If you’re wondering what a forklift load center is, you’re in the right place.

Because this article explains everything you know about them, including:

-

What and where the load center is

-

How to calculate forklift load centers

-

How to determine how much a forklift can lift

-

And much more!

Let’s dive in!

Quick Summary

Don’t have time to read the whole article? Here’s a quick summary of the main points:

- Forklift load center is the distance between the face of the forks (the vertical part) and the center of gravity of the load

- The center of gravity refers to an imaginary point in an object where all of its weight is concentrated

- The forklift load center concept is important because if the load you’re lifting exceeds it, you can tip the forklift over

- You can find the forklift load center rating on the data plate

- Most forklifts are rated with a 24-inch load center. But the load center can be any measurement, depending on the type of load that the forklift handles

- You can use the following calculation to determine the lifting capacity of your forklift: Rated load center ÷ Actual load center x Rated capacity of the lift

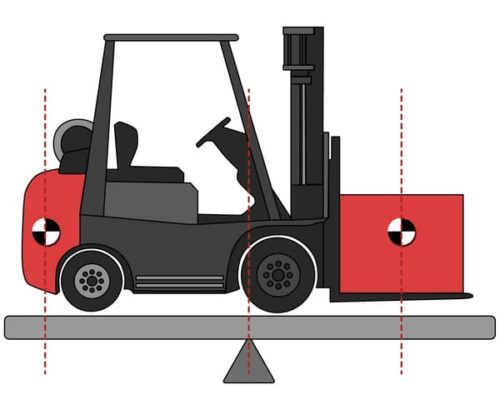

How Forklifts Work: The “Seesaw” Analogy

To understand what a forklift load center is, we first have to understand how a forklift works.

The easiest way to do this is to think of a forklift as a seesaw.

And just like a seesaw, forklifts have two “riders” and a pivot point:

-

The pivot point on a counterbalance truck is the front axle

-

The counterweight is one rider on the seesaw

-

The load is the other rider

Want to learn more about how forklifts work?

We’ve covered that topic in much greater detail in our Forklift Weight Capacity article. Check it out!

So Where Does the Load Center Factor In?

In a loaded forklift, the counterweight must offset the load on the forks.

Otherwise, the forklift will tip over.

But how would someone overload a forklift?

The most obvious answer is by simply adding more weight to the forks than the counterweight itself weighs.

This, of course, would be the same as trying to balance a 100 lb. person against a 200 lb. person on a seesaw.

But that’s not the only way to overload a forklift.

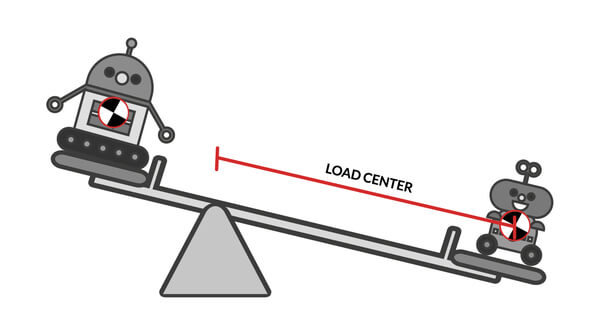

The other way is by increasing the distance between the load and the pivot point.

And that’s where the load center comes into play.

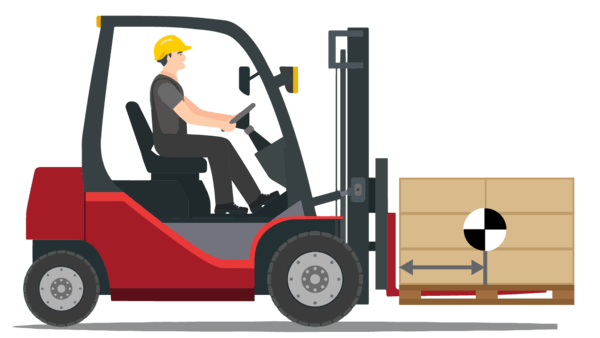

What Is the Load Center of a Forklift?

Which dimension defines the load center?

According to OSHA, it’s “…the distance from the face of the forks to the load’s center of gravity.”

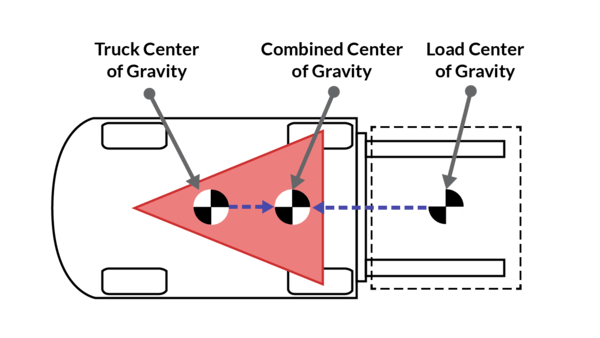

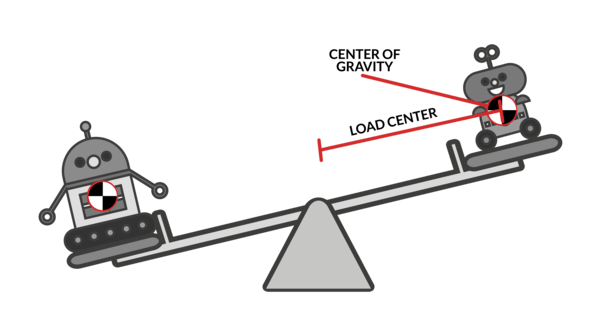

Now, this definition introduces the concept of the “forklift center of gravity.”

