We analyzed 6,220 forklift repair service calls to answer the question:

What are the most common forklift issues?

Then we dug a little deeper to determine what it took to fix them.

And in this post, we’re going to share what we discovered.

Let’s dive in.

[Update] The Most Common Forklift Repairs from 2020

Instead of running another data study this year, we thought we’d go another route.

We decided to talk to our resident experts on forklift repair: Our technicians.

We asked them two questions:

- What are the 3 most common repairs you performed in 2020?

- What’s your best piece of advice for keeping a forklift running well?

Here’s what they had to say:

Top Issues:

“I’ve seen a lot of the usual this past year: Blown hydraulic hoses, chunked out tires, burnt out light bulbs, horns that don’t work, and parking and service brakes that need adjustments. I’ve also seen a lot of damage, like broken light brackets and smashed side panels.”

Advice:

“Have a professional look at your trucks. Make sure to schedule routine maintenance. And also make sure that operators are not only doing their daily checklist, but also that you’re following through and repairing any items that are found to be deficient.”

Top Issues:

“Lots of hose issues, for one. And lots of battery maintenance issues as well. Things like batteries not being watered regularly, and not keeping batteries clean and free of corrosion. I’ve also replaced a ton of pedal pads, which is a big safety issue. Just a slip of the foot can cause the fork truck to run off a dock or smash into someone. Beyond that, it’s been a lot of parking brake adjustments and horn contacts replacements. I noticed that a lot of the reason for replacing horn contacts stems from not lubricating them. Unless you lubricate them, they’re just going to wear out quicker.”

Advice:

“A good quality preventative maintenance (PM) check goes a long way. If you keep up on it, your fork trucks will last a long time. In fact, I’ve got an account with 7 trucks that have over 100,000 miles on them! And the reason that they’ve lasted so long is that I’ve maintained them regularly from when they were brand new. It all comes down to changing the fluids regularly and keeping them clean. Do that and you won’t have serious and expensive issues, like blown motors.”

Top Issues:

“In a word: Destruction. I’ve replaced 2 overhead guards that were destroyed, several broken masts, multiple tilt cylinders that were ripped right off, and a steer cylinder that was broken right off the mounting. A lot of the problem is operators driving too fast and taking corners too fast. Some of my customers have turned down speeds on their forklifts only to have them turned back up again somehow. Plus with COVID-19, some of my customers are struggling to keep up with demand. I’ve got one account that normally runs 8-hour shifts that are now doing 14 to 16 hour shifts. That’s made it very difficult to keep up on maintenance. Plus, with labor shortages, a lot of companies are hiring operators who just aren’t careful with their lift trucks. So there’s been a lot of damage on account of that.”

Advice:

“Train your operators and get them to do daily inspections. Make sure they know how to do simple things that go a long way, like popping the hood and checking the oil level. I would also say that increasing operator accountability for damage will help cut down on expenses. And consider keeping common parts on hand at your location. That way, you don’t have to worry so much about having your forklift out of commission if the parts aren’t available right away.”

Top Issues:

“The biggest thing that stands out to me in the last year was an increased focus on safety. I’ve replaced a ton of frayed seat belts, torn seats, backup alarms, strobe lights, blue lights, and other safety items. I think the reason for this is because a lot of operators have been taking our updated forklift operator training. That, along with OSHA’s forklift regulations, has made them more aware when things are wrong and safety is compromised. So they go ahead and notify management, and management gives us the go-ahead to get the repairs taken care of. “

Advice:

“It really all starts with the operator: Better operator training leads to managers becoming more aware of safety issues, which gives us techs the authorization to fix the issues. Besides that, a good PM service is a must. And as far as preventing damage, speed control can really help with that. I know lots of companies think that reducing the speed of their lift trucks reduces productivity. But that’s not actually true. In fact, there was a study a few years’ back that showed the opposite: Lift trucks with speed control actually outperformed those without it!”

Top Issues:

“Damage. I’ve had 2 fork trucks that have fallen off docks or out of the back of trailers. A lot of the other damage I’ve seen is a little more minor, like broken brackets and slight damage to overhead guards.”

Advice:

“Better operator accountability plus a good PM service. But you can’t buck the repairs when they’re noted on the PM. If you do, they’ll just become more expensive and severe the more they’re ignored.”

Top Issues:

“I’ve seen a lot of the ordinary, like blown or old hoses that needed to be changed out. I’ve also done a lot of seat replacements due to rips and tears. Plus, there’s been a lot of power steering brushes and hydraulic contacts that I’ve replaced. Just regular wear and tear items. I’ve also replaced at least 3 display boards on order pickers too. I’ve seen a little bit of damage to overhead guards as well, mostly from issues with mis-fitted racking.”

Advice:

“Make sure there’s a quality PM being done. And follow through on what the technician recommends! The way I look at it, we’re hired to come in and find anything that’s wrong with your trucks. So we’re looking for things that can be fixed before they become bigger problems. But if the customer doesn’t follow through with the repairs that we recommend, then what’s the point?”

Top Issues:

“Lots of repairs from damage. I’ve had to replace forks, fork positioners, and side shifters that were torn off the carriage. I’ve also had to do a lot of repairs that were caused by excessive salt. Things like steer pins and axle pivot bushings that were corroded out. Beyond that, it’s been a lot of the usual preventative maintenance (PM) things.”

Advice:

“Keep your trucks clean! Especially if you run outside and use a lot of salt on the ground. Salt just corrodes the heck out of lift trucks. It wreaks havoc on electrical systems, the mast, the body, the steer axle and all sorts of other things. But if you spray your trucks down regularly, you can help to cut down on the rust.”

Top Issues:

“I have had a ton of broken wires for the mast switch. A bunch of fuel filters plugged up, too. It seems like some places have real dirty fuel or rusty tanks. I had a rash of fan belts breaking on trucks with low hours. They just seem to be separating. Lastly, a lot of transmission hoses and o-rings on the fittings leaking on trucks with less than 4,000 hours.”

Advice:

“Just maintain it. Neglect shortens a forklift’s life. A good PM will catch a lot of the problems – especially on Toyota’s.”

Summary of Our Findings from 2019

Top Complaints

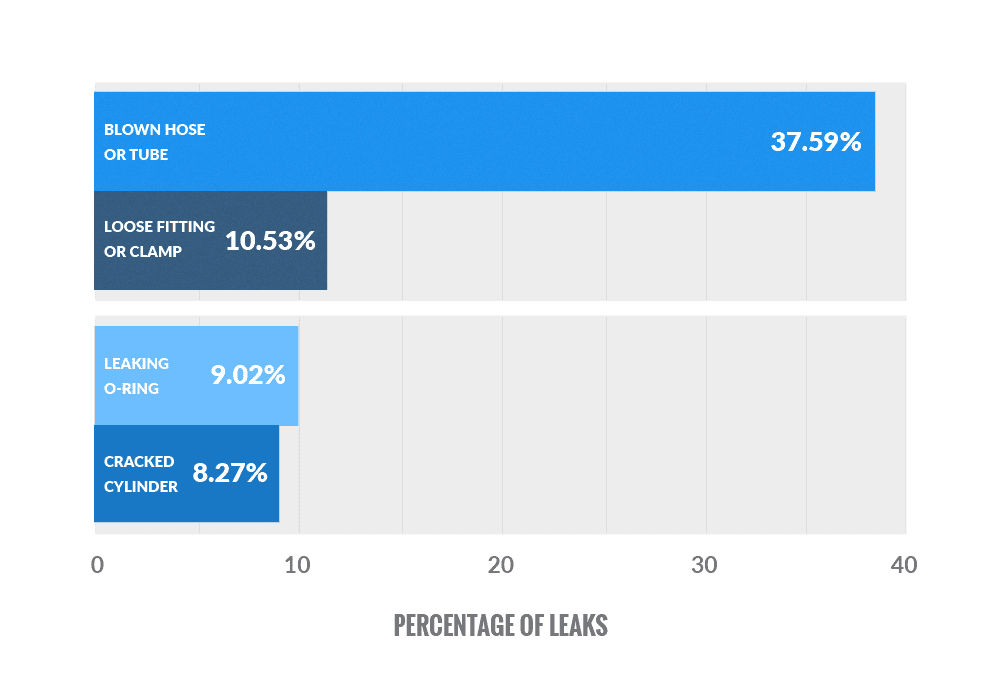

1. At 20.4% of all work orders surveyed, the biggest category of reported issues was leaks. The most common culprits were blown hoses and damaged tubing, which accounted for 37.59% of all reported leaks.

