Whether you’re a safety manager, operator, or equipment purchaser, understanding the different types of mobile elevating work platforms (MEWPs) is essential for choosing the right lift for the job—and using it safely.

Formerly known as aerial work platforms (AWPs), MEWPs are now classified under a new system introduced by the American National Standards Institute (ANSI), which affects everything from equipment design to operator training requirements.

In this complete guide, we’ll walk you through the types of MEWPS, explain what the new ANSI standards mean, and help you identify the right type of lift for your application—whether it’s a scissor lift, boom lift, or vertical mast lifts.

Let’s dive in!

Quick Summary

Don’t have time to read the whole article? Here’s a quick summary of the main points:

- ANSI changed the rules on aerial lifts in 2020

- Aerial lifts are now called MEWPs, which stands for “mobile elevating work platforms”

- MEWPs are now classified according to Group and Type

- There are Group A and Group B MEWPs, as well as Types 1, 2, and 3

- The new ANSI standards have also changed rules on MEWP safety planning, training, and design

- All operators must now be trained according to the new ANSI standards in order to be certified to operate a MEWP

The New ANSI Standards for Aerial Lifts: What You Need to Know

What Is ANSI?

“ANSI” stands for the American National Standards Institute. It is a private, non-profit organization that develops design and usage standards for many industries, including standards for aerial lift equipment.

Now, the purpose of this article is to make you familiar with the new ANSI standards for aerial lifts.

So let’s go through some frequently asked questions about ANSI to start.

When Was the Last Update to the ANSI Aerial Lift Standards?

ANSI began developing the new MEWP standards around 2017–2018, with the standards approved and published in December 2018. They were originally slated to take effect in December 2019, but after some delays and appeals, the new standards ultimately became effective in 2020. All aerial lift manufacturers were given up to one year from the effective date to bring new machines into compliance.

Why Did ANSI Update the Aerial Lift Standards?

They were updated for several key reasons:

- Increase safety – by improving safe-use practices and expanding training requirements

- Modernize equipment design – adding modern safety features to MEWPs

- Simplify classifications – introducing a clearer grouping & typing system, and clarifying maintenance responsibilities

- Align globally – harmonizing U.S. standards with international norms

What Do the New ANSI Rules Cover?

The new ANSI rules replace the prior ANSI A92.3, A92.5, A92.6 (and related) standards for aerial work platforms. They introduce a suite of three standards, each addressing a different aspect of MEWPs:

- ANSI A92.20 – covering equipment design and construction requirements for MEWPs.

- ANSI A92.22 – covering the safe use of MEWPs (job site procedures, risk assessments, etc.)

- ANSI A92.24 – covering training requirements for MEWP operation.

Together, these new standards define responsibilities for manufacturers, owners, dealers, users, and operators of MEWPs. In essence, they provide comprehensive guidelines on everything from how machines must be built and tested, to how they should be used in the field and how personnel must be trained.

What Is a MEWP?

One of the key changes to the ANSI aerial lift standards is the terminology. Previously, an “aerial work platform (AWP)” referred to scissor lifts, boom lifts, and similar elevated work platforms. Now, the official term is mobile elevating work platform (MEWP). The word “mobile” indicates the equipment can be moved either under its own power or manually. Essentially, MEWP is a broad category that includes scissor lifts, boom lifts, vertical mast lifts, and other devices that elevate workers.

In practice, if a machine can lift people to height and is mobile (can be driven or rolled), it is considered a MEWP under the new standards.

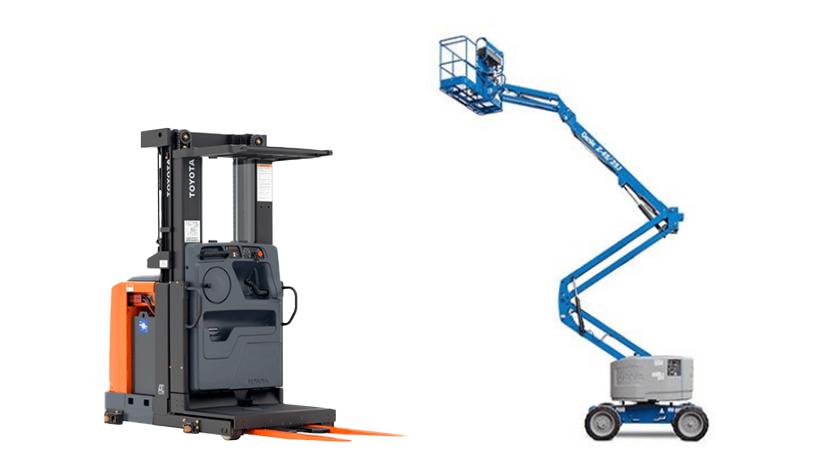

Is a Cherry Picker a MEWP?

