This is your complete guide to aerial lift inspections.

In it, you’ll learn:

- The rules for boom and scissor lift inspections (from OSHA and ANSI).

- How often inspections are required?

- The different types of inspections.

- What’s involved in each type of inspection?

- And lots more!

Let’s dive in!

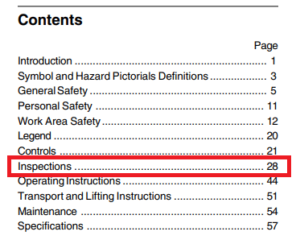

Table of Contents

Why Are Aerial Lift Inspections Necessary?

There are at least three reasons that aerial lifts need an inspection.

For one, aerial lift inspections help to ensure pedestrian and operator safety.

After all, aerial lifts can be dangerous if they’re not operationally sound.

Also, aerial lift inspections help improve the longevity of the equipment and reduce costs.

That is because detecting defects early allows for repairs to be made before they balloon into more costly issues.

And finally, inspections are required by ANSI and OSHA.

(We’ll cover that more in the next section.)

What Rules Govern Aerial Lift Inspections?

Two bodies provide the rules for aerial and scissor lift inspections:

- OSHA (the Occupational Safety and Health Administration)

- ANSI (the American National Standards Institute)

Not sure what the difference is?

To clear up any confusion, we’ll cover that next.

What’s the Difference Between OSHA Regulations and ANSI Industry Standards?

OSHA regulations are laws, which means they are subject to government enforcement.

ANSI standards, however, are not laws.

Instead, they are the industry guidelines for aerial lift design, operation, and safety.

So, does that mean you don’t have to follow ANSI’s standards?

Not necessarily.

OSHA often incorporates ANSI rules by reference, which means they can carry the force of law.

So ensure you follow both OSHA and ANSI’s rules on aerial lifts, including inspections.

What Are the OSHA and ANSI Regulations for Aerial Lifts Inspections?

OSHA Boom Lift Safety Requirements

The OSHA regulations for boom inspections are in the following standards:

- 1910.67 – Vehicle-mounted elevating and rotating work platforms.

- 1926.453 – Aerial lifts.

- 1926.502 – Fall protection systems criteria and practices.

What do these standards say exactly?

OSHA standards state that you must:

-

Test the lift controls before using the equipment to ensure they’re in proper working order (1910.67(c)(2)(i))

-

Ensure the boom and outriggers are in the stowed position before moving the lift (1910.67(c)(2)(xii))

-

Instruct workers in how to recognize, avoid, and eliminate any hazards they may come across (1926.21(b)(2))

-

Inspect personal fall arrest devices to ensure they’re free from wear and damage before using (1926.502(d)(21))

Now, that isn’t all of what OSHA requires for these inspections.

Fortunately, their convenient FactSheet on aerial lifts provides more detailed inspection requirements.

OSHA Scissor Lift Inspection Requirements

It’s important to note that scissor lifts aren’t technically considered aerial lifts.

Instead, OSHA regards scissor lifts as scaffolding.

In an interpretation letter, OSHA states that:

“Although no OSHA provisions specifically address scissor lifts, they meet the definition of a scaffold (§1926.451 – general requirements for scaffolds) in Aerial lifts standards 1926.453 Subpart L.”

This statement indicates that scissor lifts have different inspection requirements than boom lifts and other aerial lift types.

The standards for scissor lift inspections are 1915.71 – Scaffolds or Staging and 1926.451 – General requirements (for scaffolding).

Some of the key scissor lift inspection requirements in these standards include:

-

Only a competent person should inspect scaffolds and scaffold components for visible defects before each work shift (1926.451(f)(3))

-

Maintain scaffolds in a safe and secure condition and replace any damaged, broken, burdened, or defective scaffold component (1915.71(b)(5))

-

Inspect metal scaffold members and maintain them in good repair and free of corrosion (1915.71(d)(1))

-

Only a competent person should inspect ropes for defects before each work shift and after every incident that can affect a rope’s integrity. Replace ropes with affected integrity (1926.451(d)(10))

-

Inspect clips and tighten loose ones to the manufacturer’s recommendations before and after each work shift (1926.451(d)(12)(iv))

ANSI Standards for Aerial and Scissor Lifts

The ANSI standards for aerial and scissor lifts are on ANSI’s website:

- ANSI/SIA A92.2-1969 – Vehicle-Mounted Elevating and Rotating Work Platforms.

- ANSI/SIA A92.3 – American National Standard For Manually Propelled Elevating Aerial Platforms.

- ANSI/SIA A92.5 – American National Standard Boom-Supported Elevating Work Platforms.

- ANSI/SIA A92.6 – American National Standard For Self-Propelled Elevating Work Platforms.

Unfortunately, they are not free.

So you’ll need to purchase each standard or a bundle of them to review the specific requirements.

However, we can still provide a brief overview of their requirements:

- Aerial lift inspections are required before each use.

- Frequent Aerial lift inspections are necessary.