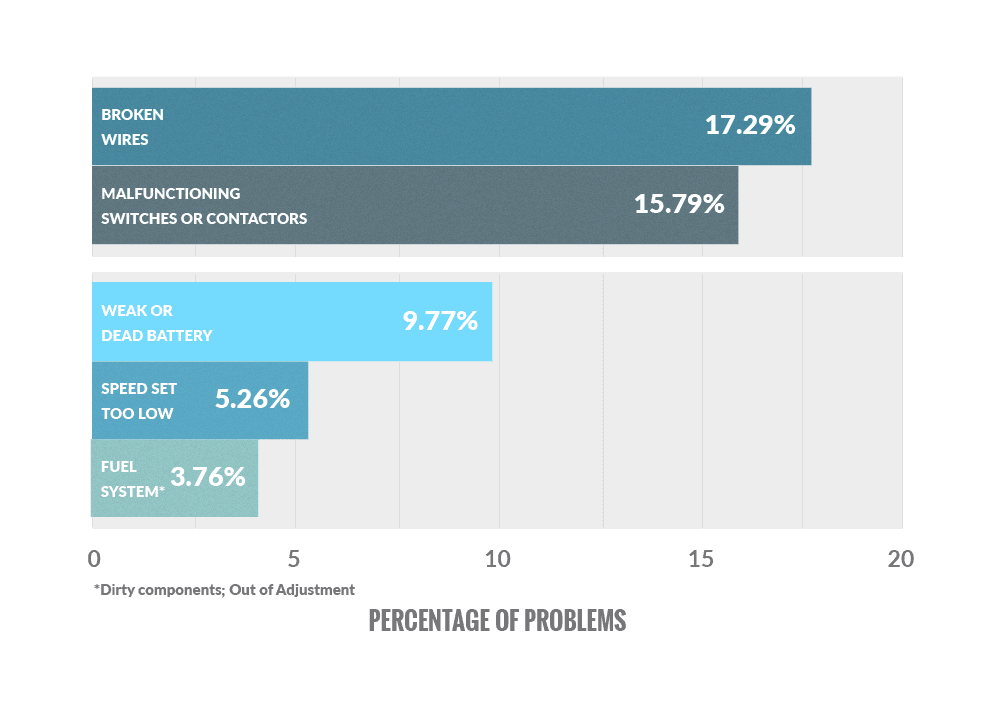

2. Travel and lift issues came in second among surveyed work orders, at 15.18% of complaints. Broken or corroded wiring accounted for 17.29% of root causes, the largest among all causes.

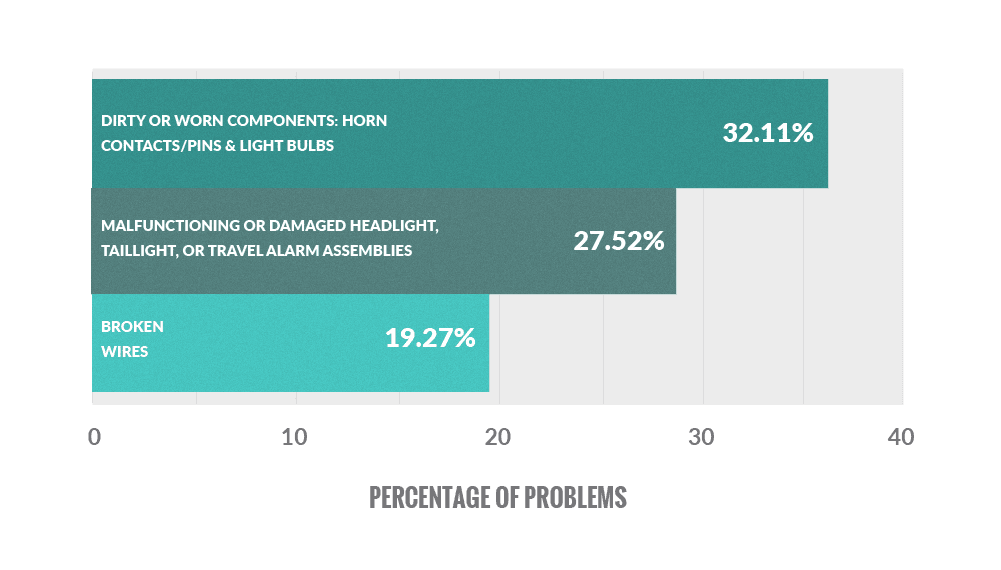

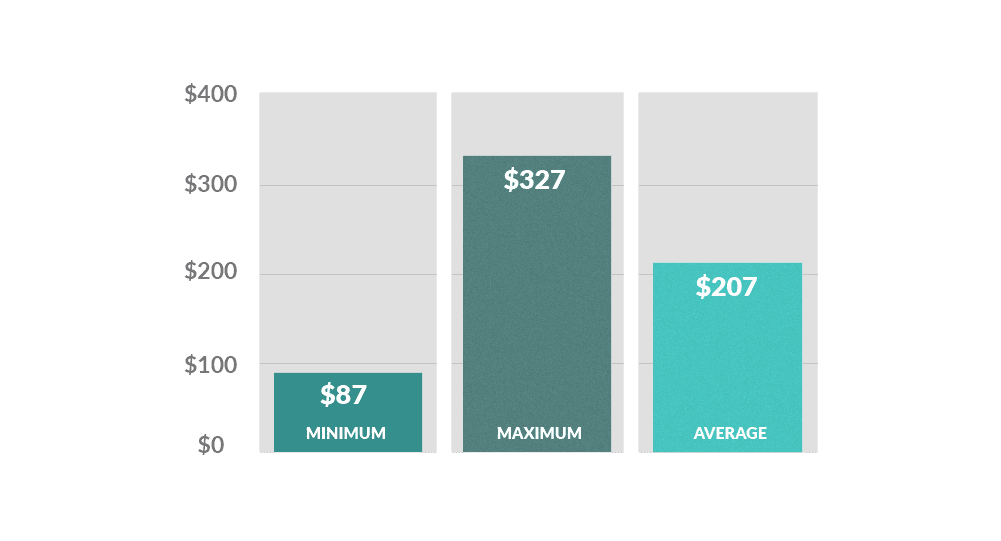

3. Accessory (horn, travel alarm and lights) issues came in third place with 13.89% of work orders. In the majority of cases (32.11%), cleaning or replacing parts solved the problem.

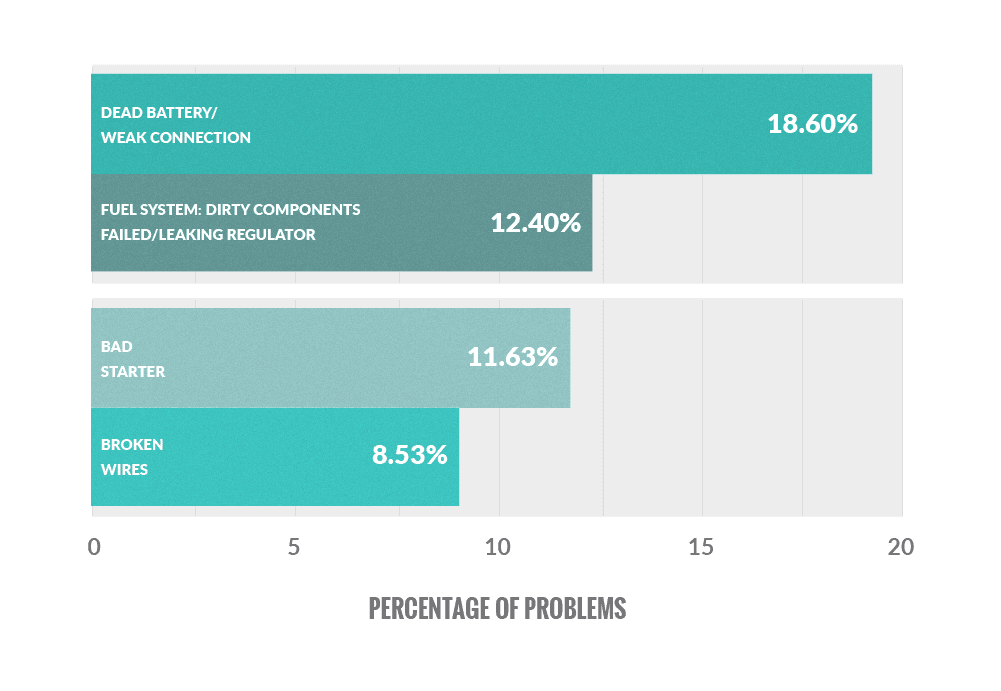

4. In fourth place were starting issues, at 12.89% of our survey sample. We found that 18.6% of the time, the cause was a dead battery.