What does that mean?

The center of gravity is an imaginary point in an object where all of the object’s weight is concentrated.

In an unloaded forklift, the center of gravity is just below the operator’s seat.

And in an evenly-distributed load – say a pallet of bricks – the center of gravity is directly in the center.

And once the forklift has been loaded, the center of gravity does what?

Answer: It moves toward the pivot point of the forklift.

Let’s turn back to our seesaw example to see how load center and center of gravity work together.

Putting it All Together With the “Seesaw” Analogy

The first thing we need to address is the center of gravity of each rider.

When in a sitting position, the center of gravity of a person is in their chest area, directly above the hips.

So, let’s say the 200 lb. person is on one side of the seesaw.

And the 100 lb. person is on the other side – with each person an equal distance from the pivot point.

But say the 100 lb. person is able to move very far away from the pivot point.

At some point, the 100 lb. person will actually lift the 200 lb. person up in the air.

Why exactly?

Because the load center (that is, the distance to the center of gravity of the 100 lb. rider) increases.

And once it increases so much that the weight of the 200 lb. rider can’t offset it, the seesaw will tip down on the 100 lb. rider’s side.

This is what’s technically called the “load moment,” which is a measurement of the overturning force applied to one side.

And this is exactly what can happen with a forklift.

Put another way, if you load a forklift in such a way (for example, with an extra-long load) that the center of gravity of the load is farther away from the fork face than the truck’s load center rating allows, you can tip the forklift over.

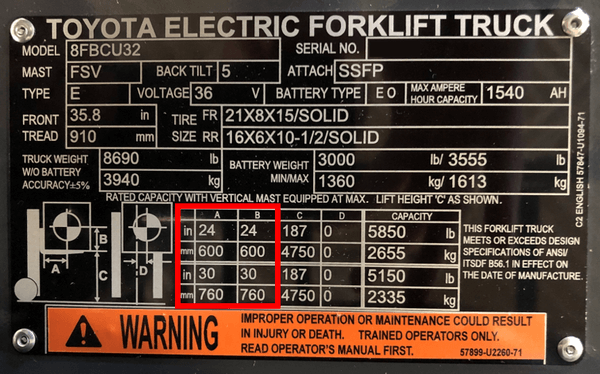

Where Can You Find the Load Center of Your Forklift?

Now that you understand what a forklift load center is, where can you find it?

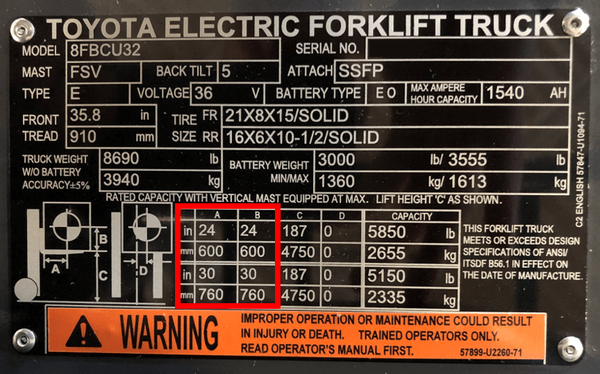

Answer: The forklift load center chart on your lift truck’s manufacturer-provided data plate.

That said, most forklifts are rated for a 24-inch load center.

The reason for this is that most pallets are 48 inches long.

And assuming the materials on the pallet are arranged evenly, the center of gravity of the load will be in the middle.

Given that the middle of a 48-inch pallet is at the 24-inch point, this is the reason why forklifts are rated at a 24-inch load center.

Is The Load Center Always 24 Inches?

No.

In fact, the load center can be anything.

After all, it’s simply a measurement of the distance between the center of gravity of the load and the fork face.

And depending on the design and use of the particular lift truck, the manufacturer may calculate the load center at different measurements.

For example, forklifts designed to lift long loads may be rated for 30- or even 60-inch load centers.

What Factors Can Increase the Load Center?