- Annual Aerial lift inspections are mandatory.

Obviously, these rules are a little vague.

But don’t worry – we’ll talk more about them in the “How Often Should Aerial Lifts Be Inspected” section below.

Are There Any Other Rules Governing Aerial Lift Inspections?

The answer is yes.

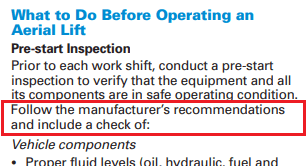

Besides OSHA and ANSI, manufacturers specify the boom and scissor lift inspection items and how often to perform them.

OSHA notes that you need to follow the specific instructions:

How do you know where to find the manufacturer’s inspection recommendations?

Check the owner’s manual:

How Often Should Aerial Lifts Be Inspected?

There are three main inspection intervals:

- Pre-start inspections.

- Frequent inspections.

- Annual inspections.

Additionally, some boom lifts require additional inspections.

We’ll cover each of these intervals in more detail below.

Pre-Start Inspections

OSHA requires that operators perform a pre-start inspection before using the lift.

At a high level, this should consist of a:

- Visual inspection of the lift

- Inspection of the work zone

- Test of function controls

The purpose of this inspection is to:

- Ensure all parts of the equipment are in safe operating condition.

- Identify any required lift maintenance actions.

We’ll cover pre-start inspections in more detail in the section below called “How Do You Inspect an Aerial Lift?”

Frequent Inspections

You’re probably wondering, how often is “frequent”?

The answer is “frequent” inspections are required when:

- The lift was purchased as used equipment unless it is up-to-date on frequent and annual inspections.

- The lift has been in service for three months, or 150 hours – whichever comes first.

- The lift has been out of service for more than three months.

Annual Inspections

If you’re wondering, “What are the OSHA aerial lift annual inspection requirements?” the answer is that OSHA doesn’t specify.

Instead, the ANSI establishes the annual inspection requirements.

And recall that OSHA sometimes incorporates ANSI rules into the law.

So, you should follow what ANSI says on the topic.

Now, what does ANSI say about annual inspections?

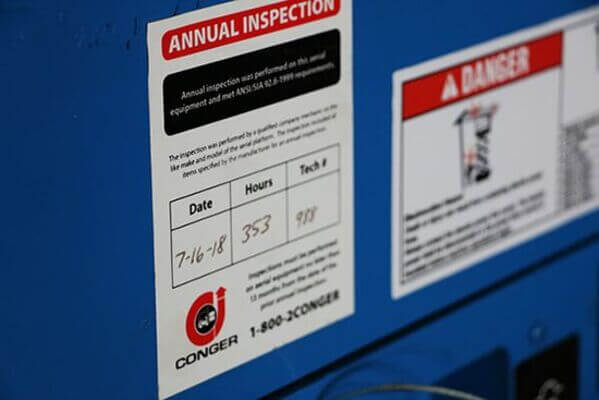

They state annual inspections must be performed at most thirteen months after the previous inspection.

Not sure when your aerial lift last had an annual inspection?

You can typically find out when the last inspection was by checking the date posted on the lift:

Additional Inspections

Specific boom lift models may have additional inspection requirements:

- Booms with chain extension and retraction units need these vehicle components inspected every two years.

- Booms with wire ropes must have the wire ropes replaced every 12 years or after 7,000 service hours.

Who Can Perform Aerial Lift Inspection?

OSHA states that “competent” persons should conduct aerial lift inspections.

That begs the question: Who is a “competent” person?

Fortunately, OSHA provides an answer to this question in 1926.450:

“Competent person means one who is capable of identifying existing and predictable hazards in the surroundings or working conditions which are unsanitary, hazardous, or dangerous to employees, and who has authorization to take prompt corrective measures to eliminate them.”

They also give more information in this letter of interpretation.

A competent person has the training and knowledge specific to the equipment’s operation and safety precautions.

So, equipment operators may be considered competent to carry out pre-start inspections.

However, repairs, as well as frequent and annual inspections, should be conducted by qualified technicians.

These technicians must be familiar with the particular type of aerial platform or one with similar design characteristics (per ANSI A92.5 section 6.6 and A92.6).

How Do You Inspect an Aerial Lift?

We assume you are reading this article as a boom or scissor lift operator, whether prospective or current. Therefore, we’ll limit this section to pre-start inspections only.

After all, only professional technicians should perform frequent and annual inspections.

Recall that your aerial lift manufacturer specifies which areas to inspect.

That said, the following inspection checklists are brief overviews to give you an idea of what each inspection involves.

Always check your specific aerial lift’s owner’s manual for the required inspection items.

Pre-Start Inspections For Boom Lifts

Boom lift pre-start inspection should consist of a:

- Visual inspection

- Function test (for ground and platform controls)

- Aerial work zone inspection

So if you’re wondering “how do you inspect a boom lift?”, you can use this aerial lift pre-use inspection checklist as a guide:

1. Visual Inspection

- All safety manuals should be legible and present in the platform storage container

- All decals must be legible and present

- Check for fluid leaks and fluid levels. It should include hydraulic oil, battery fluid, engine oil, and coolant (internal combustion models).