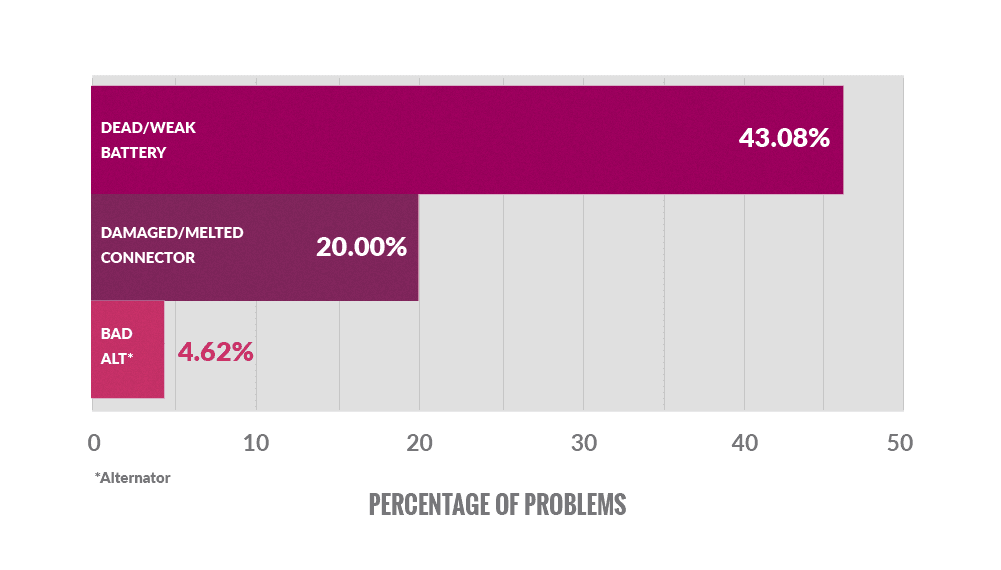

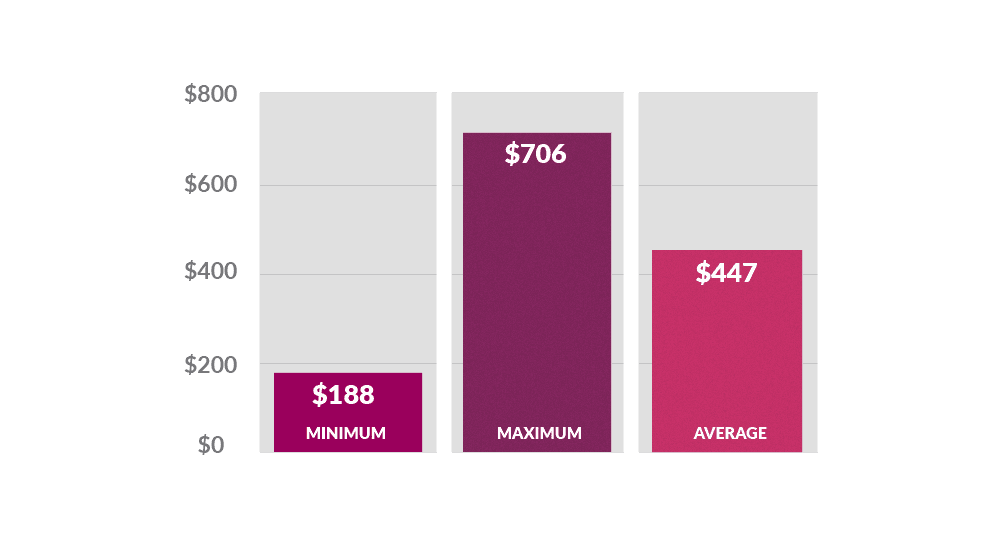

5. General battery complaints made up the next most frequent complaint, with 10.53% of the total work orders surveyed. Most of the time (43.08%), replacing or charging the battery or batteries solved the problem.

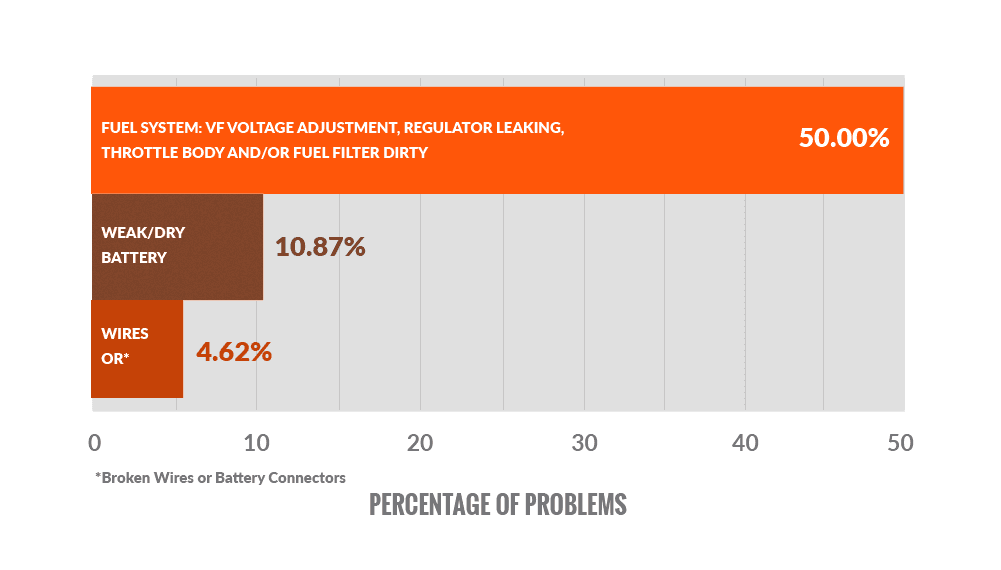

6. The next most common complaint (7.49%) was that the unit was running rough. Cleaning or making adjustments to the fuel system resolved the issue in 50% of the cases.

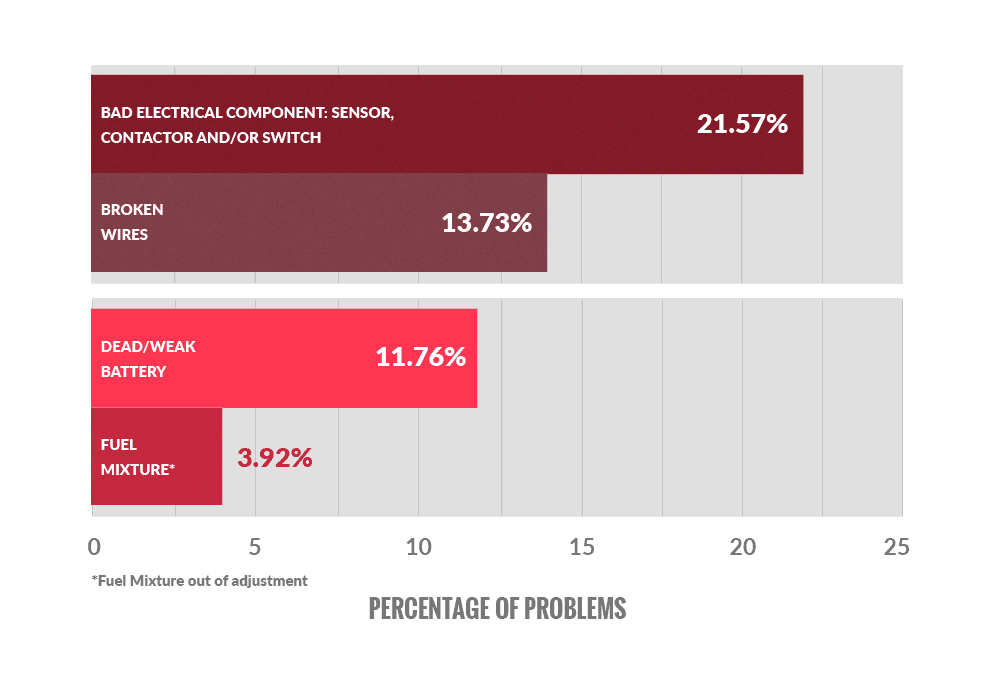

7. Error codes and check engine lights came in next, with 6.21% of surveyed issues. Faulty electrical components were most often the culprit with 21.57% occurrence.