Yes – a “cherry picker” is a common nickname for certain boom lifts (or even for an order-picker forklift), and these are considered types of MEWPs. For example, an articulating boom lift with a bucket is often called a cherry picker, and it falls under the MEWP classifications. An order picker (a type of lift truck where the operator is lifted with the load) also qualifies as a MEWP under the new system.

In short, any mobile device that elevates personnel – whether it’s a boom-type Genie lift or a mast-style Toyota order picker – is regarded as a MEWP (though different machines fall into different groups and types, explained next).

MEWP Classifications: What Are the Different Types?

Under the previous AWP standards, aerial lifts were categorized by names like “scissor lift” or “boom lift.” Now, the ANSI A92.20 standard introduces a classification system for MEWPs based on Group and Type. Every MEWP is classified in two ways:

- Group: determined by the platform’s ability to extend beyond the machine’s tipping line (i.e. beyond its wheelbase or outriggers)

- Type: determined by whether the machine can travel while the platform is elevated, and where the travel controls are located

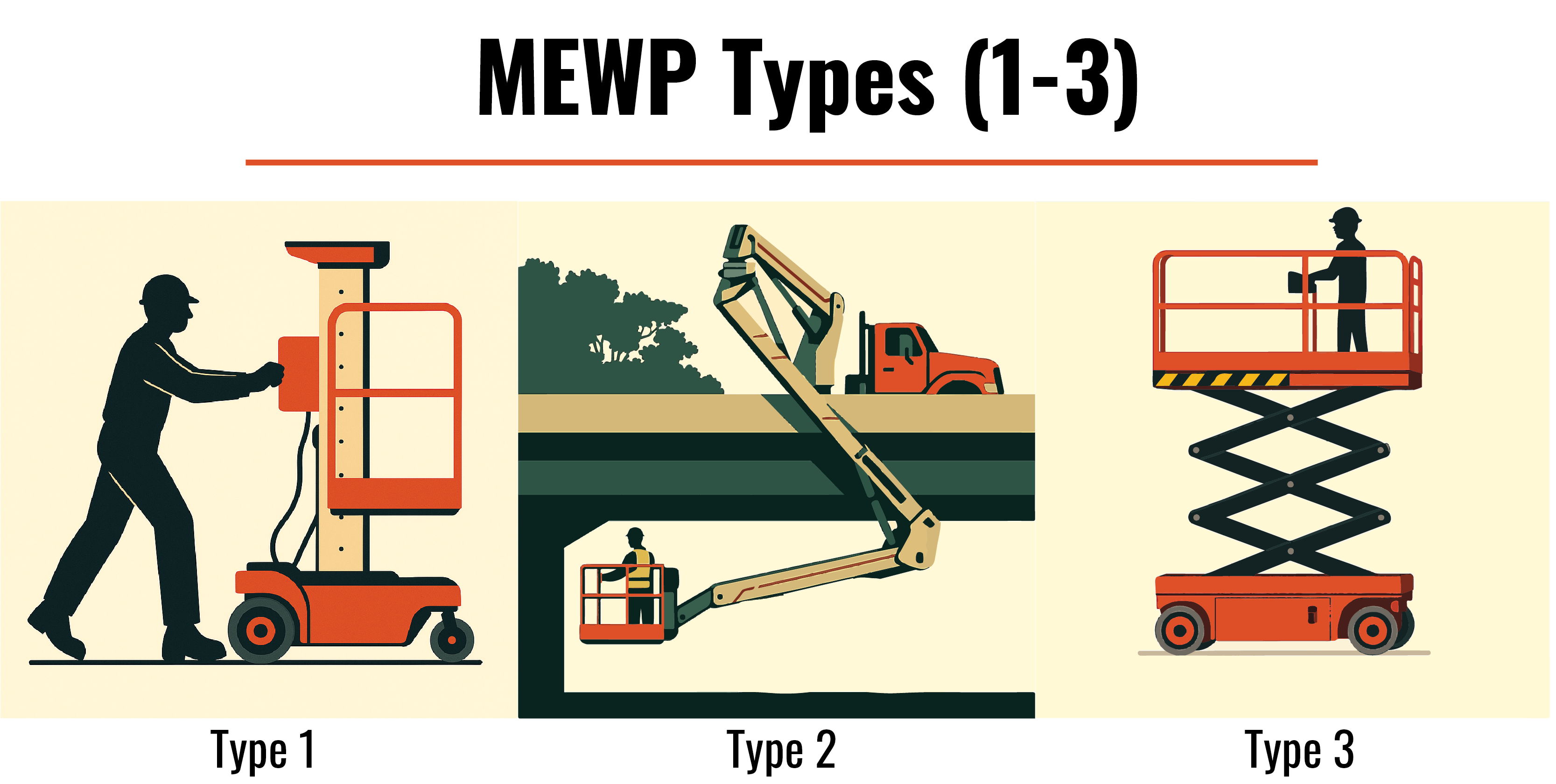

In total, there are two groups (Group A and Group B) and three types (Type 1, 2, and 3). Any MEWP’s full classification is a combination of its Group and Type (for example, “Group B, Type 3”).

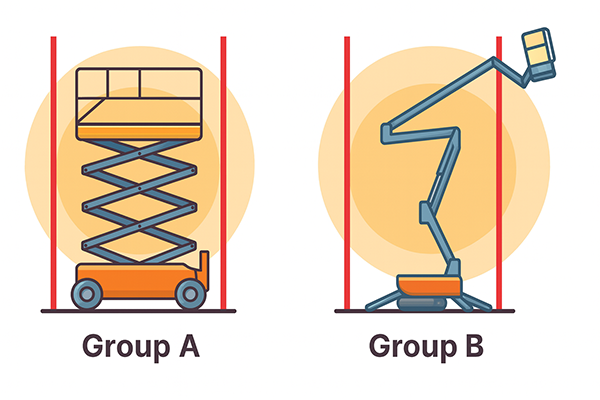

MEWP Classification By Group

