Aerial lifts are mobile elevated work platforms that raise people and tools above ground in a controlled way. They replace ladders and scaffolding by providing a stable platform that moves to height. OSHA defines an aerial lift as a vehicle‑mounted device used to elevate personnel.

Knowing the types of aerial lifts helps you choose equipment that matches your job, reducing risks and saving time. This guide outlines the main categories and offers concise advice on choosing and using lifts safely.

What Is an Aerial Lift?

An aerial lift combines a work platform, extending structure and chassis so you can move vertically or horizontally to your work position.

Industry standards refer to these machines as Mobile Elevating Work Platforms (MEWPs).

Aerial lifts include boom platforms, articulating and telescopic booms, aerial ladders, and vertical towers. They are more flexible than scaffolding because you can drive them into place, raise the platform, and reposition as needed.

Industries such as construction, maintenance, warehousing and film rely on lifts to access overhead tasks. Because each category offers different heights and capabilities, understanding them helps you make smart decisions.

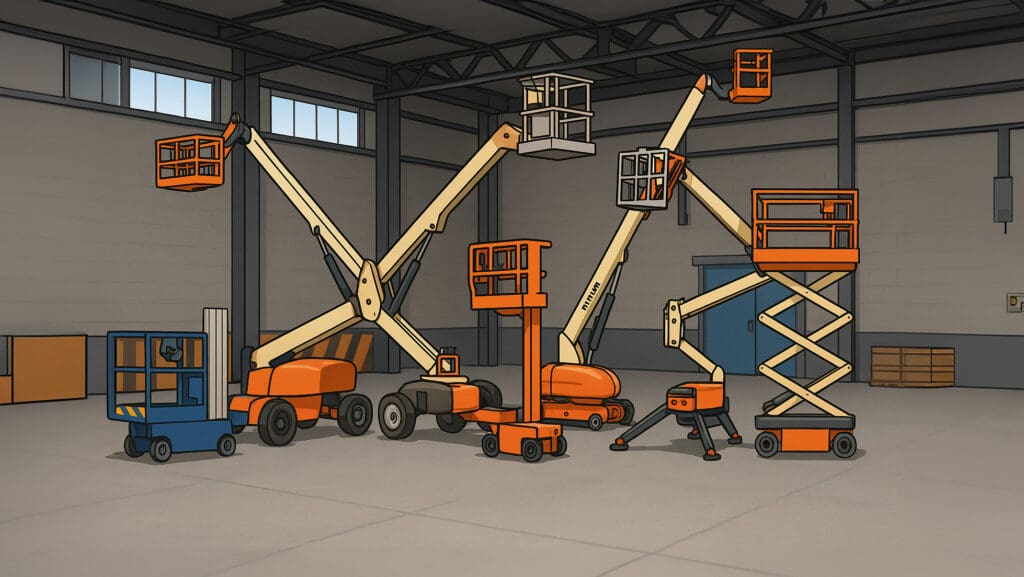

Major Types of Aerial Lifts

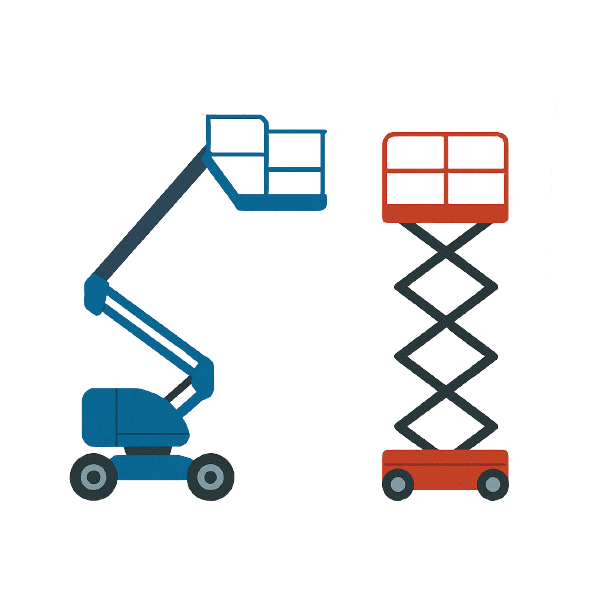

Several types of aerial lifts serve different needs. The major categories are:

- Boom lifts

- Scissor lifts

- Vertical mast lifts

- Atrium (spider) lifts

- Personnel lifts

- Towable boom lifts.

