When it comes to types of forklifts, understanding the different options available, such as counterbalance forklifts, rough terrain forklifts, and electric motor rider trucks, ensures businesses choose the right forklift truck for their needs.

Whether navigating narrow aisles with electric motor narrow aisle forklifts or tackling rough terrain with pneumatic tire forklifts, selecting the appropriate forklift type is crucial for maximizing efficiency and safety in material handling operations.

Let’s dive in!

Different Types of Forklifts

By Power Source

Electric Motor Forklifts

Battery-powered forklifts ideal for indoor use. They offer quiet operation and zero emissions. These forklifts are perfect for environments where noise and air quality are concerns, like warehouses. Electric motor forklifts have lower maintenance costs than internal combustion engine trucks. They come in various designs, such as sit down riders and stand up trucks, catering to different needs.

Internal Combustion Engine Forklifts

Internal combustion engine trucks, powered by gasoline, diesel, or propane, are designed for heavy loads and are suitable for diverse applications, both indoors and outdoors. Internal combustion engines, particularly when used with cushion tires, offer performance benefits such as enhanced maneuverability and comfort in tight spaces while maintaining efficiency.

By Tire Type

Cushion Tire Forklifts

Designed for smooth indoor surfaces, offering compact maneuverability.

Pneumatic Tire Forklifts

Suitable for rough outdoor terrain, providing better traction and durability.

By Design and Functionality

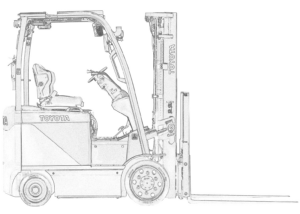

Counterbalance Forklifts

These forklifts have a simple, versatile design with front-mounted forks and a rear counterweight. They are common in warehouses and loading docks. Counterbalance forklifts are renowned for their straightforward operation and ability to handle various material handling tasks. With their ability to lift heavy loads efficiently, they are a staple in manufacturing and distribution centers. Their design allows operators to drive up directly to the load, making them ideal for unloading pallets from delivery trucks and transporting them across storage facilities.

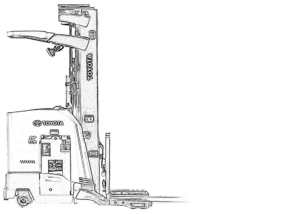

Reach Trucks

Designed for narrow aisles, reach trucks have extendable forks that allow them to access high shelves efficiently. These forklifts are perfect for maximizing vertical storage space in warehouses with limited floor area. Reach trucks are equipped with advanced technology, such as cameras and sensors, to enhance precision when accessing high storage racks. Their compact build and excellent maneuverability make them indispensable in environments where space optimization is crucial, such as in retail stockrooms and cold storage facilities.

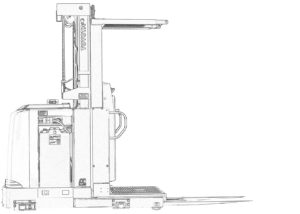

Order Pickers

Unlike standard forklifts, order pickers lift operators to retrieve individual items, making them ideal for inventory management and order fulfillment. These forklifts are essential in e-commerce warehouses where quick and accurate order picking is vital. Order pickers are designed with safety features like harnesses and guardrails to ensure operator safety at elevated heights. Their ergonomic controls and adjustable platforms enhance productivity by allowing operators to work comfortably and efficiently.

Side Loaders

Loader forklifts, including side loaders, have forks on the side, allowing them to carry long materials like timber, pipes, and steel efficiently. They are particularly useful in industries dealing with bulky and lengthy materials, such as lumberyards and metal fabrication facilities. Side loaders excel in narrow aisles and can navigate tight spaces where traditional forklifts might struggle. Their ability to load and unload from the side reduces the need for excessive maneuvering, streamlining operations in crowded storage areas.

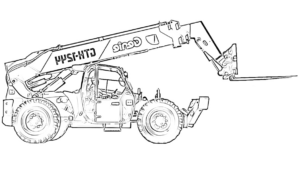

Telescopic Handlers (Telehandlers)

These forklifts combine a forklift’s lifting capability with a crane’s reach. Their extendable boom makes them useful for construction and agricultural tasks. Telescopic handlers are versatile machines capable of performing multiple functions, such as lifting, moving, and placing materials at varying heights and distances. They are often equipped with attachments like buckets and winches, further expanding their functionality. Telehandlers are a common sight on construction sites, where they assist in lifting loads to elevated work areas and transporting materials over rough terrain.

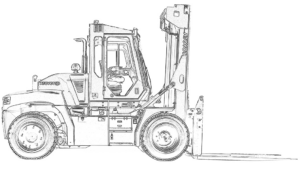

Rough Terrain Forklifts

Rough terrain forklift trucks, designed with large tractor-style tires and diesel engines, are built to navigate challenging terrains such as construction sites and lumberyards. These forklifts are engineered for durability and stability on uneven surfaces, making them ideal for outdoor applications. Rough terrain forklifts are equipped with powerful engines and reinforced frames to handle heavier loads in demanding environments. They are essential for transporting construction materials, such as bricks and concrete, across rugged job sites efficiently.