A MEWP’s group is based on the platform location relative to the tipping lines of the machine. The tipping lines are the boundaries defined by the machine’s wheels or outriggers (the supports that contact the ground). If the platform stays within those boundaries at all times, the MEWP is Group A. If the platform can extend beyond those boundaries at any point, it is Group B.

Group A

MEWPs with platforms that move only vertically and always stay inside the tipping lines of the chassis. In other words, the platform remains within the machine’s base footprint at all heights.

Standard scissor lifts and vertical mast lifts are examples of Group A – their platforms go straight up and down, directly above the base.

Group B

MEWPs with platforms that can extend beyond the tipping lines of the chassis. This category includes any boom-type lift where the platform can swing out or telescope out past the vehicle’s footprint.

Articulating and telescopic boom lifts (a.k.a. cherry pickers) are Group B machines, since their booms allow the basket to move outside the base area.

Table 1: MEWP Groups and Examples

| Group | Definition | Examples |

|---|---|---|

| Group A | Platform only moves vertically and stays within the machine’s base (inside tipping lines) | Scissor lifts, Vertical mast lifts |

| Group B | Platform can operate beyond the machine’s chassis or outriggers (beyond tipping lines) | Boom lifts (articulating or telescopic), Bridge inspection units |

MEWPs Classification By Type

The type classification of a MEWP is based on how (and whether) the machine can travel when the platform is elevated, as well as where the travel controls are located.