Each type offers unique advantages in height, platform size and maneuverability.

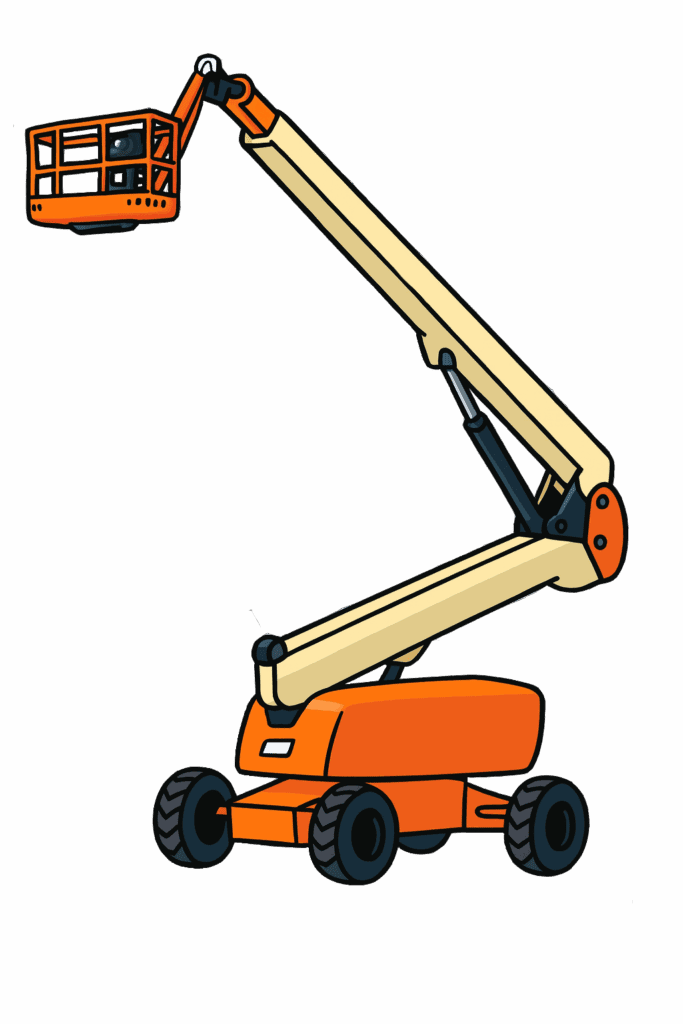

Boom Lifts

Boom lifts use a hydraulic arm with a bucket or platform at the end. Articulating booms bend at joints to go up and over obstacles, while telescopic booms extend in a straight line for maximum reach. Small models reach about 30 ft; the largest can exceed 180 ft. Platform capacities are typically 500 lbs to 1 000 lbs, enough for one or two workers.

