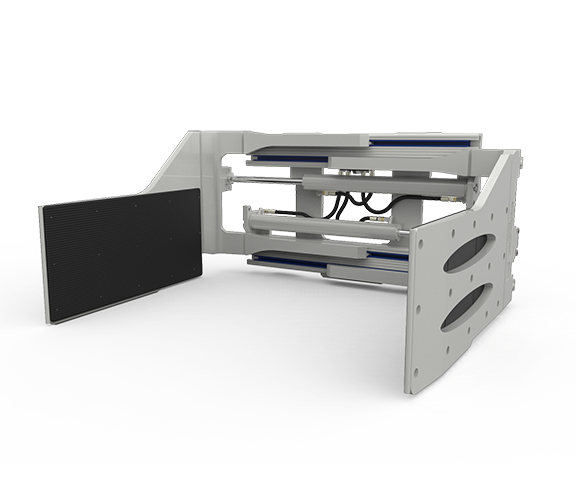

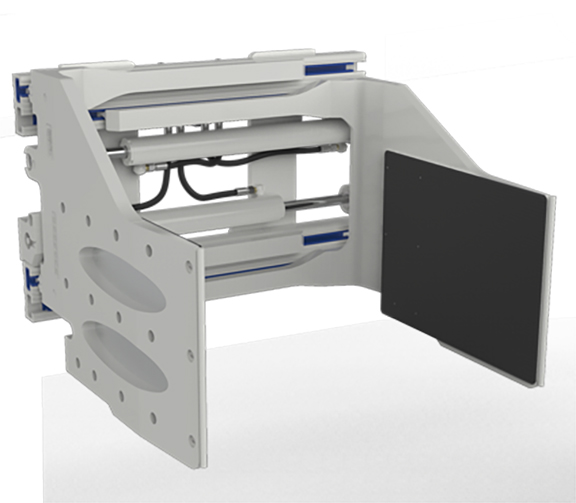

Model Numbers: 14J-MCB-2A | 18J-MCB-2A | 22J-MCB-2A | 22J-MCB-3A | 26J-MCB-3A | 14J-MCS-2A | 18J-MCS-2A | 22J-MCS-2A | 22J-MCS-3A | 26J-MCS-3A | 18J-MCR-2A | 22J-MCR-2A | 22J-MCR-3A | 26J-MCR-3A | 25D-MCB | 35D-MCB | 50D-MCB | 70D-MCB | 25D-MCS | 35D-MCS | 50D-MCS | 70D-MCS | 35D-MCR | 50D-MCR | 70D-MCR

Cascade J-Series Multi-Purpose Clamps

- 2,500 – 7,000 lb. Capacity

- II – III Mounting Class

- 20.2 – 77.7 in. Opening Range

- 29.6 – 45.6 in. Arm Length

Documents

Product Documents

Videos

Attachment Resources

The Cascade J-Series Multi-Purpose Clamps are designed for efficient, economical handling of diverse load types, including corrugated, metal, and wooden containers as well as baled products. By reducing or eliminating the need for pallets, these clamps help cut costs tied to pallet purchase, rental, maintenance, disposal, and storage. With the ability to build loads to order or skim partial loads, the J-Series Multi-Purpose Clamps offer flexibility and efficiency, making them an ideal solution for a variety of material handling needs.

D-Series Features

- Proven, durable arm and aluminum frame construction ensuring long useful life of the clamp

- Superior arm-slide material and design for extended bearing life

- Low profile frame for visibility over the clamp

- Thin arm profiles for handling in between tightly spaced loads

- Regenerative hydraulic valving for optimal arm speed

- Replaceable aluminum pads with ribbed rubber facing

J-Series Features

- Industry-leading visibility

- Efficient hydraulic system which minimizes energy consumption and maximizes performance

- Clamp and backhand protection

- Flow divider for equal arm movement

- Top-mounted hydraulic cartridges and test port for ease of access and adjustment

- Sideshift circuit relief optimizes sideshift speed and performance

- Rugged design for optimal strength, durability and performance

- Center mounted hardened replaceable frame wear segment (Except for revolving models)

- High strength steel frame

- Lubrication-free, full length UHMW bearings

- High strength steel castings

- Maximum clamp force for secure handling

- Designed for convenience and performance

- Integrated true centering key for precise and secure installation

- Available in two pressure offerings to match attachment to truck hydraulic system

- Integral welded arm casting for added strength or bolt-on arm offering for added flexibility

- Ribbed rubber faced contact pads for secure load handling

- No maintenance bearings with 10,000 hour warranty

- Rubber faced contact pad ensures a secure grip

- True centering key for precise and secure mounting

- Standard adjustable pressure relief in clamp and sideshift functions

- Industry leading visibility through frame

D-Series Options

- Custom opening ranges

- Custom arm sizes

- Custom arm surfaces

- Various mounting classes available

- Quick-change lower hooks

- Load backrests

J-Series Options

- Special frame widths and opening ranges

- High and Low pressure hydraulics systems available

- Basic, sideshifting and revolving (360°) models

- Independent arm control

- Regeneration valve (faster opening speed for low flow electric trucks). For electric trucks or those with low flow hydraulics. External sideshifter available

- Valve guard

- Factory installed load backrest

- Bumper/Cylinder cover

- Quick Disconnect Mounting Kit

- Recycling & Waste Management

- Manufacturing

- Construction

- Warehousing & Logistics