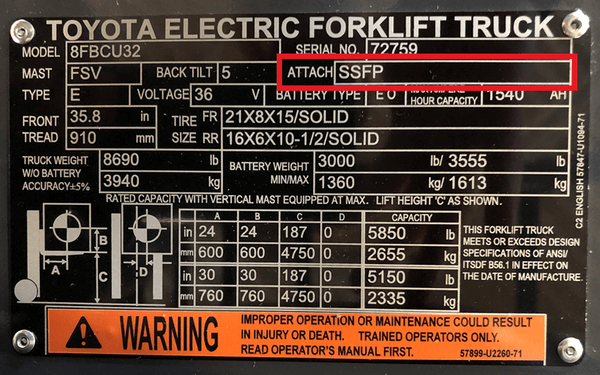

It’s important to understand that any installed attachments, such as sideshifters, fork positioners, and clamps, can increase the load center of a forklift.

Why is that so?

Because the thickness of a forklift attachment itself pushes the load out further than if there were just a pair of forks installed.

And in doing so, they increase the load moment (which as you may recall is the amount of overturning force applied to the forklift’s load end).

This is why any forklift with an attachment installed must have an updated data plate.

And the updated plate must list the attachment as well as provide a new load center and lifting capacity rating.

How to Calculate Lifting Capacities for Load Centers Other Than 24 Inches

**Before we get into calculating a load center safely and correctly, it’s IMPORTANT to ALWAYS obtain the legal capacity rating from the OEM manufacturer**

Why is knowing about a forklift’s load center so important?

Because it helps operators understand if they can lift any given load.

But depending on the load, this procedure can be easy or a bit challenging.

Let’s take an easy, and HYPOTHETICAL example first.

Say you’re operating a lift truck rated for 5,000 lbs. at a 24-inch load center.

And say that you’re looking to lift a 48-inch pallet weighing 5,000 lbs. that’s evenly loaded.

In this case, determining if your fork truck can lift it is pretty straightforward.

You simply look at the data plate and see what it says.

But in the real world, things don’t always work out so easily.

Instead, forklift operators often handle irregular loads where the center of gravity isn’t exactly in the center of the pallet.

Consequently, the load center will be different.

In these cases, how do you calculate the load capacity of a forklift?

Answer: By using the forklift load center calculator formula.

Here’s just one example calculation a OEM manufacturer may use:

Rated Load Center ÷ Actual Load Center x Rated Capacity of the Lift = Lifting Capacity

Not sure where to find these values?

You can find the rated load center on your fork truck’s data plate – usually 24-inches, as we’ve discussed.

You’ll need to determine where the center of gravity of the load you’re lifting is next.

Then, you’ll have to measure from there to the fork face to get the actual load center.

Finally, you’ll need to know the rated lifting capacity of your lift truck.

And you can find that by looking at the model number.

For example, a Toyota model 8FGCU25 forklift has a rated capacity of 5,000 lbs.

And this is based on the last two numbers in the model (25 = 2,500 kilograms = 5,000 lbs.).

Let’s go through a quick hypothetical example to see how this calculation may work by assuming the following values:

- Rated load center = 24 inches

- Actual load center = 36 inches

- Rated capacity = 5,000 lbs.

And here’s how we run the numbers:

- 24 ÷ 36 = 0.667

- 0.667 x 5000 = 3,333 lbs.

Thus, this means that our 5,000 lb.-rated forklift can actually lift 3,333 lbs. at a 36-inch load center.

**Again, it’s IMPORTANT to ALWAYS obtain the legal capacity rating from the OEM manufacturer and not make these calculations yourself**

6 Load Center Tips

Now that you know everything you need to about forklift load centers, here are a few tips to keep in mind as you operate your forklift:

-

Distribute your load evenly before lifting it.

Uneven loads can increase the load center and cause the forklift to tip over. Be sure to arrange the load evenly in both the vertical and horizontal directions to prevent the truck from tipping over on its side

-

Place loads on the forks as close to the load backrest as possible.

The further you place the load on the forks away from the load backrest, the more the load center increases. And this reduces the truck’s lifting capacity

-

Get a new data tag when installing an attachment.

Attachments add space to the distance between the fork face and the load. And this reduces the lifting capacity. When you add an attachment, contact your dealership for a new data tag. The new data tag should tell you how much weight the forklift can safely lift with the new attachment installed

-

Beware that tilting the mast forward reduces the load capacity.

Tilting the mast forward increases the load center. Why? Because you’re moving the load away from the pivot point (front axle). And when handling a load right at the truck’s capacity limit, tilting forward can cause the truck to tip forward

-

Beware when sideshifting a heavily-loaded forklift.

If you’re at the weight limit of your forklift, sideshifting can shift the sideways (horizontal) load center. If this happens, this can cause the forklift to become unstable laterally. And that can result in a sideways tip over

-

Drive carefully while carrying a load.

Even if the load is evenly distributed and within the nameplate’s guidelines, the truck can still become unstable. That’s why it’s important to accelerate and brake smoothly, slow down when taking turns, and keep the load low (4 to 6 inches) to the ground

Conclusion

There you have it: Everything you need to know about forklift load centers.