There are three types:

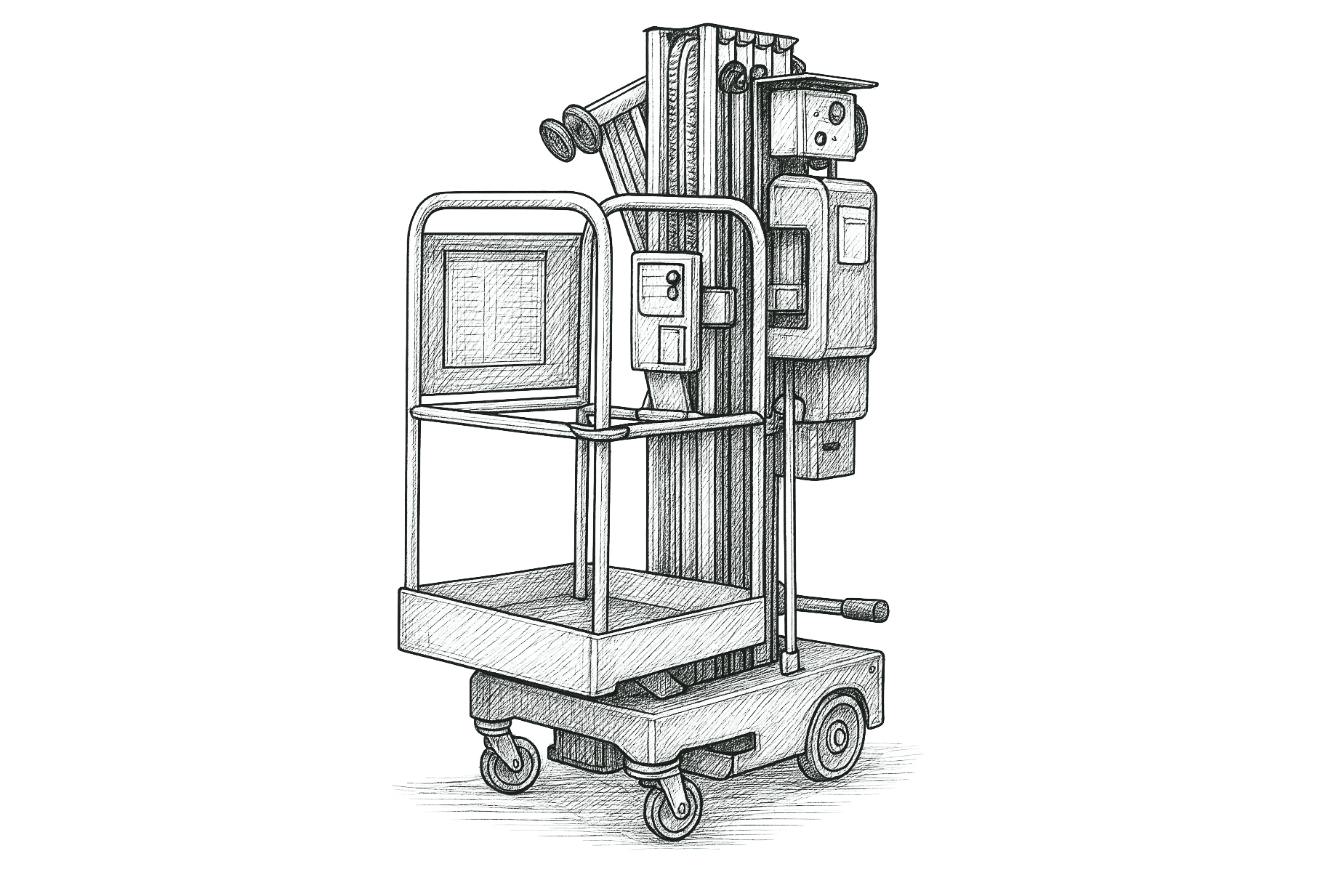

Type 1 MEWP

The MEWP can only be moved when the platform is in its stowed (fully lowered) position. It cannot be driven or repositioned while elevated.

(Example: a push-around vertical lift must be lowered and manually pushed or towed to a new location.)

