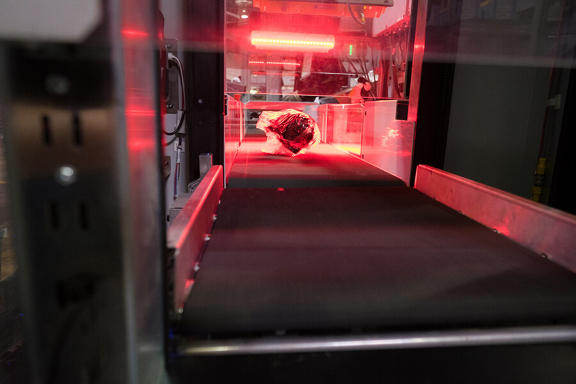

Improve Warehouse Flow, Productivity, Efficiency, and Reliability with Our Sortation Conveyor Systems

Do you need a material handling system that can help you:

- Sift, separate, or arrange different products before sending them to other downstream processes?

- Handle high product quantity flows?

- Adapt to your floor plans, product specifications, and anticipate growth?

With Conger’s expert guidance, we can design a sortation system to help you with all those needs and much more!