- Ensure the battery is charged (electric models)

- Check components for presence, damage, improper installation, and modifications, including:

- Electrical wires and cables

- Hydraulic tank, hoses, fittings, cylinders, and valves

- Motors and hubs

- Wear pads

- Wheels and tires

- Limit switches and horn

- Any equipped alarms or beacons

- Engine components and fuel tank (internal combustion models)

- Fasteners

- Safety rails and gates

- Structural components for cracked welds, dents, and excessive rust or corrosion

2. Function Test

Ground Control Testing

- Ensure that the emergency stop button on the ground controls effectively cuts off power to the lift and prevents its operation.

- Confirm that the switch functions when engaged and does not operate when disengaged.

- Test the tilt sensor to ensure the alarm activates when pushed to the side.

- Check the auxiliary controls to ensure they operate as intended.

Platform Control Testing

- Ensure the emergency stop button on the platform controls effectively cuts off power to the lift and prevents its operation.

- Sound the horn to verify its functionality.

- Check the footswitch and ensure it activates when depressed and deactivates when released.

- Test the steering mechanism to ensure proper functionality.

- Test the brakes and verify they can stop the lift and securely hold the machine.

- Test the drive system to ensure it operates as intended.

- Verify that the machine moves within its speed limit when the boom arm is raised or extended.

- Test the auxiliary controls to ensure they operate correctly.

3. Work Zone Inspection

Inspect your work area for any conditions that would present a hazard to operating your boom lift, including:

- Drop-offs, holes, bumps, and debris.

- Slopes and slippery surfaces.

- Overhead obstructions, especially power lines.

- Weak flooring that’s unable to withstand the machine’s weight.

- Weather and wind.

- Unauthorized personnel.

Pre-Start Inspections For Scissor Lifts

Pre-start inspection items for scissor lifts are nearly the same as boom lifts.

They should consist of a:

- Visual inspection

- Function test (ground and platform controls)

- Work zone inspection

The items for each should include:

1. Visual Inspection

- All safety manuals should be legible and present in the platform storage container.

- All decals are legible and present.

- Check for fluid levels and leaks, including hydraulic oil, battery fluid, engine oil, and coolant (internal combustion models).

- Ensure the battery is charged (electric models).

- Check components for presence, damage, improper installation, and modifications, including:

- Battery packs and connectors (electric models)

- Electrical wires and cables

- Hydraulic tank, hoses, fittings, cylinders, and valves

- Motors and hubs

- Wear pads

- Wheels and tires

- Limit switches and horn

- Any equipped alarms or beacons

- Engine components and fuel tank (internal combustion models)

- Fasteners

- Safety rails, gates, and latches

- Safety arm

- Pothole protectors

- Platform extensions

- Structural components for cracked welds, dents, and excessive rust or corrosion

- Ensure the battery and component side trays are closed and latched before operating aerial equipment.

2. Function Test

Ground Control Testing

- Ensure the emergency stop button at the ground controls shuts off power to the lift and prohibits the functions.

- Test the up/down platform controls to ensure they work.

- Ensure the platform descent alarm sounds when the platform lowers.

- Test the manual auxiliary lowering lever so that it can lower the platform.

Platform Control Testing

- Ensure the emergency stop button at the platform controls shuts off power to the lift and prohibits the use of the functions.

- Sound the horn to verify it works.

- Check the function enable switch to ensure functions work when it’s engaged and don’t when it’s disengaged.

- Test the up/down platform controls to ensure they work properly.

- Ensure the pothole protectors engage when the platform raises.

- Test the steering to ensure it works.

- Test the brakes to ensure they stop the lift and hold the machine in place.

- Check the tilt sensor operation by driving on raised woodblocks, elevating the platform, and ensuring the lift doesn’t move while elevated and tilted (Note: Test this using the platform controls but while standing on the ground).

- Check the drive speed limit to ensure the machine moves within its speed limit when the platform is raised.

- Test the pothole protectors to ensure they deploy, can’t be moved while deployed, and return to the stowed position.

3. Work Zone Inspection

Inspect your work area for any conditions that would present a hazard to operating your boom lift, including:

- Drop-offs, holes, bumps, and debris

- Slopes and slippery surfaces

- Overhead obstructions, especially power lines

- Weak flooring that’s unable to withstand the machine’s weight

- Weather and wind

- Unauthorized personnel

Conclusion

That’s it: The complete guide to aerial lift inspections.

Now armed with the knowledge of aerial lift inspections, be sure to inspect your equipment to ensure it is safe and compliant. If you need assistance with an aerial lift inspection, be sure to reach out to your local dealer. Conger has locations in Green Bay, Neenah, Wausau, and Richfield, Wisconsin, and offer comprehensive inspection services to keep your operations running smoothly.