Wondering how high should a load be carried on a forklift?

Then you’re in the right place.

Because we’ll answer that question in this article, as well as address:

- How to safely prepare a forklift load

- How to properly lift a load

- The procedures for traveling with a loaded forklift

- How to deposit a load

- And much more!

Let’s dive in!

Quick Summary

Don’t have time to read the whole article? Here’s a quick summary of the main points:

- You should carry a load on a forklift 4 to 6 inches off the ground

- Carrying a load slightly off the ground helps improve stability, avoid hitting obstacles and pedestrians, and reduce fork wear

- You need to prepare your load before lifting it. This includes banding/wrapping any unsecured items and ensuring you’re not exceeding the weight capacity of your forklift

- You need to take proper precautions when lifting a load, including checking for overhead obstructions, ensuring your forks are level and spaced properly, and tilting back slightly to stabilize the load

- When traveling with a loaded forklift on even ground, ensure you watch out for obstacles and poor floor conditions, follow all traffic regulations, and look in the direction of travel

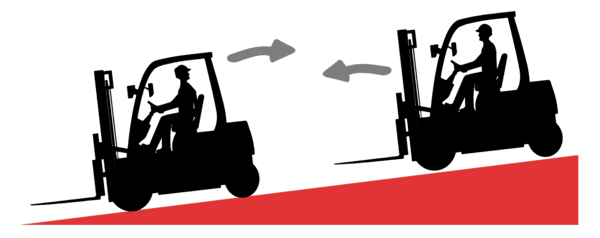

- Driving a loaded forklift on a ramp requires certain precautions, including ensuring you keep the load upgrade and always looking in the direction of travel

- Driving an unloaded forklift on a ramp requires separate precautions. This includes traveling with the forks downgrade and always looking in the direction of travel

- Lowering a load should include carefully approaching the deposit location, tilting the mast to a vertical position, and carefully lowering the load to deposit it

How High Should You Carry a Load on a Forklift?

Let’s answer this question immediately…

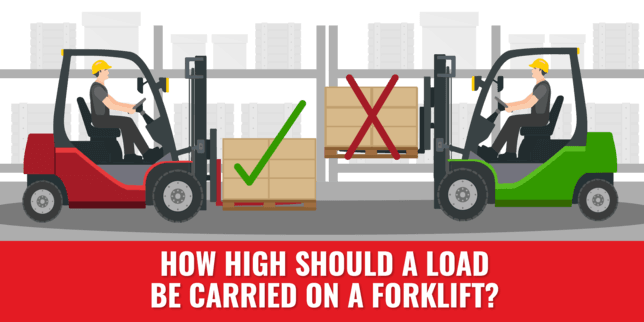

When traveling with a load, the load should be lifted 4 to 6 inches off the ground.

Why It’s Important to Carry a Load on Your Forks at a Certain Height

When using industrial forklifts, the load must be at the lowest position for traveling.

But why exactly?

We’ve covered this in a lot more detail in our Forklift Weight Capacity post.

But let’s briefly explain 3 key reasons why it’s important.

1. It Improves Stability

A forklift is less stable with a raised load because of the movement of the center of gravity.

Once the forklift has been loaded, the center of gravity does what?

It shifts forward towards the front axle and upwards toward the overhead guard.

The higher you raise the load, the more the center of gravity shifts.

And once it moves outside what’s called the “stability triangle,” you risk tipping the truck over.

So, keeping the load lower helps keep the center of gravity within the zone of stability.

2. It Helps Avoid Obstacles

For one, carrying your forklift load 4 to 6 inches off the ground helps to avoid hitting obstacles on the ground.

This includes expansion joints in concrete, uneven areas, slight slopes, debris, or even dock plates.

And for another, it helps reduce collisions with obstructions.

Examples include products, infrastructure, humans, and other lift trucks in the area.

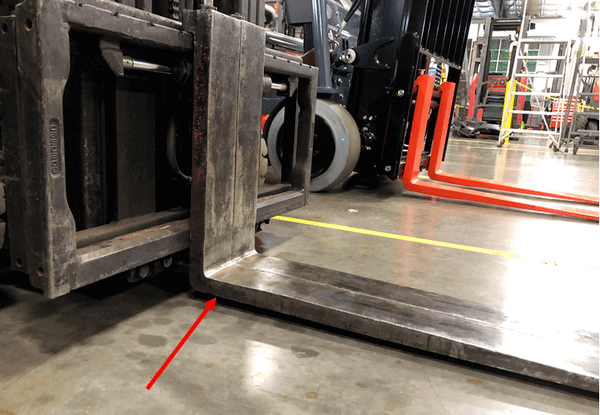

3. It Helps Avoids Excessive Fork Wear

If the forklift is unloaded, you still want to drive it with the forks off the ground.

This is so you don’t drag the forks, which can wear them out.

And wearing out your forklift’s forks decreases the lifting capacity, usually by around 20% for every 10% of fork wear.

Ultimately, this will prove costly since you’ll have to replace the forks more frequently.