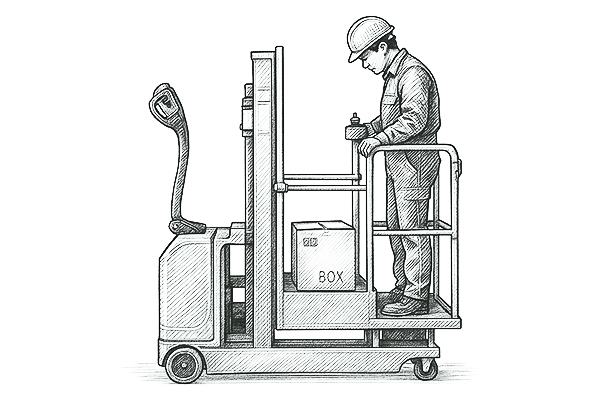

Type 2 MEWP

The MEWP can be moved while the platform is elevated, but the travel controls are located on the chassis (i.e. controlled from the ground).

An example would be a truck-mounted aerial lift where an operator on the ground controls movement, or certain under-bridge inspection machines.

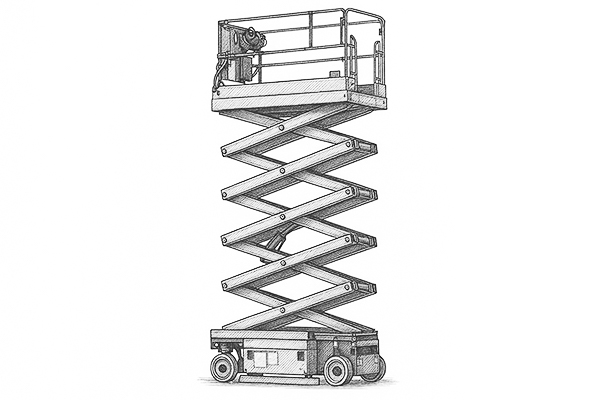

Type 3 MEWP

The MEWP can be moved while the platform is elevated, and the travel controls are on the platform (i.e. controlled from the basket).

Most self-propelled lifts – like typical JLG scissor lifts and boom lifts – are Type 3, since the operator in the platform can drive the machine while it is raised.

Table 2: MEWP Types and Examples

| Type | Travel Capability | Examples |

|---|---|---|

| Type 1 | Can only be driven when fully lowered (no travel with platform raised) | Push-around vertical lifts; trailer-mounted boom lifts (towed into place) |

| Type 2 | Can travel with platform elevated; controls are on the chassis (ground controls) | Vehicle-mounted bucket lifts (controlled from ground); under-bridge inspection units |

| Type 3 | Can travel with platform elevated; controls are on the platform | Self-propelled scissor lifts and boom lifts (controlled from the platform) |

Every MEWP is identified by a combination of Group and Type. For example, a standard electric scissor lift is a Group A, Type 3 MEWP (often abbreviated “3A”). A large boom lift that you drive from the platform would be a Group B, Type 3 (“3B”) MEWP. There are six possible Group/Type combinations (1A, 2A, 3A, 1B, 2B, 3B), and each corresponds to particular kinds of equipment.

Examples of MEWPs

To make the classification system clearer, here are examples of each Group/Type combination of MEWP:

Group A, Type 1

A Genie AWP-30 push-around vertical lift is an example of a Group A, Type 1 MEWP – its platform stays within the base footprint and the lift can only be moved when fully lowered.

Group A, Type 2

A walkie stacker forklift with a personnel platform attachment is an example of a Group A, Type 2 MEWP – the platform lifts vertically inside the chassis, and the unit can travel when elevated but only using ground controls.

Group A, Type 3

A standard electric scissor lift (for instance, a 19-foot slab scissor lift) is a Group A, Type 3 MEWP – its platform stays over the chassis and the operator can drive the machine from the platform while elevated.

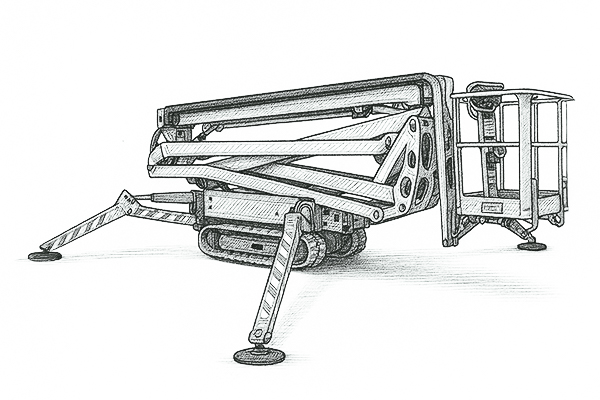

Group B, Type 1

A trailer-mounted boom lift with outriggers is an example of a Group B, Type 1 MEWP – its platform extends beyond the base, but the machine cannot be driven when the boom is raised.