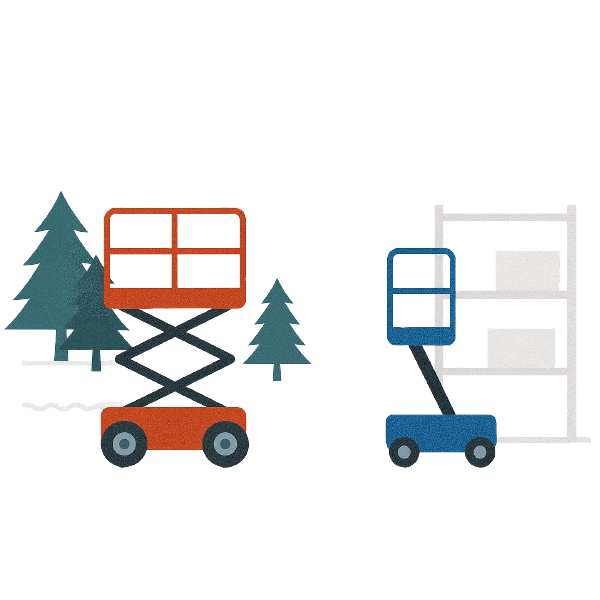

Boom lifts are ideal for jobs requiring horizontal outreach, such as exterior building repairs, steel erection or tree trimming. They usually run on diesel engines for outdoor use, though electric and hybrid versions exist. Because the boom swings out, these lifts need open space and careful attention to stability when fully extended.

