Aerial lifts have become essential tools on modern construction sites. From erecting steel frames and installing utilities to interior finishing, contractors today face increased pressure to deliver projects quickly, safely, and within budget.

These powerful machines – also known as construction lift equipment – enable workers to perform tasks efficiently and securely at heights previously challenging or hazardous to access.

In this article, we’ll examine why aerial lifts are vital for job sites of all scales, highlighting their role in boosting productivity, ensuring compliance, and driving cost savings.

Let’s dive in!

Enhanced Safety on Construction Sites

Working at height is extremely dangerous – in 2023, falls to a lower level accounted for 421 of 1,075 construction fatalities. Aerial lifts help reduce this risk by providing stable platforms with guardrails and built-in tie-off points for harnesses, significantly lowering the chance of falls and injuries compared to ladders or scaffolding.

Using aerial lifts also helps job sites stay compliant with safety regulations. OSHA requires everyone working from an aerial lift to use a personal fall arrest system (typically a harness and lanyard) and remain tied off at all times. Operators must be properly trained and equipment should be inspected regularly to ensure lift usage meets OSHA standards and to prevent costly safety violations.

Another safety benefit of aerial lifts is the secure access they provide to elevated, hard-to-reach areas. Instead of climbing or balancing precariously, workers can be lifted directly to the work area in a protected platform or basket.

Articulating boom lifts, for example, can maneuver over obstacles to position workers exactly where needed. Telescopic boom lifts even offer horizontal outreach up to 90 feet, allowing safe access to spots that might be impossible to reach with scaffolding. By using the right aerial lift for the task, crews can approach heights and awkward angles with far less risk.

Improved Efficiency and Productivity

In addition to improving safety, aerial lifts greatly speed up work at height. They can be set up and repositioned in minutes, whereas assembling scaffolding or repeatedly moving ladders can take hours. In fact, most jobs can be completed in the same or less time with fewer workers by using an aerial lift.

For example, a high-wall cleaning task that needs four workers and over three hours with scaffolding can be finished by two workers in under two hours using a lift.

Aerial lifts also excel in mobility, as many self-propelled models can be driven across a job site without fully lowering the platform for each move. In fact, modern scissor and boom lifts can even be driven at full height, allowing crews to quickly relocate and resume work at the next spot without time-consuming teardown. This efficient mobility means less idle time and more continuous productivity throughout the day.

Versatility Across Various Construction Applications

Aerial lifts are used in many different construction scenarios. On both large commercial sites and smaller residential projects, they assist with tasks ranging from structural framing to final finish work. For example, scissor lifts are often used for indoor trades like electrical, HVAC, plumbing, and painting, while boom lifts handle exterior jobs such as steel erection, window installation, and façade painting.

Aerial lifts are also common beyond construction. Facilities use them for maintenance tasks like window washing or changing high light bulbs, and inspectors rely on lifts to access bridges and other structures safely.