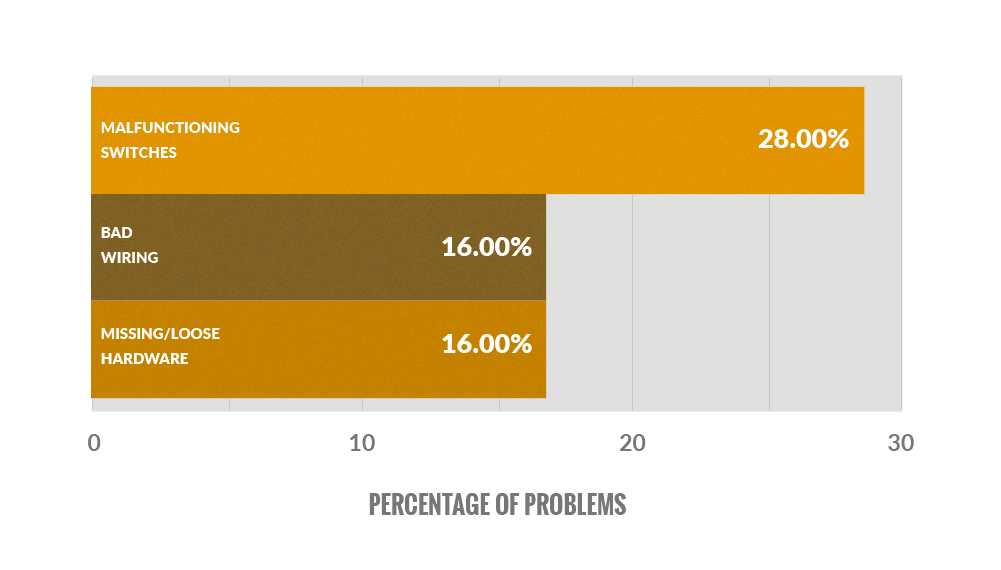

8. Electrical issues, including problems with buttons, switches, and pedals were next, with 5.14%. Faulty switch assemblies were the most common root cause at 28% of issues.

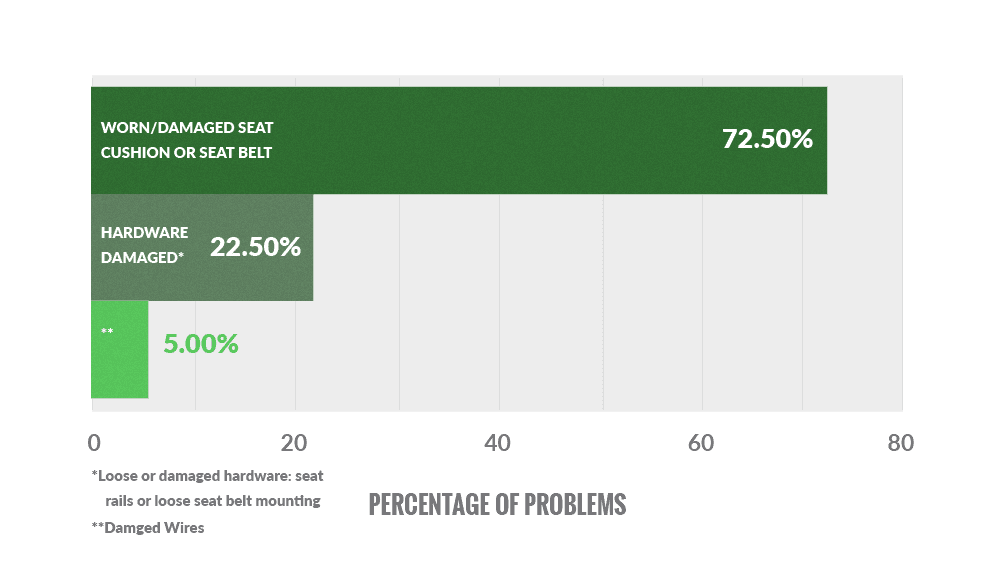

9. Seat and seat belt issues were eighth, with 4.26% of complaints. In 72.5% of cases, the entire assembly (seat belt, seat or cushion) needed to be replaced to fix the reported issue.

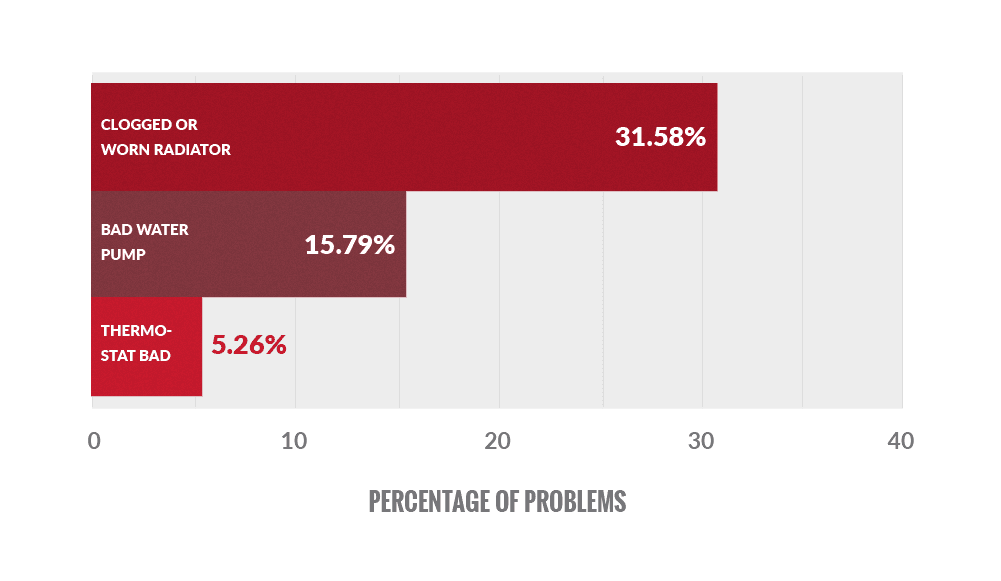

10. The smallest number of issues in our survey concerned the cooling system, with 4% of the sample. In the majority of cases (31.58%), replacing or cleaning the radiator solved the problem.

Keep reading for more detailed information from our findings.