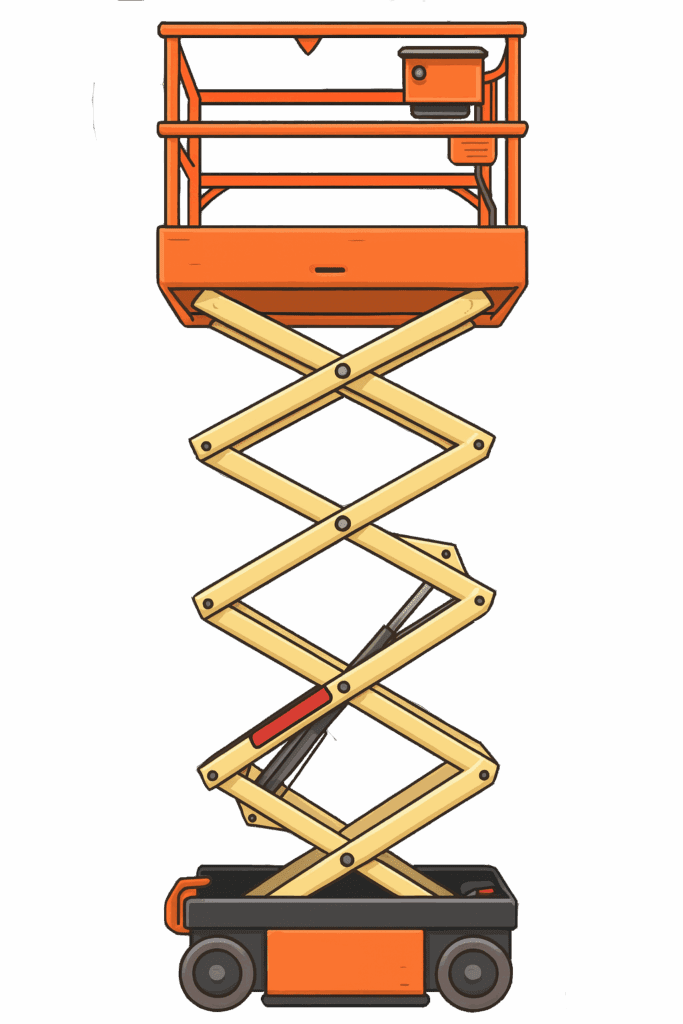

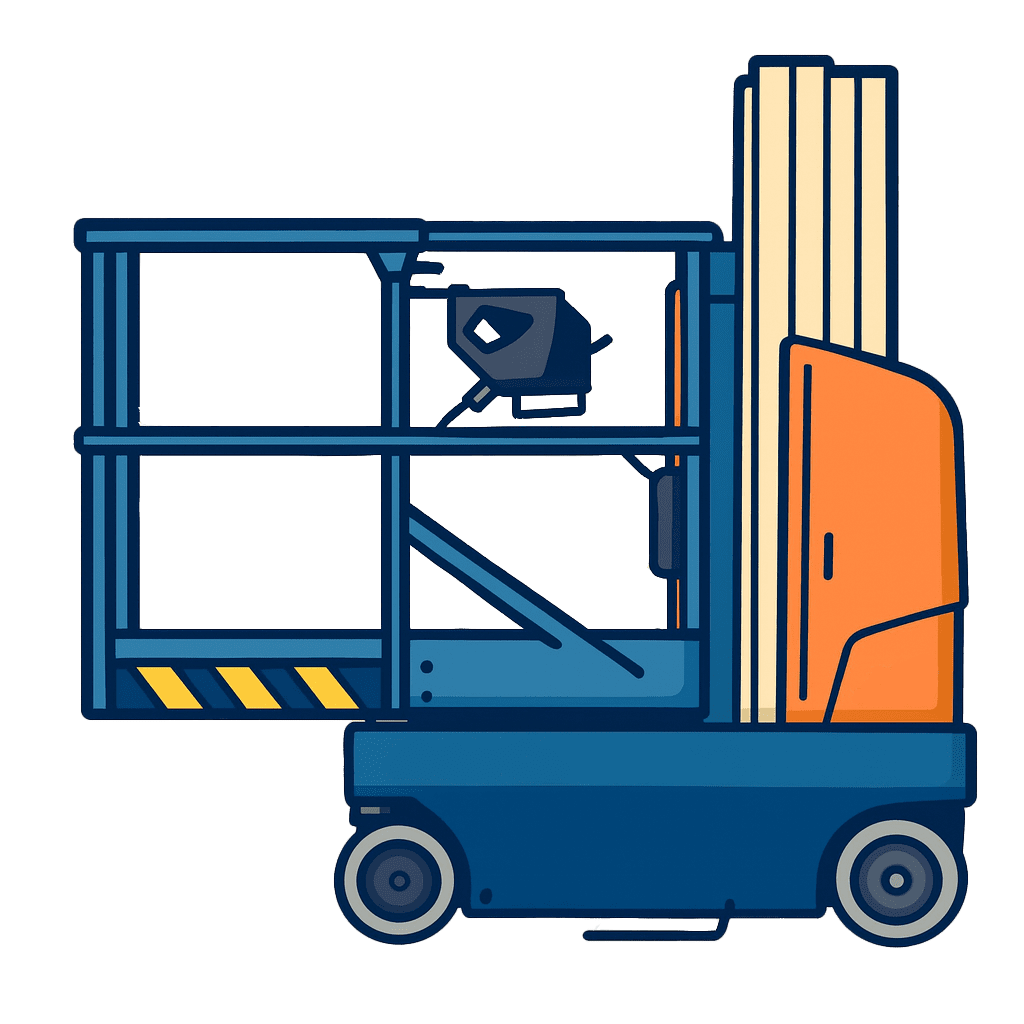

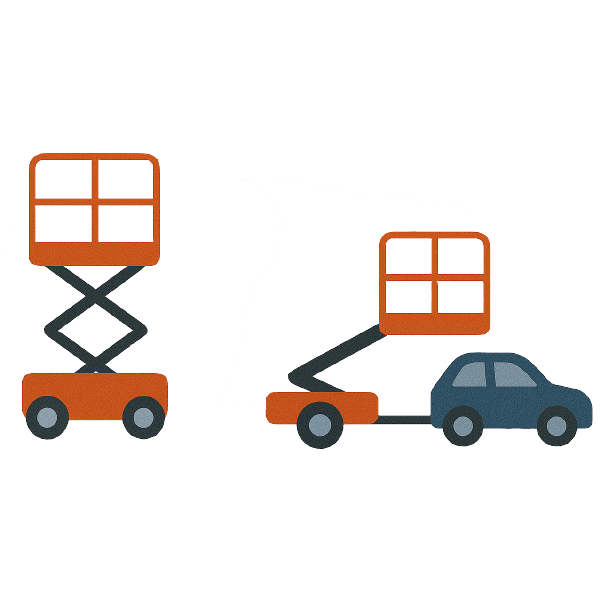

Scissor Lifts

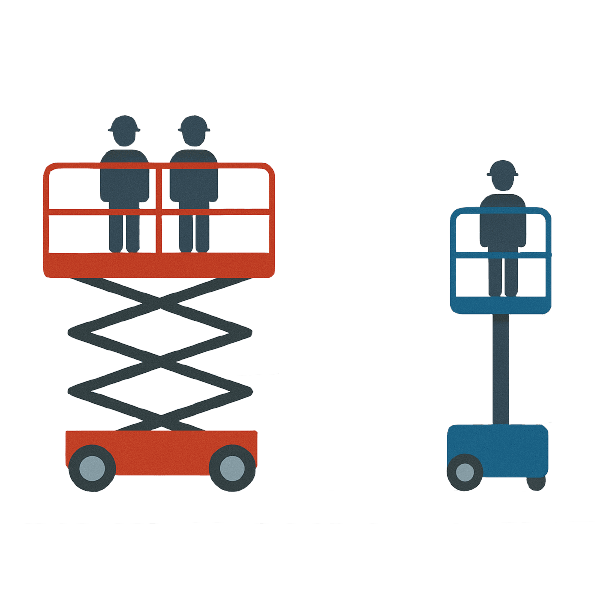

Scissor lifts provide a rectangular platform that moves only up or down. A crisscrossing support system raises the platform straight up. You must position the lift directly under the work area because it cannot extend outward. Typical heights range from 15 ft to 50 ft, and