Types of Aerial Lifts

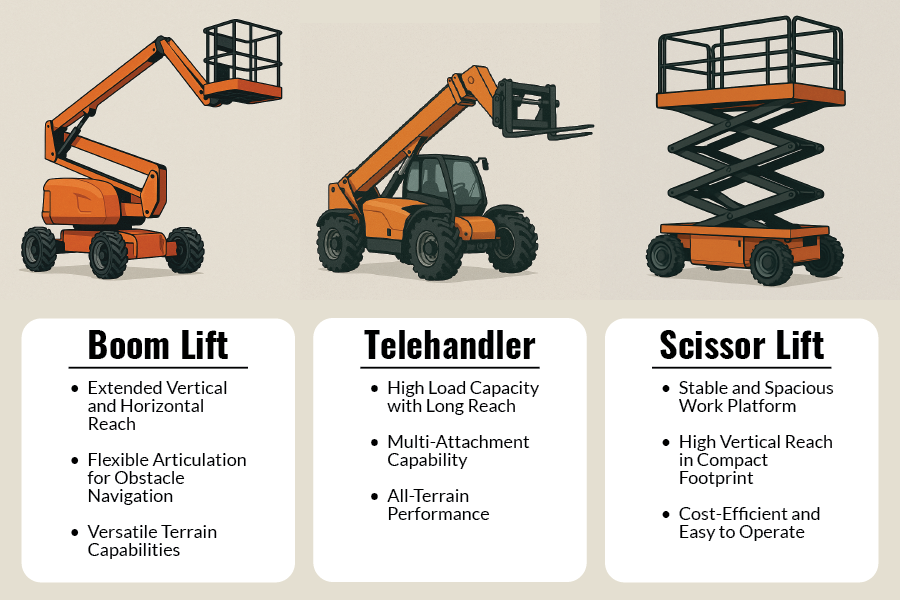

Construction teams can choose from several categories of lift equipment, each suited to different needs:

- Boom Lifts: Telescoping or articulating boom lifts that can reach extreme heights (some models offer over 130 feet of working height) and provide horizontal outreach. Boom lifts are ideal for large outdoor projects or for accessing elevated areas over obstacles.

- Scissor Lifts: Platforms that extend straight up via crossed supports (the “scissor” mechanism). Scissor lifts provide stable, spacious platforms and high weight capacities – smaller electric scissor lifts typically support around 500 lbs, while heavy-duty models can handle up to 4,000 lbs. They are perfect for tasks like indoor installation or maintenance work where multiple workers or materials need to be lifted vertically.

- Telehandlers: Telescopic handlers (sometimes called telescopic forklifts) that combine the lifting power of a forklift with the reach of a small crane. Telehandlers are used mainly for lifting and placing heavy materials (pallets of supplies, trusses, steel beams) to elevated locations and can easily traverse rough terrain.

With so many options available, it’s important to match the right type of lift to each task. Choosing the appropriate equipment – whether it’s a compact electric lift for indoor work or a rough-terrain boom for outdoors – ensures the job gets done efficiently and safely.

Cost-Effectiveness and Financial Advantages

Beyond safety and performance benefits, aerial lifts can also have positive financial impacts. One major advantage is flexibility in acquisition: you can rent lift equipment as needed instead of buying it outright. Renting avoids the big upfront purchase cost and removes many ongoing ownership expenses.

By renting, contractors avoid tying up capital and paying for year-round storage, maintenance, or insurance on an idle machine, dramatically lowering overhead costs.

Using rental equipment can also minimize downtime. Rental companies keep their lifts in peak condition and handle maintenance and repairs. If a rented lift does break down, the provider can supply a replacement quickly to keep the project on schedule.

Faster project completion means lower labor costs, and fewer accidents lead to less money lost to delays or insurance claims. Avoiding major capital expenditures by renting also improves contractors’ cash flow.

Choosing the Right Aerial Lift for Your Construction Needs

Evaluate the height, terrain, and weight requirements of your project when selecting a lift. For example, a multi-story building may need a boom lift with 100+ feet of reach; rough, uneven ground might demand a 4×4 telehandler or rough-terrain scissor lift; and lifting heavy materials requires a model with sufficient load capacity (some lifts can handle several thousand pounds).

Another key decision is whether to rent or buy the lift. Renting is often most economical for short-term or occasional needs, since it avoids a large upfront cost and maintenance responsibility. Buying can pay off if the lift will be used constantly, but it requires a significant investment and ongoing upkeep.

It’s also wise to source equipment from a reliable provider, as a reputable dealer or rental company will supply well-maintained, safety-inspected lifts along with expert support. For example, Conger offers a wide range of lift equipment and provides expert guidance and training so contractors can choose the right lift and use it safely. Partnering with a trusted provider gives peace of mind that the equipment will perform as expected and that any service needs will be handled promptly.

Conclusion

Aerial lifts have revolutionized modern construction by making elevated work safer, faster, and more cost-efficient – they are now essential tools on job sites. By choosing the right construction lift equipment for each project and following strict safety practices, contractors can maximize productivity while protecting their workers. In the long run, embracing aerial lift technology leads to safer working conditions, lower overall costs, and more profitable outcomes for construction projects of all sizes.