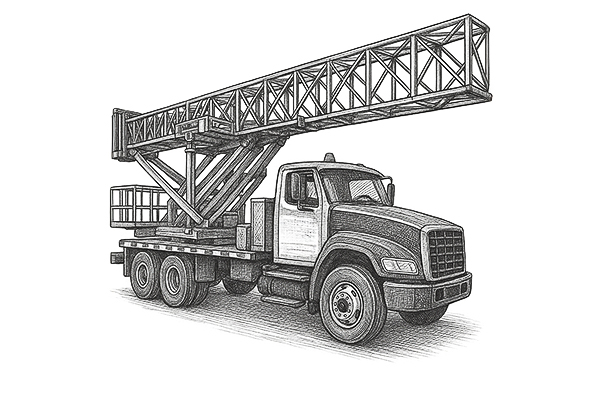

Group B, Type 2

An under-bridge inspection unit is a typical Group B, Type 2 MEWP – its platform reaches beyond the base structure, and an operator on the ground controls the movement when the platform is extended.

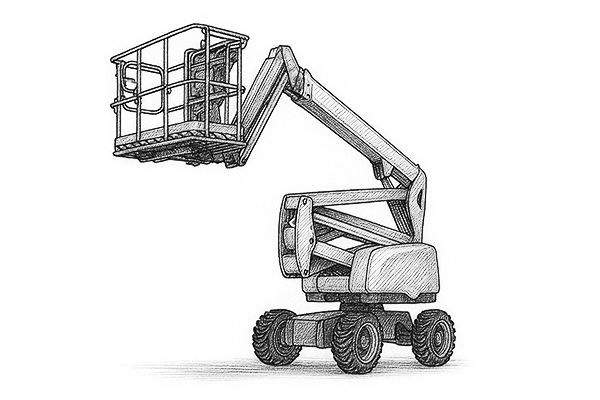

Group B, Type 3

A self-propelled articulating boom lift (like a Genie Z-45) is a Group B, Type 3 MEWP – the boom lets the platform extend past the chassis, and the operator can drive the machine from the basket while elevated.

Other Things You Should Know About the New ANSI MEWP Rules

Beyond the name change and new classification system, the updated ANSI A92 standards introduced several other important requirements. These fall into a few key areas:

- Safety planning – conducting thorough job-site risk assessments and having rescue plans in place

- Training – expanding training requirements to cover not just operators but also occupants, supervisors, and maintenance personnel

- Design changes – new safety features and design standards for MEWP equipment manufactured after the rule changes

Let’s look at the highlights of each of these areas.

Safety Planning: Risk Assessment and Rescue Plans

Under the new ANSI A92.22 safe-use standard, users of MEWPs must develop a Safe Use Program specific to MEWP operations. A central part of this is performing a pre-job risk assessment of the work site and task. In plain terms, before operating a MEWP, a qualified person should survey the area and identify any hazards or unsafe conditions.

Some basic requirements for MEWP safe use planning include:

- Assessing the work site for hazards (e.g. drop-offs, slopes, overhead power lines, unstable ground, weather conditions) and taking steps to eliminate or mitigate those hazards

- Selecting the proper MEWP for the job and ensuring the ground or floor can support its weight

- Defining safe work procedures and communication methods for the task

- Assigning a trained and qualified supervisor to monitor the MEWP operation and ensure compliance with safety rules

- Preventing unauthorized use of the MEWP (restricting access to equipment)

- Ensuring the safety of anyone on the ground near the MEWP operation (keeping bystanders clear)

- Properly documenting the risk assessment, rescue plan, and training, and retaining those records

After identifying the hazards and planned control measures, a written work plan or procedure should be created and communicated to all personnel involved

Along with risk assessment, the standards require having a rescue plan in place for MEWP operations. Since MEWPs involve working at height, there is a risk of a worker becoming stuck in the platform or even experiencing a fall while wearing a harness. The rescue plan outlines how to retrieve people safely if the MEWP cannot be lowered normally or if an accident occurs.