How to Safely Operate a Forklift: Preparing, Lifting, Traveling, and Lowering Loads

The topic of this article is: “How high should you carry a load on a forklift?”

But this is really part of a wider discussion of how to properly operate a forklift.

This includes topics like:

-

Preparing forklift loads

-

Lifting loads

-

Traveling with loads

-

Lowering loads

Let’s go through the risks and procedures for each of these activities.

Preparing a Load Before Lifting It: What You Need to Know

Properly preparing a load before lifting is crucial for preventing hazards and improving safety.

The Risks of Unprepared Loads

If you don’t properly prepare loads before lifting them, you run many risks, including:

-

Tip-overs. Uneven loads can affect the forklift’s stability and cause it to overturn

-

Injury to pedestrians. Unsecured loads can fall and strike pedestrians

-

Damage to product and infrastructure. A falling load can also damage the product itself. Furthermore, it can cause damage to equipment and infrastructure like pallet racking

How to Properly Prepare a Load

OSHA recommends the following practices for preparing a load:

-

Safely arrange and secure the load. Do not carry loose products – use banding or wrapping to secure them

-

Center the load. If handling an off-center load that cannot be centered, load the forklift with the heaviest side of the load near the front axle

-

Do not overload. Refer to your forklift’s nameplate for the rated capacity and never exceed it

-

Abide by the rated load center. Your forklift’s nameplate will also show the rated load center. Even if the load is within the rated weight capacity, exceeding the specified load center can unbalance the forklift

Is a Load Backrest Required on a Forklift?

OSHA says that if the load can fall on the operator, the forklift needs a load backrest.

But if the load doesn’t present a danger to the operator, you don’t need one.

Lifting a Load: What You Need to Know

Once you’ve properly prepared your load, you’re ready to lift it.

But not before understanding exactly how to properly and safely do so.

The Risks of Lifting a Load With a Forklift

What should you check before lifting a load? The following:

-

Clearance for overhead obstructions. Be careful not to strike or get your load caught on sprinkler systems, overhead doors, or in pallet racking while lifting

-

Load stability. You should’ve already secured any loose items in your load. But also make sure that the load itself is secure on the forks or attachment so it doesn’t fall off

How to Safely Lift a Forklift Load

OSHA’s recommended practices and requirements when lifting loads with a forklift are:

-

Ensure your forks are level. Before inserting them into a pallet, ensure your forks are at a 90° angle

-

Space your forks properly. When picking up a load, the forks should be inserted at least 2/3 of the load length. How far apart should forks be spaced? Adjust the forks as wide as possible to provide a more even weight distribution

-

Check the headroom. Ensure adequate overhead clearance, especially when in a confined space or using a high-lifting truck

-

Lift to the proper height. Lift the load slightly above the lower stack to around 4 inches

-

Tilt back slightly. When picking up a load, it should be tilted back slightly to allow the load to rest against the load backrest

A Few More Words On How To Lift A Load…

How to Tell If Your Forks Are Level

How do you know forks are level on a forklift?

The easiest way to tell is to use a forklift with a built-in fork leveling mechanism.

For example, take Toyota forklifts.

All you need to do to level the forks is press a button on the tilt lever while tilting the mast and it will automatically stop once it’s at 90°.

If your forklift doesn’t have this feature, there are forklift mast angle gauges that you can buy.

These use a small gauge to show you the mast tilt degree.

So, if you need to level the mast to 90°, you simply look at the gauge and move the mast until it shows 90°.

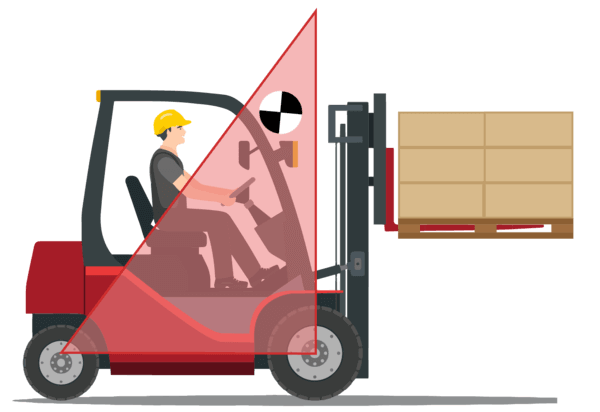

Why Is it Important to Tilt the Mast When Picking up a Load on a Forklift?

You may be wondering: Why do you have to tilt the mast?

Here’s the short answer…

When picking up a load the forks should be tilted to stabilize the load.

This is because, when you tilt the mast backward, you’re moving the combined center of gravity further within the forklift’s stability zone.

Why Must You Use Extra Caution When Tilting the Mast Forward?

Tilting a forklift mast forward moves the combined center of gravity closer to or even outside of the stability triangle.

And this can result in tipping the forklift over.

Thus, you should never travel with the load in a forward-tilted position.

Instead, you should only tilt the mast forward when depositing a load and always use extreme caution with any mast movements.