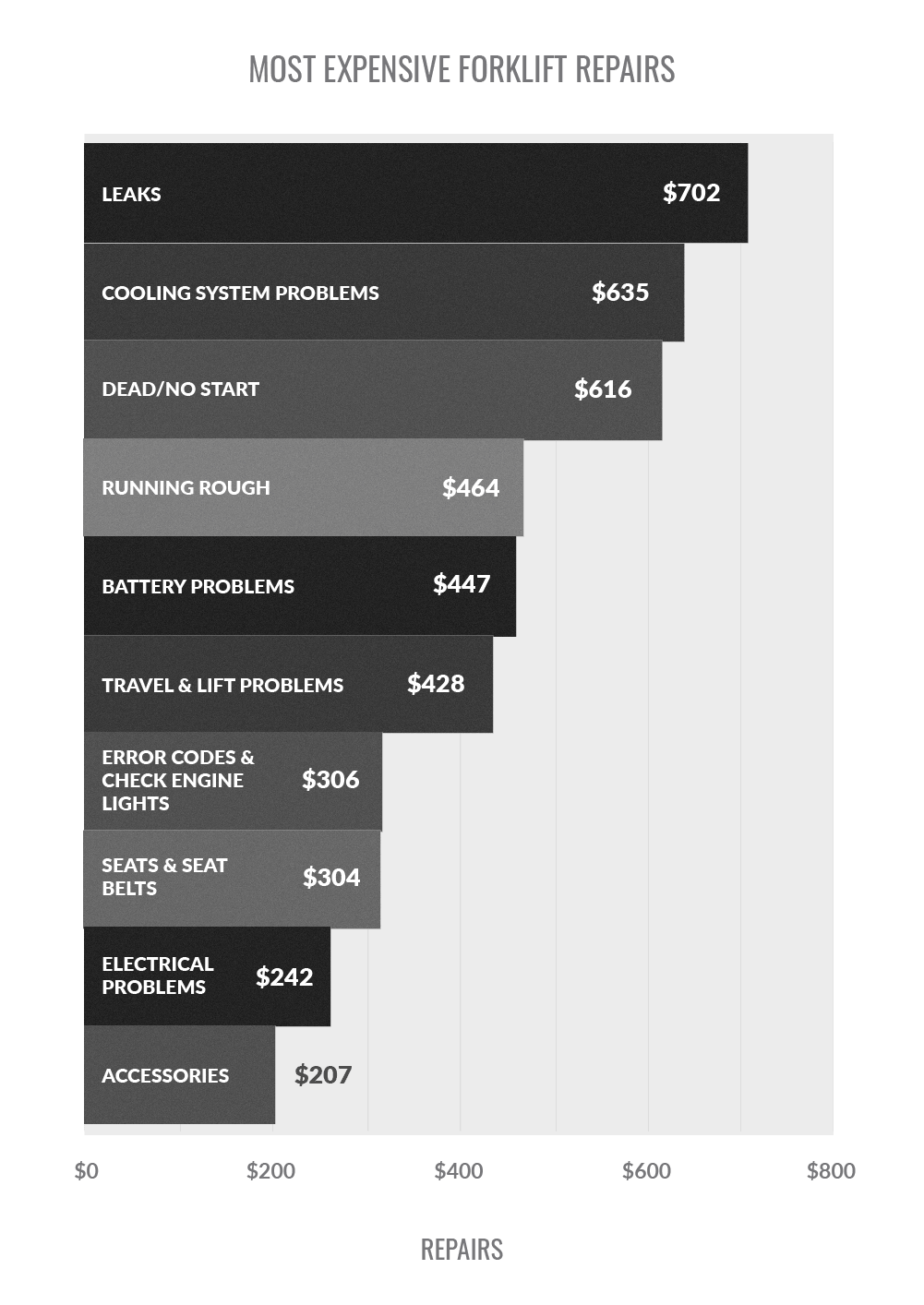

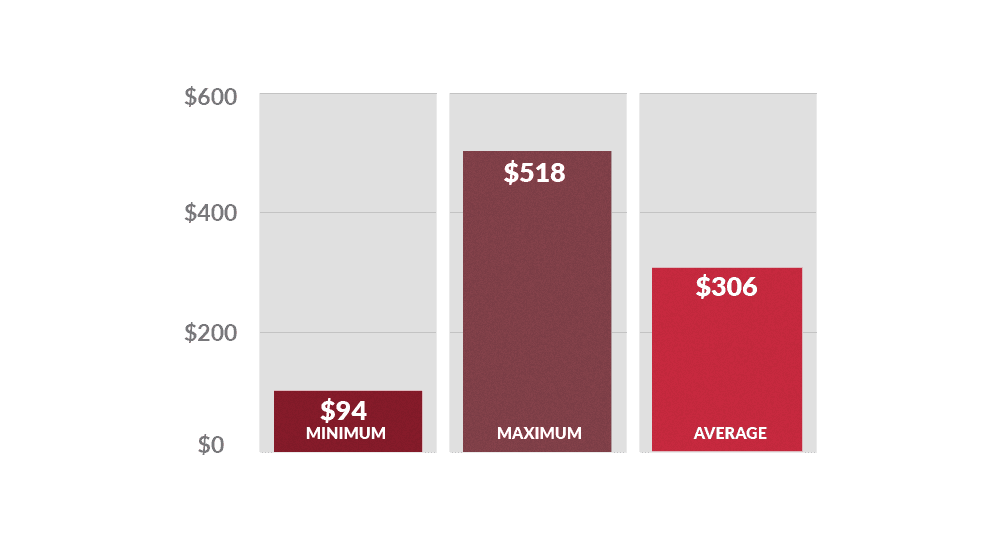

The Most Expensive Forklift Repairs

Our Findings From 2019

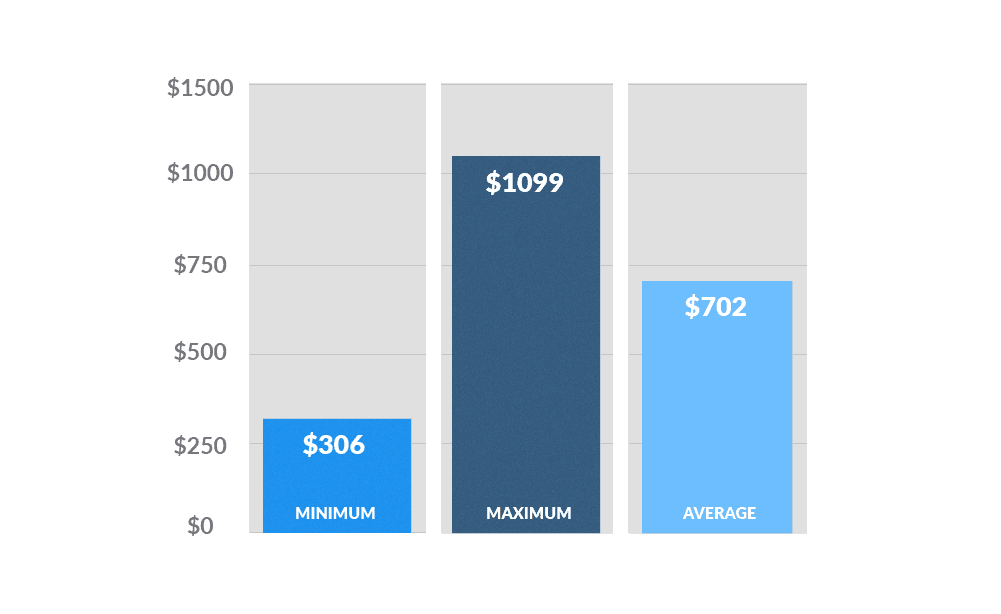

#1: Leaks

Forklifts have several fluid systems, including the hydraulic, cooling, and steering systems.

Unfortunately, components in these systems like hoses and o-rings start to wear down over time. And when that happens, leaks occur.

Overall, we counted 1,269 leak-related issues in all of 2019, accounting for 20.4% of all work orders surveyed.

Most Common Causes of Leaks

Less Common Causes of Leaks

Bad engine seal

Bad control valve seal

Bad planetary gear seal

Loose oil filter

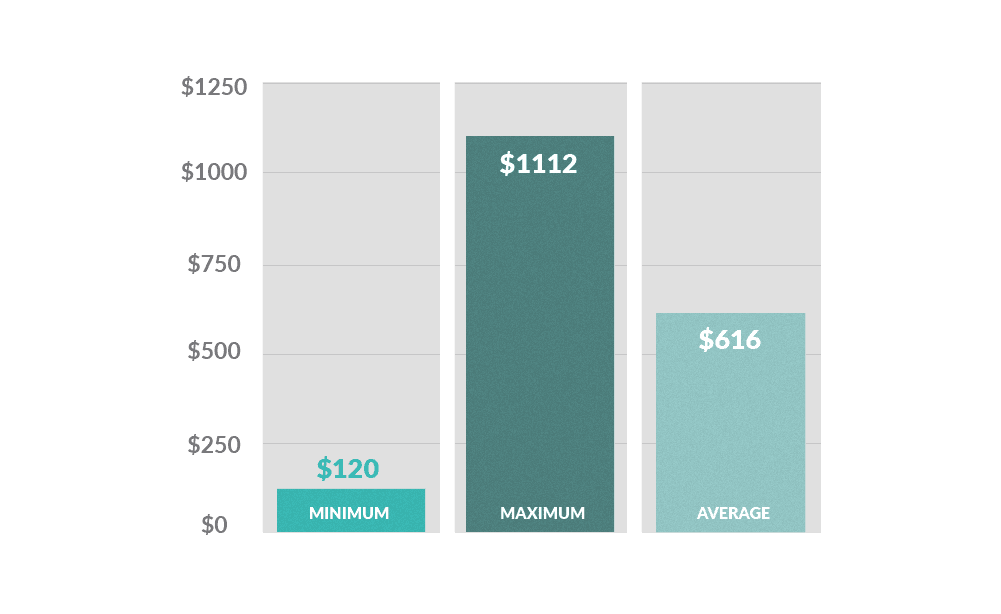

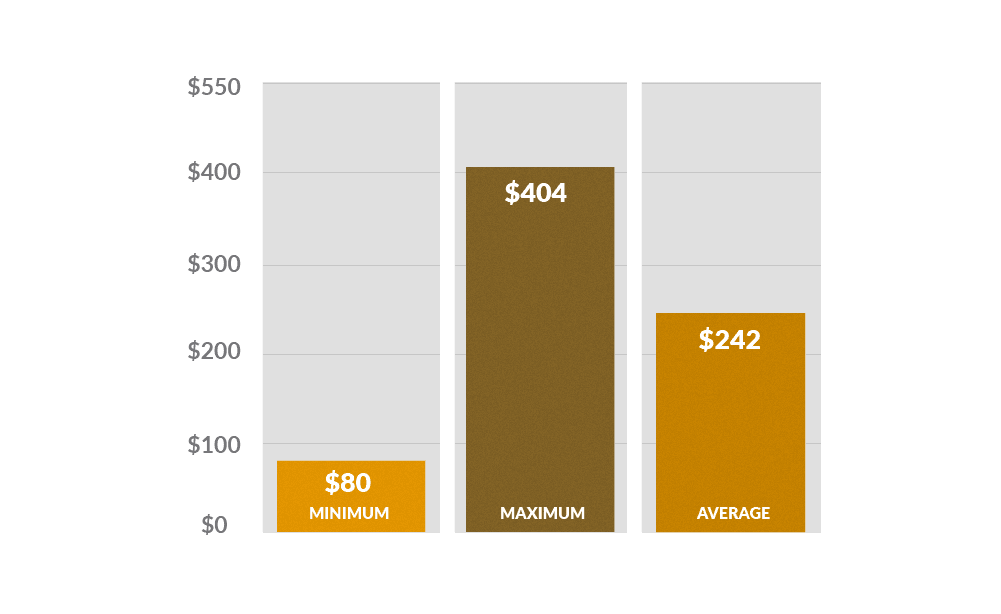

Average Costs Across All Leak Repairs

What About Safety?