capacities from about 500 lbs on compact models to 1 500 lbs on rough‑terrain units.

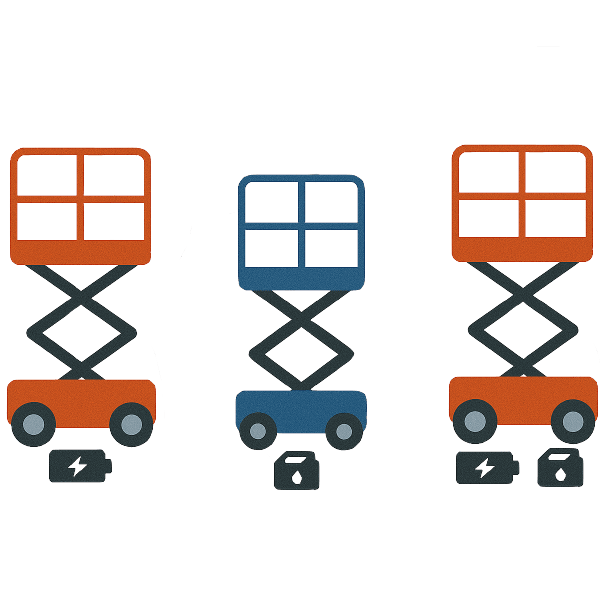

Electric slab scissor lifts are quiet and have non‑marking tires for indoor floors. Rough‑terrain scissors run on diesel and feature larger tires or outriggers to handle uneven ground. Use a scissor lift when you need a roomy platform for vertical work such as hanging lights, installing ductwork, or warehouse maintenance.

