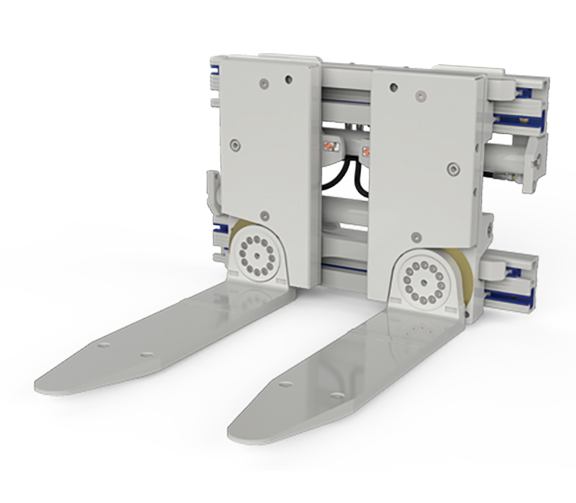

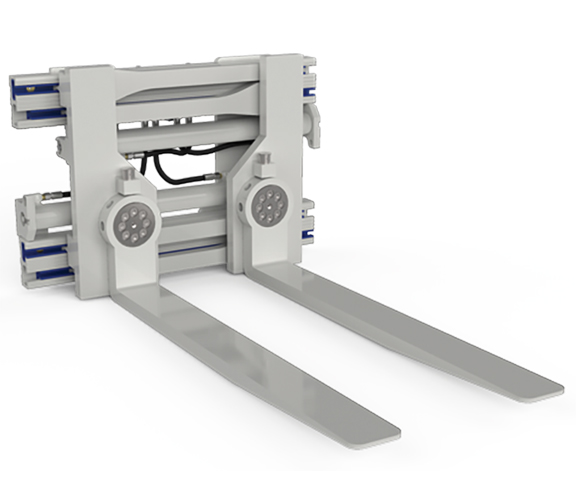

The Cascade TURNAFORK™ is a versatile solution for manufacturing, warehousing, and shipping environments that require both clamp and pallet handling. With arms that rotate vertically for clamping and horizontally for traditional pallet handling, the TURNAFORK™ adapts to varied tasks with ease. Ideal for handling cartons and awkward loads like large tires, it also simplifies order picking by efficiently managing layers of mixed products onto pallets. Built for flexibility and efficiency, the TURNAFORK™ is the perfect choice for streamlining operations in dynamic material handling settings.

Model Numbers: 40D-CTS | 22J-CTS-2A | 22J-CTS-3A | 22J-HTS-2A | 22J-HTS-3A