The rescue plan should aim to limit the time any worker spends suspended in a harness after a fall. All occupants on the platform must be trained on the rescue procedures to follow if they or someone else falls or is stranded. The plan should address three levels of rescue methods:

- Self-rescue: The operator (or person in the platform) uses the MEWP’s controls or emergency systems to bring themselves down.

- Assisted rescue: Another person at the site uses ground controls or another MEWP to help lower the platform or retrieve the worker.

- Technical rescue: Emergency services (e.g. fire department high-angle rescue team) are called in to perform the rescue if the situation is beyond the site’s capabilities.

The rescue plan must be documented and incorporated into the company’s procedures and training. That way, if something goes wrong, everyone knows beforehand how to respond quickly and safely.

Training Requirements for MEWP Operators and Other Personnel

One of the biggest changes in the new ANSI standards is expanded training requirements. In the past, the focus was mainly on operator training. Now, ANSI A92.24 requires that operators, occupants, supervisors, and maintenance technicians all receive appropriate training related to MEWPs.

Operators: Anyone who operates a MEWP must be trained under the new standards – even if they were previously certified under the old rules. The training is now MEWP-specific, meaning an operator is only qualified to run the particular Group and Type of MEWP they were trained on. (For example, being trained only on a Group A scissor lift doesn’t qualify an operator to use a Group B boom lift.)

Operator training must cover topics including MEWP terminology, the responsibilities of all parties, how to identify and avoid safety hazards, and proper operating procedure. It also must include hands-on practical training and evaluation of the operator’s skill.

Occupants: An “occupant” is anyone in the MEWP platform who is not the primary operator (for instance, a coworker riding in the basket). Under the new standards, occupants require a basic level of knowledge to work safely. They don’t need full operator certification, but the operator must inform them of at least the following:

- How to use fall protection properly on the MEWP, including knowing the location of anchorage points.

- How to operate the MEWP’s controls in an emergency, if the operator is unable to do so.

- The fundamental safety rules for MEWP use (e.g. not leaning out of the platform, not exceeding capacity.)

- How their actions (like sudden movements or leaning) can affect the machine’s stability.

- Any site-specific hazards or warnings related to the MEWP operation, and how to avoid those hazards.

In short, every person on the platform needs to be oriented on MEWP safety so they don’t inadvertently put themselves or others at risk.

Supervisors: Anyone supervising MEWP operators must also be trained under the new rules. The supervisor training should ensure they understand how to select the correct MEWP for a given task and the key safety rules and standards that operators must follow. Supervisors should be able to recognize potential hazards associated with MEWP operations and verify that operators under their watch are following the proper safety procedures. Essentially, the supervisor needs to be knowledgeable enough to be an effective safety overseer for MEWP use.

Maintenance Technicians: The new standards even extend to those who inspect or repair MEWPs. Maintenance and repair personnel must be trained by a qualified person to properly maintain the equipment in accordance with the manufacturer’s recommendations and the ANSI/CSA standards. The standards also specify required inspection intervals: a frequent inspection when a MEWP is first put into service or has been out of service for more than 3 months, and an annual inspection at least every 13 months. Maintenance staff must be trained to carry out these inspections and keep the machine in safe working order.

Overall, the emphasis is that everyone involved with MEWP operations – from the workers in the platform to those supervising and those servicing the equipment – needs some level of training and familiarization. This holistic approach aims to eliminate knowledge gaps that could lead to accidents, by making sure all parties understand their role in safe MEWP use.

Check out Conger’s OSHA-compliant MEWP operator safety training course

Conger offers an OSHA-compliant MEWP Operator Safety Training course that covers all these topics and is fully up-to-date with the new ANSI A92 standards.

New MEWP Design Requirements

The ANSI A92.20 standard (which deals with MEWP design) imposed several new design and safety feature requirements on manufacturers. These apply to newly manufactured MEWPs (machines made after the standards took effect). Existing machines in the field don’t need to be retrofitted, but any new models must incorporate these changes. Here are some of the key design updates:

Platform Load Sensing

New MEWPs are required to have an active platform load sensing system. This means the machine continuously monitors the weight on the platform. If the load exceeds the platform’s rated capacity, the system will trigger an alarm and disable further elevating or driving functions. In effect, the lift will not allow itself to be used in an overloaded condition.