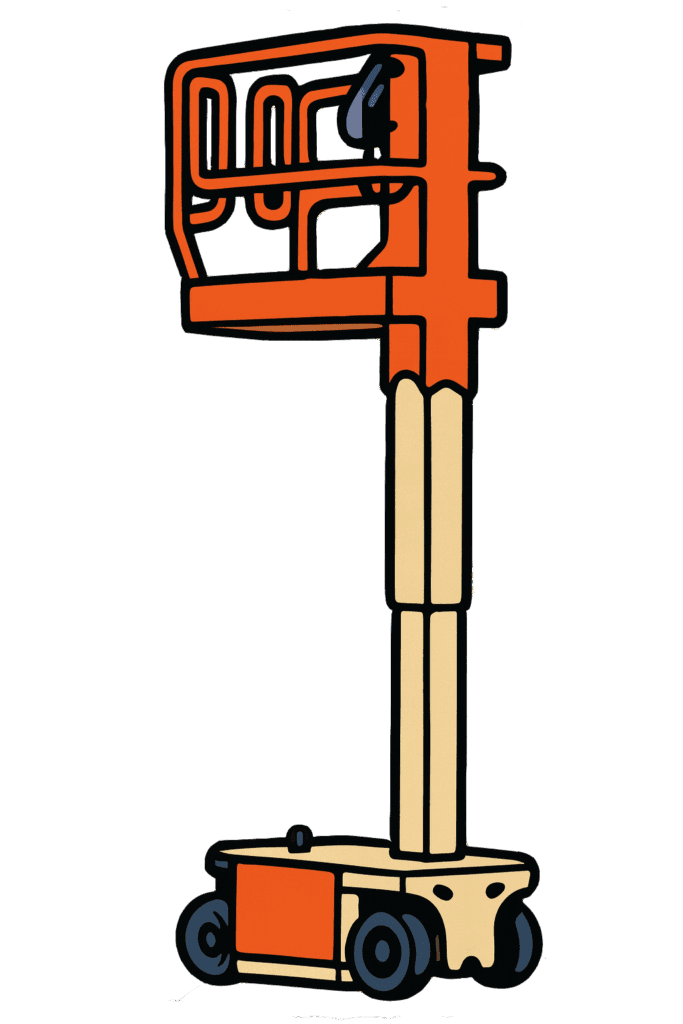

Vertical Mast Lifts

Vertical mast lifts (sometimes called man lifts) are slim machines designed for one person. A telescoping mast raises a small platform straight up; some models fit through doorways or into elevators. Self‑propelled versions allow you to drive from the platform, while push‑around units are manually moved into position. Heights typically range from 15 ft to 30 ft and capacities from 300 lbs to 500 lbs.

Mast lifts use outriggers or stabilizers for safety. They are electric and well suited to indoor maintenance tasks such as changing lights, fixing drop ceilings or picking stock in tight aisles. Their narrow footprint makes them perfect for spaces where scissor lifts or booms cannot fit.

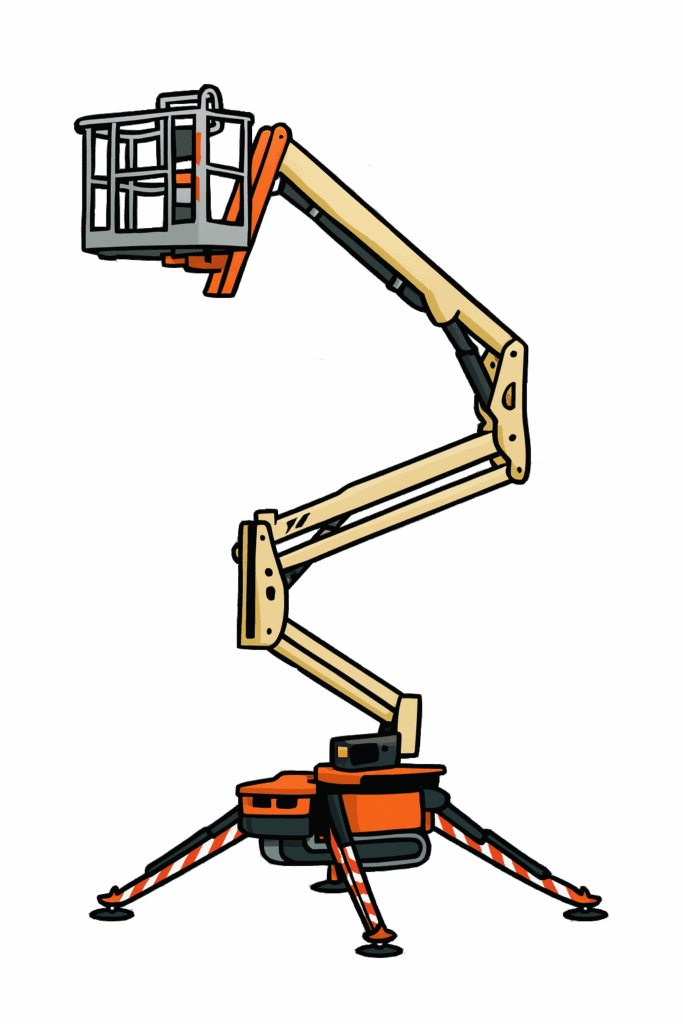

Atrium (Spider) Lifts

Atrium or spider lifts collapse into a very narrow tracked chassis that fits through doors. When set up, outriggers extend like spider legs to level and stabilize the machine on uneven ground. Many spider lifts offer working heights between 30 ft and 70 ft, and some reach 85 ft or higher.