Every leak issue listed here is a potential safety issue for operations that have a zero-tolerance policy for fluids on the floor.

But even if no such policy exists, fluid accumulation can put employees in danger of slipping and injuring themselves.

What Can You Do to Prevent Leaks?

Check Hoses for Wear

Since most issues involved blown hoses, a regular maintenance program can help identify those hoses that are worn and at greatest risk of failing.

Why do hoses blow?

The fluid in a forklift’s hydraulic system is under enormous pressure.

In order to cope with that pressure, hydraulic hoses are composed of a metal wire framework covered in thick rubber.

While any hose will wear out over time, the problem is made worse when you add movement to the equation.

When hoses move, like those that travel up and down with the forklift’s mast, the rubber wears down until the metal framework underneath is exposed.

And when that happens, hoses are at an increased risk of blowing.

Check for Loose Fittings and Clamps

Loose fittings and hoses can also be caught in this process and corrected before they become a problem.

Check for Seeping

Other issues, like leaky o-rings and cylinder seals, are more difficult to predict. They tend to wear over time, and so timing failure is a bit of a guessing game.

That being said, a watchful eye can alert you to when a fitting or o-ring is beginning to weep.

A leak is when fluid hits the ground. But a weep is when fluid begins to seep out without hitting the ground. And if caught, the weeping part can be replaced before turning into a leak.

#2: Travel & Lift Problems

A forklift mast that won’t go up or a lift that won’t stay running present problems for operators and management alike.

Not only does it cost money in terms of lost productivity, but it also means an extra repair bill.

Overall, we counted 944 travel and lift-related issues in 2019, making up 15.18% of all work orders surveyed.

Most Common Causes of Travel and Lift Problems

Less Common Causes of Travel and Lift Problems

-

Debris in the hydraulic pump

-

Check valve blockage

-

Locked up brake

-

Weak battery

-

Bad motor

Why do wires break so often?

Heat + Age + Movement.

The hotter a wire gets, the more brittle it becomes. Combined with an aging unit and movement, that brittle wire can easily snap, causing a potential multitude of problems.

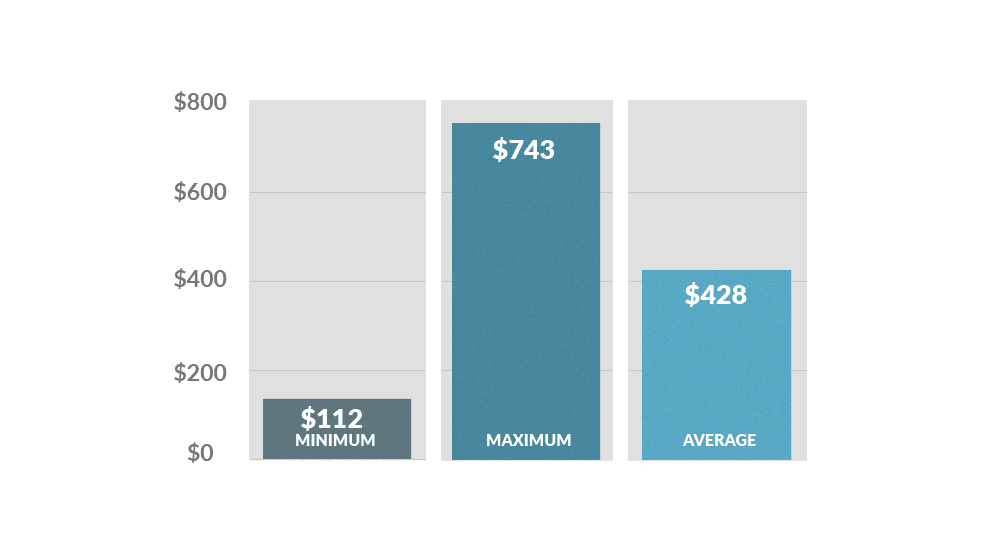

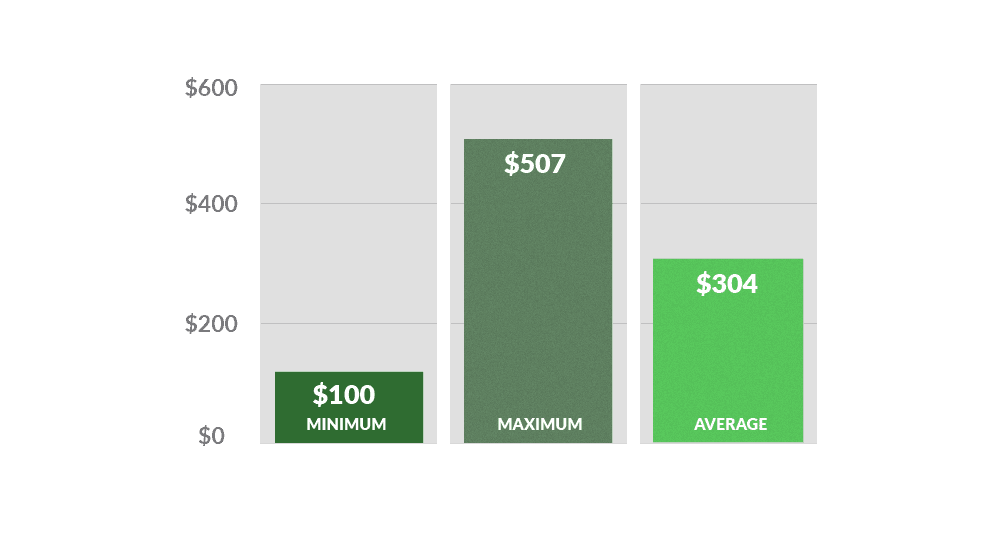

Average Costs Across All Travel and Lift Repairs

What About Safety?

Though coming in fifth place with only 3.76% occurrence, fuel system issues involving the regulator are most worrisome.

A leaking regulator can cause higher levels of emissions. And that can endanger those who work in the same space.

What Can You Do to Prevent Travel and Lift Issues?

Tape Exposed Wires

While broken wires and faulty switches were the cause of some travel and lift problems with internal combustion forklifts, they were mostly found in electric forklifts. Malfunctioning contactors, on the other hand, were exclusive to electric trucks.

Unfortunately, these issues tend to reveal themselves without warning.

But, there are a couple of things that can help lessen the likelihood of failure.

Adding electrical tape or proper insulating material (if in the case of battery wires) to an exposed wire is one step. And keeping the movement of components to a minimum is another.

Keep Batteries Watered and Charged

Battery issues, however, can be prevented by performing proper maintenance. Keep them watered, charged, and out of use until completely charged.

Adjust the Fuel System and Remove Gunk

Fuel system issues, though a less frequent cause of movement issues, can be prevented with regular maintenance.

That maintenance should include cleaning the fuel system and making sure it’s properly adjusted. Also, make sure to drain the regulator periodically. That can help clear it of built-up gunk, thus preventing issues in the first place.

Additionally, make sure that the steering, drive, and motor pump brushes are regularly being checked. Cleaning or replacing worn or dirty motor brushes can save you a lot of trouble down the road.