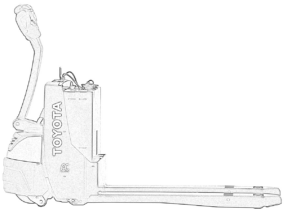

Pallet Jacks

Pedestrian operated pallet trucks, both manual and electric, are essential tools in warehouses and retail environments. They feature forks that slide beneath pallets and use hydraulic jacks for lifting, making them ideal for moving palletized loads over short distances. Pallet jacks are cost-effective and easy to operate, providing a practical solution for low-level material handling tasks. Electric pallet jacks offer additional power and efficiency, reducing the physical strain on operators and increasing productivity in high-volume settings.

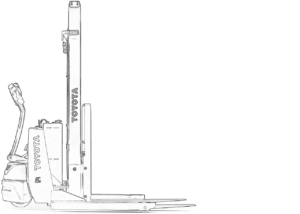

Walkie Stackers

Walkie stackers are pedestrian-controlled forklifts designed for stacking pallets in small warehouses and storerooms. They are an economical alternative to larger forklifts and are perfect for operations with limited space and budget constraints. Walkie stackers provide precise control and are equipped with features like adjustable forks and mast heights to accommodate various pallet sizes. Their compact design and ease of use make them a popular choice for businesses looking to optimize their storage capabilities without investing in larger equipment.

Warehouse Forklifts

Warehouse forklifts are compact and easy to maneuver in tight warehouse spaces, ideal for loading and unloading trucks. These forklifts are versatile and can handle a wide range of tasks, from transporting goods within the warehouse to assisting with inventory management. Warehouse forklifts are available in different configurations, including sit-down and stand-up models, to suit specific operational needs. Their efficient design and adaptability make them a valuable asset in any warehouse operation, ensuring smooth and efficient material handling processes. Turret trucks, specifically designed for narrow aisles, are ideal for maximizing storage in high-density environments.

Specialized Forklifts

Specialized forklifts are designed to handle specific tasks and environments, tailored to meet the unique needs of various industries and applications. These forklifts offer solutions for particular challenges, ensuring efficiency and safety in specialized material handling operations.

7 Different Types of Forklifts

Also referred to as the seven classes of forklifts, these categories are defined by OSHA and include the following:

Class I – Electric Motor Rider Trucks

- Power Source: Electric motor

- Key Features: Quiet operation, zero emissions

- Configurations: Sit-down or stand-up models

- Best Use: Indoor applications (e.g., warehouses), especially where narrow aisles require tight maneuvering

Class I forklifts are electric motor rider trucks ideal for indoor environments due to their quiet operation and zero emissions. They are versatile, with configurations like sit-down and stand-up models, making them perfect for navigating narrow aisles in warehouses

Class II – Electric Motor Narrow Aisle Trucks

- Power Source: Electric motor

- Key Features: Narrow aisle design, articulated masts

- Primary Advantage: Maximizes storage in high-density warehouses

- Best Use: Environments with limited space needing efficient aisle navigation

Class II forklifts are designed for narrow aisle applications, maximizing storage capacity with advanced features like articulated masts. They are essential in high-density warehouses where space optimization is crucial.

Class III – Electric Motor Hand Trucks

- Power Source: Electric motor (pedestrian-operated)

- Key Features: Simple controls, compact, cost-effective

- Primary Advantage: Easily moves palletized loads short distances

- Best Use: Crowded storage areas, small-scale load handling

Class III forklifts, also known as electric motor hand trucks or pallet jacks, are pedestrian-operated and used for moving palletized loads over short distances. They are cost-effective and easy to operate, ideal for crowded storage areas.

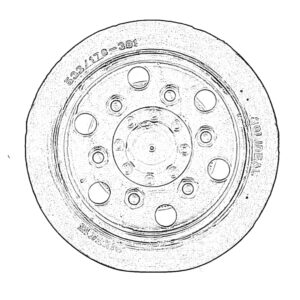

Class IV – Internal Combustion Engine Forklifts with Cushion Tires

- Power Source: Internal combustion engine

- Tire Type: Cushion tires (smooth surfaces)

- Key Features: Enhanced maneuverability indoors

- Best Use: Heavy load handling in warehouses or facilities with even flooring

Class IV forklifts are internal combustion engine trucks with cushion tires, designed for indoor use on smooth surfaces. They offer enhanced maneuverability and are suitable for heavy load operations in warehouses.