They often run on battery power indoors and a small engine outdoors. An articulating boom allows you to maneuver around obstacles and into high atriums, church naves or tree canopies. Platform capacities are lower (around 440 lbs to 500 lbs), and movement is slower than full‑sized booms. Choose a spider lift when you need high reach in tight spaces or on delicate surfaces.

Personnel Lifts

Personnel lifts, sometimes called push‑around lifts, are the smallest and most portable class of aerial lifts. Workers manually roll the unit into position, deploy stabilizing outriggers, climb into the basket and raise themselves. Typical working heights are 20 ft to 40 ft, with capacities around 300 lbs.

Many units can be disassembled and carried up stairs or through elevators. These lifts are battery‑ or AC‑powered and designed for quick, one‑person jobs in offices, schools, and retail stores. Use them when you need a safer alternative to a ladder for tasks such as changing lights or hanging signs.

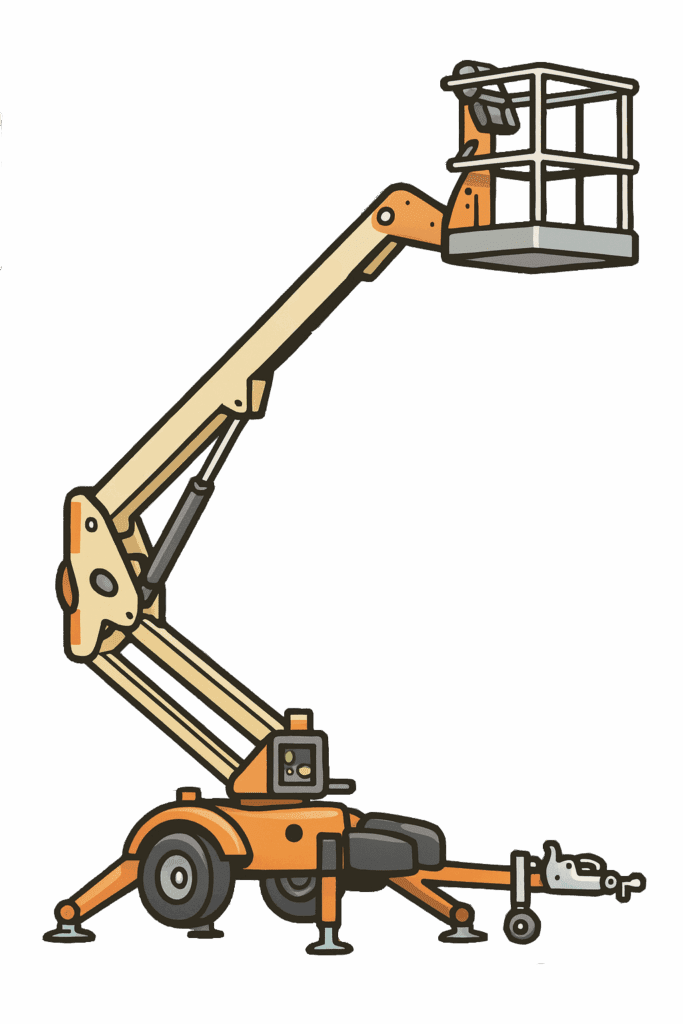

Towable Boom Lifts

Towable boom lifts mount a boom on a trailer chassis that can be towed behind a vehicle. Platform heights range from 30 ft to about 65 ft and capacities around 400 lbs to 500 lbs. They use outriggers to stabilize and often run on batteries or small gas engines.