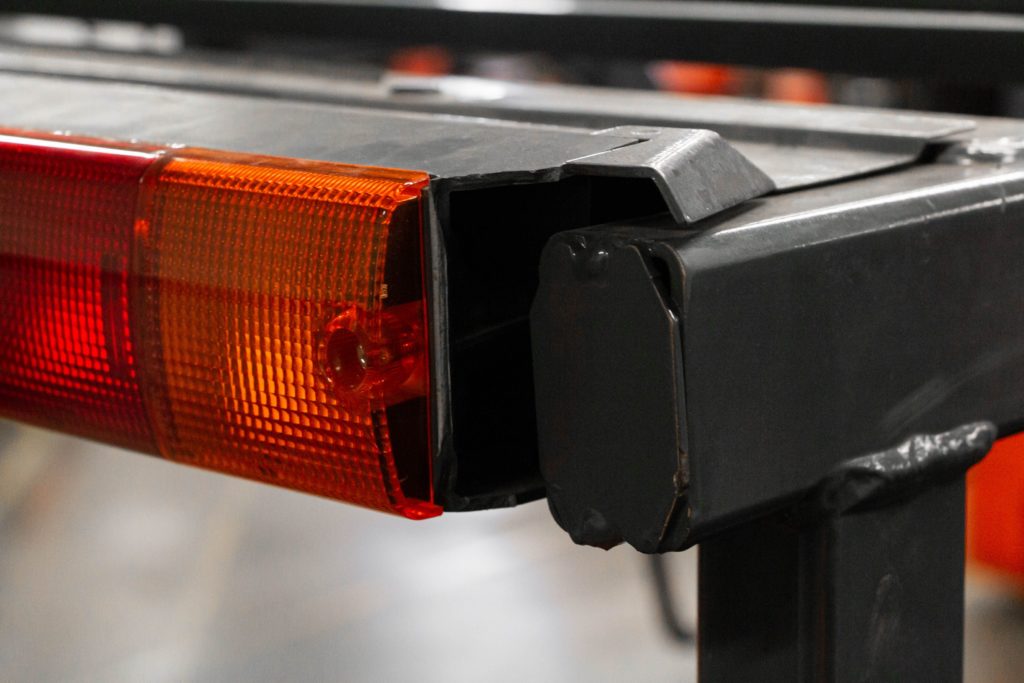

#3: Accessories: Horns, Lights & Travel Alarms

Whether for safety or operational purposes, or both, most forklifts these days have a combination of horns, travel alarms, and lights.

But as with anything, the more “things” you’ve got on your forklift, the more things can suddenly stop working.

Overall, we counted 864 accessory-related issues in 2019, making up 13.89% of all work orders surveyed.

Most Common Causes of Accessory Problems

Less Common Causes of Accessory Problems

-

Missing mounting hardware

-

Blown fuse

-

Malfunctioning or misaligned switch

How does a horn work?

A horn consists of a horn button, a contact plate, and pins.

When pressed, the components sandwich together, creating an electric circuit. The current passing through the circuit flows to the horn assembly, which makes the actual horn noise.

Average Costs Across All Accessory Repairs

What About Safety?

Since OSHA requires forklifts to have a working horn, it’s imperative that any horn issues be resolved immediately.

As far as headlights, tail lights and travel alarms are concerned, the application determines if they’re required.

For example, if the forklift is operating in low light areas, headlights will need to be fully functional.

What Can You Do to Prevent Accessory Issues?

Clean Horn Contacts and Pins

Horn contacts and pins can be cleaned at regular maintenance intervals. And greasing them with di-electric grease can help reduce metal-on-metal wear too.

But over time, these parts will degrade under repeated use until they make the horn inoperable.

The time to change the horn is before it wears out completely. Because OSHA will shut a forklift down for not having a properly-functioning horn:

“If the industrial truck is equipped with a horn as its warning device, then OSHA would consider the truck as being unsafe if the sound level of the horn has deteriorated to a level that can no longer be heard above the ambient noise in the workplace.”

– OSHA

Operator Training to Reduce Damage

A common root cause of light and travel alarm problems was operator-inflicted damage.

Since they are outside the overhead guard of the machine, the assemblies themselves are prone to be hit. Operator training can help to minimize these impact-related issues.

Broken Wires & Burnt-Out Bulbs

For issues like burnt-out bulbs and broken wires, prevention is more difficult. These things happen when they happen.

#4: Dead/No Start

Just like with your personal vehicle, sometimes forklifts just won’t start.

And also like in personal circumstances, most of the time a dead battery is the culprit.

But besides for dead batteries, we found a few other issues behind a dead forklift.

Overall, we counted 802 no start-related issues in 2019, making up 12.89% of all work orders surveyed.

Most Common Causes of No Start Problems

Less Common Causes of No Start Problems

-

Bad gear selector

-

Blown fuse

-

Tracker system fault

-

Bad seat belt/seat belt switch

-

No fuel

How do fuel regulators work?

The regulator is where liquid LP is turned into a gas. From there, it flows to the engine, powering the cylinders and driving the lift.

The reason regulators most commonly fail is because they get filled with gunk. The LP that flows into the regulator often comes along with rust and debris from inside the fuel tank.

Over time, that rust and debris gradually clog the regulator. Clogs in the regulator mean less fuel gets to the engine.

And when less fuel gets to the engine, the engine will either run poorly or not at all.

Average Costs Across All No Start Repairs

What About Safety?

As mentioned, any fuel system leaks need to be addressed immediately, as they present an emissions concern.

And though less commonly found as a cause, seat belt issues are a major safety concern. Any belts that are ripped, torn, or frayed must be replaced before the lift can be used.

What Can You Do to Prevent No Start Issues?

Install a Battery Disconnect Switch

Unfortunately, starter batteries tend to gradually lose their power over time. Thus, they tend to give little warning when they’re about to go completely dead.

That being said, a battery disconnect switch can help prevent dead batteries at least some of the time.

Many operations have a multitude of accessories to power, including headlights, safety lights (blues, reds, and strobes), operator fans, heater/coolers, computers/VMUs, etc.

So, installing a disconnect switch can help prevent these accessories from draining the battery after the unit is powered down.

Clean the Fuel System

Fuel system issues often can be prevented with regular maintenance and cleaning.

Bad Starters & Broken Wires

Issues like bad starters and broken wires are harder to prevent. They usually don’t give much of a warning before failing.

#5: Battery Problems

Electric lifts use batteries as their main power source. Internal combustion trucks, on the other hand, use them to power their starter motor.

Either way, batteries play a role in the operation of just about every piece of heavy equipment out there.

And overall, we counted 655 battery-related issues in 2019, making up 10.53% of all work orders surveyed.

Most Common Causes of Battery Problems

Less Common Causes of Battery Problems

-

Bad water filling system

-

Lifting eyes bent on the battery case

-

Battery leaking

Average Costs Across All Battery Repairs

What About Safety?

None of the issues listed above directly impact safety.

But since batteries are filled with acid, any leaks should be cleaned up immediately. Coating spills with baking soda will neutralize the acid and help prevent chemical injuries.

What Can You Do to Prevent Battery Issues?

Battery Maintenance

For starter batteries used in internal combustion forklifts, there’s not much you can do to prevent a dead battery issue.

Since these batteries are designed to discharge completely until they’re no good, your first sign of trouble is usually when it doesn’t start.

But for electric trucks, prevention comes down to two words: Battery maintenance.

Keep your batteries full of water. And wait until they’re fully charged before using them.

Do these two things and you can help extend the life of your battery.

#6: Running Rough

Spitting and sputtering, backfiring, and losing power: these are all issues that we classified as “running rough.”

The majority of work orders that we surveyed with this issue were for internal combustion trucks. But it was an ailment for some electrics as well (mainly the “losing power” issue).

Overall, we counted 466 rough running-related issues in 2019, making up 7.49% of all work orders surveyed.

Most Common Causes of Rough Running Problems

Less Common Causes of Rough Running Problems

Regulator vacuum hoses coming off or leaking

Bad alternator belt

Bad wiring harness & engine control unit (ECU)

Improperly-installed fuel line

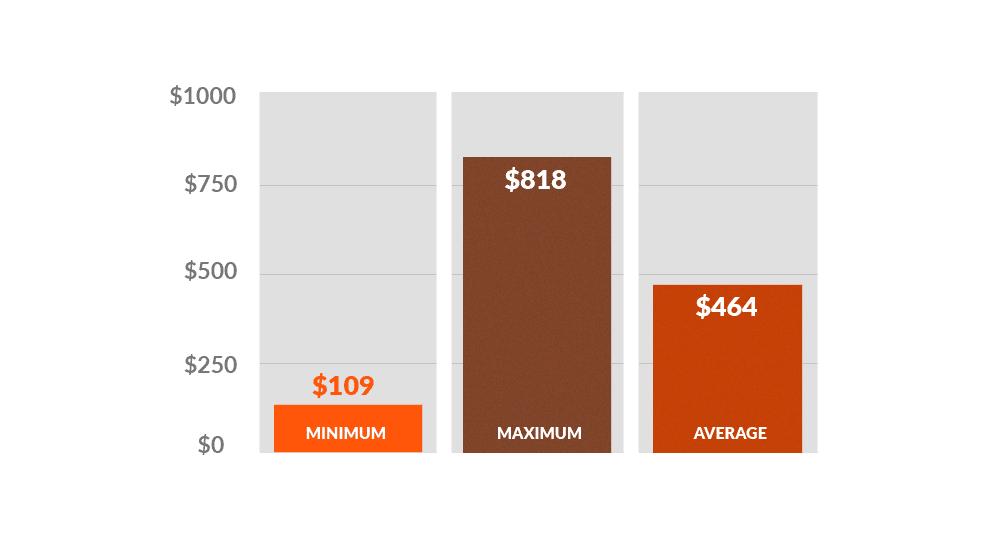

Average Costs Across All Rough Running Repairs

What About Safety?