Figure: A crew of workers on a large Genie scissor lift platform. Modern MEWPs incorporate overload sensors that will stop the lift’s normal operation if the platform is carrying more than its rated capacity, preventing dangerous overload situations.

This feature helps ensure safety by design – operators must remove any excess weight before continuing work. It encourages proper assessment of the weight of tools and materials before elevating, since an overloaded MEWP simply won’t operate.

Chassis Angle Sensors (Tilt Sensing)

Chassis angle sensors, which reduce the risk of tip-overs, will be standard on new equipment

Many new MEWPs (especially models that in the past were rated for only flat, level surfaces) are now equipped with tilt sensors on the chassis. These chassis angle sensing systems detect when the machine is on a slope beyond its safe operating limit. If the MEWP is on too steep an incline, an alarm will sound and certain functions (like driving or boom movement) will automatically cut out. The operator will be prevented from raising the platform further until the machine is brought back to a safe level position.

Figure: A Genie boom lift operating on a rough slope. New MEWPs include dynamic terrain sensing – if the chassis exceeds the allowable tilt angle, the lift will automatically restrict boom and drive functions to reduce the risk of a tip-over.

This requirement means that newer boom lifts and other MEWPs will not allow unsafe use on slopes. Operators need to pay close attention to the terrain and may need to reposition or level the machine if the tilt alarm activates. The tilt-sensing feature is a direct response to accidents where lifts tipped over on uneven ground – now the machine itself helps prevent that outcome.

Indoor MEWPs

The new ANSI standards also introduced the concept of “indoor only” MEWPs. Manufacturers now have the option to design smaller, lighter lifts that are rated for indoor use only (often labeled as such on the machine). Because these indoor-rated MEWPs are not intended to be used in windy or other adverse outdoor conditions, they can be built lighter and more compact (which can be useful for navigating inside buildings).

An example of this is the new category of micro scissor lifts – very small, lightweight scissor lifts designed for indoor maintenance tasks. They might not have the robust wind resistance or heavy weight of an outdoor lift, but as long as they are clearly marked “indoor only,” they meet the standards. Operators must check whether a MEWP is rated for indoor-only or indoor/outdoor use and follow those restrictions accordingly.

Other Design Changes

A few other notable design requirements in the new ANSI A92.20 standard include:

- Entrance Gates: MEWP platforms must have a proper entry gate (such as a swinging gate or sliding mid-rail). Chain gates or flimsy flexible gates are no longer allowed. This change ensures there is a more secure barrier at the platform entrance that won’t accidentally come open.

- Toe Boards: All MEWP platforms are required to have toe boards (kickplates) on the edges of the platform floor. Toe boards help prevent tools or materials from sliding off the platform and falling on people below.

- Platform Railings: For certain small indoor scissor lifts, the minimum guardrail height has been raised. To still fit through standard doorways, some models now use taller fold-down railings instead of fixed railings. Operators may need to learn how to fold these rails when moving the lift through tight spaces.

All these design improvements are aimed at reducing common accident causes (such as falls from the platform or dropped objects). They also make the equipment more foolproof against misuse by building more safety into the machines themselves.

Conclusion

Mobile elevating work platforms are essential tools for many jobs – and now we have a clearer system to classify them and stricter rules to use them safely. In this guide, we covered what a MEWP is, the new ANSI classification by group and type, and the important changes in safety planning, training, and machine design that came with the latest standards. By understanding these updates, plant managers, operations directors, safety supervisors, and anyone else working with MEWPs can ensure they choose the right equipment and use it in compliance with current best practices.

Staying up-to-date with ANSI’s MEWP standards isn’t just about compliance. It’s about preventing accidents and protecting your workers. With proper risk assessments, rescue plans, comprehensive training, and modern equipment features, MEWP operations can be conducted more safely than ever.

If you have any questions about MEWP safety or need help selecting the right lift for your needs, Conger is here to help. As an authorized dealer for Genie, JLG, Snorkel and more, we offer a wide range of aerial lift equipment as well as training and support services to keep your operations safe and productive.

Stay safe up there!