Towable lifts are popular with contractors, painters and homeowners because you can transport them with a pickup truck. Once on site, you unhitch the trailer, deploy the outriggers and operate the boom like a standard lift. These units are slower to reposition than self‑propelled booms but provide a cost‑effective solution for occasional jobs.

Aerial Lift Comparison Chart

| Lift Type | Typical Height (ft) | Platform Capacity | Key Benefit |

| Boom lift | 30–180 | 500–1 000 lbs | High reach and horizontal outreach |

| Scissor lift | 15–50 (some to 60) | 500–1 500 lbs | Large platform for vertical tasks |

| Vertical mast lift | 15–30 | 300–500 lbs | Compact and fits through doorways |

| Atrium / spider lift | 30–85 | 440–500 lbs | High reach in narrow spaces |

| Personnel (push‑around) | 20–40 | 300 lbs | Portable one‑person tasks |

| Towable boom lift | 30–65 | 400–500 lbs | Portable boom, towable by vehicle |

Note: These are general ranges; always consult the manufacturer’s specifications for exact measurements.

Choosing the Right Aerial Lift

When selecting a lift, match the equipment to your job requirements. When selecting a lift, match the equipment to your job requirements:

Height and Outreach: Identify the maximum height and whether you need horizontal reach. Use booms for reach over obstacles and scissor or mast lifts for straight vertical access.

Capacity and Platform Size: Count how many workers and how much material you need to elevate. Scissor lifts generally offer bigger platforms and higher capacities; personnel lifts and mast lifts are for one person and small loads.

Terrain and Space: Determine whether your job is indoors on smooth floors or outdoors on rough ground. Rough‑terrain models offer four‑wheel drive and bigger tires; slab lifts have non‑marking tires for indoor use. Measure doorways and aisles to ensure the lift fits.

Power Source: Choose electric lifts for indoor or noise‑sensitive environments and diesel engines for outdoor power and long run times. Hybrid lifts can handle both settings but cost more.

Mobility and Transport: Decide if you need a self‑propelled unit or a towable lift. Self‑propelled booms and scissors reposition themselves easily; towable booms are best when you need to move between job sites.

Evaluating these factors will help you pick a lift that completes your project efficiently and safely.

Safety Considerations

Operating aerial lifts safely is essential to protect workers and comply with regulations. OSHA and ANSI provide clear guidelines:

- Training and Authorization: Only trained and authorized personnel may operate lifts. Training should cover machine controls, hazard recognition and emergency procedures.

- Fall Protection: Boom lift operators must wear a harness and lanyard attached to an anchor point because there is a risk of ejection. Keep guardrails raised and gates closed on scissor lifts; some employers require harnesses there too.

- Stability and Setup: Deploy outriggers or stabilizers when required and ensure the lift is on level ground within its rated slope. Never exceed platform capacity or drive a lift while elevated unless the manufacturer allows it. Respect wind ratings and lower the platform if conditions worsen.

- Electrocution Hazards: Maintain at least a 10‑ft clearance from overhead power lines and treat all lines as live. Use insulated equipment when working near electrical infrastructure.

- Inspection and Maintenance: Perform a pre‑operation inspection each shift. Check tires, batteries or fuel levels, controls, emergency lowering functions and safety devices. Do not operate a lift with any defect; tag it out and have it repaired.

By following these guidelines and manufacturer instructions, you significantly reduce the chance of accidents.

Conclusion

Understanding the types of aerial lifts helps you choose equipment that matches your height, reach and terrain requirements. Boom lifts provide height and outreach; scissor lifts offer spacious platforms for vertical jobs; vertical mast and personnel lifts work in tight indoor spaces; atrium lifts solve access challenges where doors and floors are narrow or delicate; and towable booms deliver portable height for occasional tasks.

Evaluate height, capacity, terrain and power needs before renting or buying a lift, and ensure operators are trained. Conger Industries offers a wide range of aerial lifts for sale or rent. Our experts can help you select the right lift, provide training and support, and ensure you complete your work safely and efficiently. Contact us today to discuss your project and find the perfect solution.