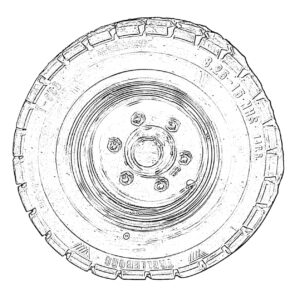

Class V – Internal Combustion Engine Forklifts with Pneumatic Tires

- Power Source: Internal combustion engine

- Tire Type: Pneumatic tires (suitable for rough or uneven terrain)

- Key Features: Higher ground clearance, robust design

- Best Use: Outdoor operations or challenging environments requiring heavier lifting

Class V forklifts are equipped with pneumatic tires, making them ideal for outdoor applications and rough terrain. They provide the power needed to handle heavier loads in challenging environments.

Class VI – Electric and Internal Combustion Engine Tractors

- Power Sources: Electric or internal combustion engine

- Primary Function: Towing loads

- Key Features: Designed to move multiple loads simultaneously

- Best Use: Industries requiring bulk transport (e.g., airports, distribution centers)

Class VI forklifts include electric and internal combustion engine tractors designed for towing loads. They are used in industries where moving multiple loads simultaneously is necessary.

Class VII – Rough Terrain Forklifts

Power Source: Typically internal combustion engine

Tire Type: Large, heavily treaded tires

Key Features: Built for stability on uneven surfaces

Best Use: Outdoor worksites with challenging terrains (construction sites, lumber yards)

Class VII forklifts are rough terrain forklift trucks built for outdoor worksites with challenging terrains. They are equipped with large tires and powerful engines to navigate uneven surfaces safely.

Choosing the Right Forklift

Choosing the right forklift for your business can be a daunting task, especially with the numerous options available. However, by considering several key factors, you can make an informed decision that meets your specific needs and enhances your operational efficiency.

When selecting a forklift, consider the following factors:

- Lift Capacity: Determine the maximum weight and size of the loads you need to lift. This will help you choose a forklift with the appropriate lifting capacity, ensuring it can handle your heaviest loads without compromising safety or performance.

- Terrain and Environment: Consider the terrain and environment in which the forklift will operate. Rough terrain forklifts are designed for outdoor use on uneven surfaces, making them ideal for construction sites and lumberyards. In contrast, counterbalance forklifts are better suited for indoor use on smooth surfaces, such as in warehouses and manufacturing facilities.

- Fuel Type: Decide whether you need an electric, gas, or diesel-powered forklift. Electric forklifts are ideal for indoor use due to their quiet operation and zero emissions, while internal combustion engine trucks are better suited for outdoor use and can handle heavier loads.

- Narrow Aisles: If you need to operate in narrow aisles, consider a forklift with a compact design, such as a pedestrian operated pallet truck or a turret truck. These forklifts are specifically designed to navigate tight spaces, maximizing storage capacity and efficiency.

- Heavy Loads: If you need to lift heavy loads, consider a forklift with a high lifting capacity, such as a loader forklift or a heavy-duty forklift. These forklifts are built to handle the most demanding tasks, ensuring your operations run smoothly.

- Forklift Classifications: Familiarize yourself with the different forklift classifications, such as Class I (electric motor rider trucks) and Class VII (rough terrain forklift trucks). Understanding these classifications will help you choose a forklift that meets your specific needs and complies with industry standards.

- Maintenance and Repair: Consider the maintenance and repair requirements of the forklift. Some forklifts, such as electric forklifts, require less maintenance than others, potentially reducing downtime and operational costs.

- Operator Comfort and Safety: Consider the comfort and safety of the operator. Look for forklifts with features such as ergonomic controls, comfortable seating, and advanced safety features. Ensuring operator comfort and safety can lead to increased productivity and reduced risk of accidents.

By considering these factors, you can choose a forklift that meets your specific needs and helps you achieve your business goals. Whether you need a forklift for indoor or outdoor use, for handling light or heavy loads, understanding these key considerations will guide you in making the best choice for your operations.

Frequently Asked Questions (FAQs)

What are the different types of forklifts?

Forklifts can vary based on tires, fuel type, and intended application, but the most widely recognized breakdown is OSHA’s seven forklift classes. This classification system groups forklifts according to their power sources, design features, and typical work environments.

How many types of forklifts are there?

While there are countless forklift models (with new ones introduced regularly) every forklift fits into one of the seven OSHA forklift classes. Choosing the right one can be challenging, so consult your local dealer or an expert to identify the specific model that best meets your needs.

What is the most common type of forklift?

Counterbalance forklifts are the most widely used due to their versatility.

Which forklifts are best for narrow aisles?

Reach trucks and order pickers are ideal for tight warehouse spaces.

Are electric forklifts better than gas-powered ones?

Electric forklifts are quieter and emission-free, making them suitable for indoor use, while gas-powered models handle heavier loads and outdoor conditions better.

Conclusion

Forklifts play a crucial role in material handling, with various types designed for specific applications. Choosing the right forklift depends on load capacity, environment, and operational needs. Understanding these differences ensures businesses invest in the most efficient equipment for their workflow.