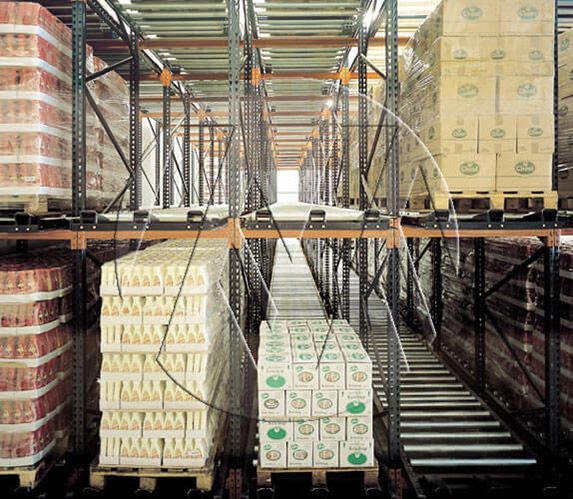

In a pallet flow racking system, horizontal beams are installed at a slight angle and fitted with rollers.

Forklift operators load pallets into the high end of the roller tracks and they move by gravity toward the low end.

When the first pallet is removed, the others advance one position. This ensures that the front pallet position is always filled.

This racking system is ideal for First-In, First-Out (FIFO) inventory management, like those involving date-sensitive inventory such as food and pharmaceuticals.