Traveling With a Loaded Forklift on Even Ground: What You Need to Know

Once you’ve lifted the load, you’ll need to travel with it to your destination.

But, there are risks when traveling with a load on a forklift.

The Risks of Traveling With a Loaded Forklift on Even Ground

When traveling with a loaded forklift, you need to be aware of:

-

Tip-overs. Overturning can happen when taking sharp corners, driving too fast, or driving with the load too high

-

Collisions with obstacles and pedestrians. This can happen if the operator isn’t paying close enough attention to the travel surface or is traveling too fast and can’t stop in time

-

Falling loads. Excessive speed or inattentive driving can cause the load to come off the forks and injure pedestrians or damage infrastructure

How to Safely Travel With a Loaded Forklift on Even Ground

OSHA’s recommended practices and requirements for safe travel with a loaded forklift on level ground are:

-

Observe your surroundings. Before moving, look in all directions to confirm no obstructions above, below, or sideways

-

Look in the direction of travel. If the load is blocking your view, it’s recommended to travel in reverse to keep a clear view

-

Observe traffic regulations. This includes speed limits, maintaining a safe distance, and being cautious at intersections and blind spots

-

Secure anything movable before you drive over it. Properly secure bridge plates and dockboards before driving over them. And never exceed their rated weight capacity

Why Do You Tilt The Load Back When Traveling?

For 2 reasons:

- To help stabilize the forklift

- To help prevent the load from sliding off

Traveling With a Forklift on a Ramp: What You Need to Know

You now know the risks and precautions to take when driving a loaded forklift on even ground.

But there are special considerations when driving a forklift on uneven ground, such as ramps, inclines, and slopes.

In general, you must take the following precautions when working with a lift truck on a slope:

-

Look in the direction of travel at all times

-

Don’t turn on an incline – do so before reaching it

-

Stay as far away from the edge of the incline as possible

-

Check your fork truck’s gradeability rating before attempting to traverse an incline

Here’s what else you need to know.

The Risks of Traveling With a Forklift on a Ramp

When traveling on a ramp on a forklift, the dangers include:

-

Tip-overs. Turning while on a slope or even a slight incline can cause the forklift to tip over

-

Falling loads. Traversing an incline in the wrong direction can cause the load to come off the forks and strike pedestrians or infrastructure

How Should a Loaded Lift Truck Be Driven on a Ramp?

You should always drive a loaded lift truck with the load pointing upgrade.

That means when going up the slope, you should drive forward with the load pointed up the slope.

When traveling down a ramp or incline on a forklift, you should drive backward with the load pointed up the slope.

Additionally, you should look down the slope (i.e. behind you) when reversing down a slope.

How Should You Drive an Unloaded Lift Truck on a Ramp?

You should always drive an unloaded lift truck with the forks pointing downgrade.

This means when traveling up a ramp without a load, you should drive backward with the forks pointed down the slope and look in the travel direction.

When going down the slope, drive forward with the forks pointed down the slope.

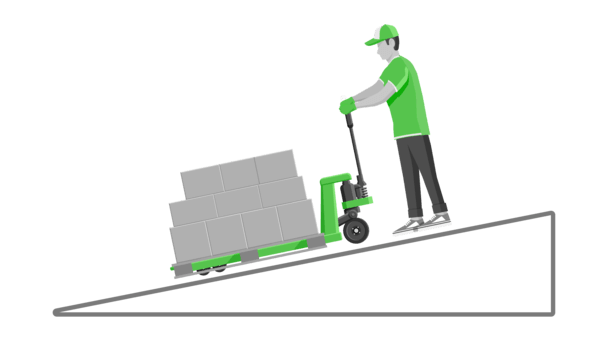

Using a Pallet Jack on a Ramp: What You Need to Know

When using a pallet jack on a ramp, you should travel with the forks pointed down the incline.

That’s regardless of which direction you’re traveling and whether or not you have a load.

Otherwise, you can have a runaway pallet jack that could crash into your or someone else.

Lowering a Load: What You Need to Know

You’re at your destination and ready to deposit the load.

How do you do it?

First, you’ll need to be aware of the risks involved with lowering the load.

Lowering a Load: The Risks

While lowering a forklift load, potential hazards include:

-

Falling loads. Lowering improperly can cause the load to fall off the forks

-

Crushing pedestrians. Lowering a load without paying close enough attention can crush nearby workers

How to Safely Lower a Load on a Forklift

OSHA’s procedures for lowering a forklift load are:

-

Ensure the mast is tilted slightly backward. Carefully tilt the forklift’s mast to a backward position to stabilize the load

-

Move toward the stack. Drive your lift truck 8 to 12 inches away from the stack

-

Return the mast to the vertical position. Before lowing, tilt the mast until it’s 90° vertical

-

Lower the load. 6 to 8 inches above the floor to ensure proper positioning

-

Deposit the load. Fully lower the forks until the load is resting in the deposit position

Conclusion

There you have it: Everything you need to know about how high to carry a load on a forklift.