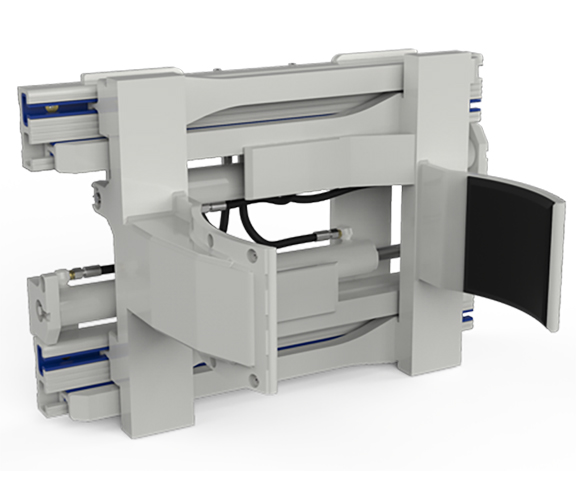

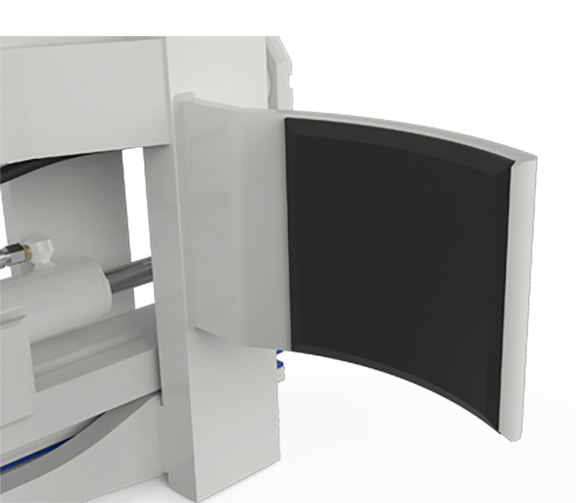

The Cascade J-Series Drum Clamps are designed for efficient handling in industries like petroleum and chemicals, where moving standard 55-gallon drums is essential. Built to streamline operations, these drum clamps increase productivity by enabling the transport of up to four drums per load, reducing handling time and improving workflow.

Ideal for demanding applications, they provide a secure grip and smooth performance, ensuring both safety and efficiency in drum handling tasks.

Model Numbers: 25D-DTB | 35D-DTB | 25D-DTS | 35D-DTS | 35D-DTR | 25D-DFB | 35D-DFB | 25D-DFS | 35D-DFS | 35D-DFR | 14J-DTB-2A | 18J-DTB-2A | 14J-DTS-2A | 18J-DTS-2A | 14J-DTR-2A | 18J-DTR-2A | 14J-DFB-2A | 18J-DFB-2A | 14J-DFS-2A | 18J-DFS-2A | 14J-DFR-2A | 18J-DFR-2A