Leaking regulators and loose vacuum hoses from the regulator are safety concerns for the same reason as mentioned before: emissions.

What Can You Do to Prevent Rough Running Issues?

Clean and Replace

Fuel systems tend to accumulate a lot of grit and grime during normal operation.

Therefore, regularly cleaning the throttle body and regulator, as well as replacing the fuel filter will help prevent rough running issues.

What is VF voltage?

VF voltage governs a forklift’s air-to-fuel mixture. It is a setting on the fuel regulator that is physically adjusted to keep the engine running properly.

If the VF voltage is off, the lift will have either too much fuel or too much air flowing to the engine. And if that’s the case, the engine will run rough or not at all.

Water and Charge

And given that battery issues were the second most common root cause, make sure to follow our advice from the last section: Keep them regularly watered and fully charged before using.

Limit Movement and Heat

As far as wires are concerned, the same advice from before applies here. Namely, wrap exposed wires with electrical tape. And try to limit movement and heat as best you can.

#7: Error Codes & Check Engine Lights

Just as in your personal vehicle, the dreaded check engine light is a problem for forklifts too.

Sometimes its presence follows the machine ceasing to operate. Other times it’s a nagging issue that doesn’t seem to present any symptoms along with it.

Overall, we counted 386 error code-related issues in 2019, making up 6.21% of all work orders surveyed.

Most Common Causes of Error Codes & Check Engine Lights

Less Common Causes of Error Codes & Check Engine Lights

-

Bad motor

-

Faulty control handle

-

Dirty motor brushes

Average Costs Across All Error Code & Check Engine Light Repairs

What About Safety?

Unless the code directly concerns a safety feature on the lift, error codes and check engine lights are usually more of an annoyance than a safety issue.

What Can You Do to Prevent Error Codes?

Remove Debris, Keep Cool, and Limit Movement

Like some of the other issues we’ve documented, check engine lights and error codes are hard to predict.

Problems with sensors, contactors, and switches, along with broken wires, tend to happen unexpectedly.

That said, doing the best you can to limit heat, debris, and movement can help to keep these components from malfunctioning.

Water and Charge

We know we sound like a broken record on this…

But it’s important enough to keep repeating: Make sure your batteries are properly watered, charged, and not put into use until completely charged.

Clean and Record

Keeping the fuel system clean – a common cause of several issues on this list – will help prevent the mystery error code from popping up on the display.

But if/when you do get one, keep a record of it. If you see 3 or 4 of the same code in a row, that’s a good indication that a switch is going bad.

#8: Electrical Problems: Buttons, Switches & Controls

We classified most issues that fell within the broad category of “electrical” here.

That includes buttons, switches, wiring and anything else that was not specific to another particular issue and didn’t directly affect the operation of the unit.

Overall, we counted 320 electrical issues in 2019, making up 5.14% of all work orders surveyed.

Most Common Causes of Electrical Problems

Less Common Causes of Electrical Problems

-

Debris

-

Bad spring

-

Blown fuses

Switches: How do they go wrong?

The biggest factors that cause switches to go bad are heat, excessive dryness, dirt or debris, and damage.

Some operating environments, like those with excess moisture, heat, cold, or debris, are harder on forklifts. As a result, they tend to have more issues with switches going bad.

Average Costs Across All Electrical Repairs

What About Safety?

If the electrical problem directly affects the operation of the unit, that could present a safety problem.

For example, consider a bad belly button switch on an electric pallet jack.

Because it’s designed to stop the unit from rolling back and hitting the operator, it would need to be replaced before using the unit.

What Can You Do to Prevent Electrical Issues?

Limit Heat, Moisture & Debris

As we’ve mentioned, electrical issues are by nature difficult to predict.

That being said, we did notice that some issues were caused by debris compromising sensitive equipment. So, frequently blowing out the unit can help to minimize some problems.

And keeping components clean, dry, and stationary, as well as covering any exposed wires can go a long way toward preventing electrical issues.

#9: Seats & Seat Belts

While not all forklifts have seats and seat belts, those that do must have them in proper working order.

Overall, we counted 265 seat and seat belt-related issues in 2019, making up 4.26% of all work orders surveyed.

Most Common Causes of Seat & Seat Belt Problems

Less Common Causes of Seat & Seat Belt Problems

We didn’t find any other root causes of seat or seat belt problems in our survey sample.

Average Costs Across All Seat & Seat Belt Repairs

What About Safety?

Seats and seat belts are the last lines of defense against operator injury in the event of a collision or tip over.

Therefore, seats must be securely bolted down. And seat belts must be free of rips, tears, or fraying.

Additionally, if the truck came with a seat switch or interlocking seat belt, they must be operable. Otherwise, the lift should be removed from service until they can be fixed.

What Can You Do to Prevent Seat & Seat Belt Issues?

No Sharp Objects

Seats and seat belts are considered wearable parts.

Repeatedly getting on and off the seat and buckling and unbuckling the seat belt will cause them to degrade over time.

Nevertheless, some things can help reduce that wear.

Ensuring that operators don’t have sharp objects, like keys or tools on their belt or person can help prevent seat tears.

Also, not placing objects that have sharp edges or protrusions on the seat while working can help too.

#10: Cooling System Problems

A general rule of forklifts is that the cooler you can keep the lift, the longer it will last.

Heat is the enemy of many forklift parts, especially the most critical (and expensive) ones, like the engine and transmission.

So, that’s why you should address cooling system issues as soon as they crop up.

Overall, we counted 249 cooling system-related issues in 2019, making up 4% of all work orders surveyed.

Most Common Causes of Cooling System Problems

Less Common Causes of Cooling System Problems

Fuel mixture out of adjustment

Bad regulator hose

Loose hose clamps

Cracked engine block

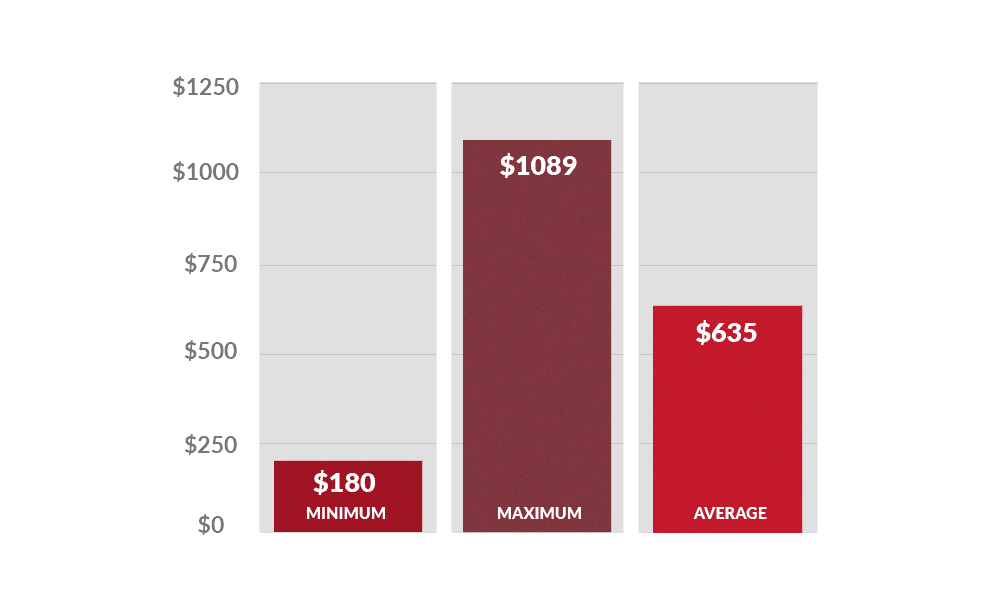

Average Costs Across All Cooling System Repairs

What About Safety?

None of the issues that we found directly affect safety.

What Can You Do to Prevent Cooling System Issues?

Clean with Air

In operations that handle material that produces debris, like paper mills and insulation manufacturers, radiators can become clogged quickly.

Blowing out the radiator with air at least once per shift can help to reduce overheating issues.

Other parts, like thermostats and water pumps, do degrade over time as they get hot. As a result, they are more difficult to catch before failure.

Conclusion

For those of you interested, here’s a link to our study methods.

Now it’s your turn:

What’s your #1 takeaway from this study?

Or maybe you have a question about the results?