Forklift tires come in various types and aren’t just black, round, and identical. They can be costly, prone to blowouts at inconvenient times, and lead to downtime. However, when maintained properly, forklift tires can help reduce fuel consumption, enhance workplace safety, and boost productivity.

Our comprehensive forklift tire guide – compiled by our tire specialists – will help you keep your forklift productive. It all starts with the tires.

We’ll cover everything from understanding basic tire types to getting the maximum life out of your tires. If you’re looking for cost-reduction recommendations, we have that, too.

Let’s get started! Click below to skip ahead:

Forklift Tires Types

Chances are, you have dealt with forklift tires before. However, if you are new to forklifts or want to learn more about different types of forklift tires, you are in the right place.

There are several types of forklift tires, each offering unique benefits and suited to specific work environments. Typically, forklifts are designed with a particular tire in mind.

Here’s a quick video overview:

If you want a more in-depth look at the characteristics of forklift tires, keep reading!

CUSHION/PRESS-ON TIRES

Cushion tires (press-on tires) are formed by molding solid rubber onto a steel band. The rubber can either be traction or smooth. These tires are durable and best suited for indoor or light outdoor use on smooth surfaces.

Read: The Advantages of Cushion Tire Forklifts

PNEUMATIC TIRES

Pneumatic tires are similar to car tires. They are made of traction rubber and filled with compressed air. Some companies fill their pneumatic tires with foam to avoid the upfront cost of solid pneumatic tires.

Although less costly, we do not recommend filling pneumatic tires with foam because it increases pressure on the casing, making it less sustainable. Pneumatic tires are great for indoor and outdoor applications when the work area is free of sharp objects.

SOLID PNEUMATIC FORKLIFT TIRES

Solid pneumatic forklift tires contain solid rubber, are durable, and can not be punctured or deflated. These qualities make them ideal for recycling centers, lumberyards, or other industries with sharp debris.

Read: What Are Pneumatic Tires and Why are They Used For Outdoor Applications

POLYURETHANE TIRES

Polyurethane tires, a type of press-on tire, are lightweight and more resistant to splitting, tearing, or chunking out under a load than rubber forklift tires. They combine good traction with low-rolling resistance. Polyurethane tires generally experience about twice the lifespan of rubber tires and should be used indoors only for light applications like warehousing.

These tires will wear from heavy usage in indoor environments, so consider cushion tires if your application requires high usage.

NON-MARKING FORKLIFT TIRES

Hydrated silicas and special additives form Non-marking tires, making them great for eliminating black floor marks. They are available for pneumatic, solid pneumatic, and cushion tires. These solid tires have a brief lifespan and tend to generate static electricity, requiring an anti-static strip on the forklift

Forklift Tire Comparison Charts

Each forklift tire type has its benefits and drawbacks. Maybe you’re wondering which is better: cushion vs. pneumatic tires. Well, that’ll hinge on how you’re using your forklift.

The ideal tire depends on its operational environment, how long you need the tires to last, and what you are willing to pay.

See the tire comparison charts below to get a snapshot of the advantages and disadvantages of each tire type.

PNEUMATIC VS. SOLID PNEUMATIC TIRES

| Tire Type | Indoor | Light Outdoor | Rough-Terrain Outdoor | Debris in Work Area | Lifespan | Durability | Cost |

|---|---|---|---|---|---|---|---|

| Pneumatic | ✓ | ✓ | No | No | Medium | Medium | $ |

| Solid Pneumatic | No | No | ✓ | ✓ | Long | High | $$ |

CUSHION VS. POLYURETHANE TIRES

| Tire Type | Indoor | Light Outdoor | Rough-Terrain Outdoor | Debris in Work Area | Lifespan | Durability | Cost |

|---|---|---|---|---|---|---|---|

| Cushion | ✓ | ✓ | No | No | Medium | High | $ |

| Polyurethane | ✓ | No | No | No | Long | High | $$ |

What Are Forklift Tires Made Of?

Forklift tires are crafted from polyurethane resins or rubber and may incorporate carbon black or hydrated silicas. Certain forklift tires even contain steel wires. The content of a forklift varies depending on your tire type. Fortunately, We have dissected this information to help clarify what your forklift tire is made of.

WHAT ARE PRESS-ON TIRES MADE OF?

Cushion press-on tires are manufactured using a solid rubber molded to a steel band. Unless they are non-marking they will contain carbon black, which causes the black marks on floors. Meanwhile, polyurethane press-on tires are made of – you guessed it – polyurethane resins along with synthetics and synthetic blends.

WHAT ARE SOLID PNEUMATIC TIRES MADE OF?

Solid pneumatic tires are tires designed to prioritize durability. They begin with steel bead wires on the tire’s shoulder and continue with a hard rubber compound base. Next comes the nylon carcass, which consists of a section of steel belts. If these solid airless tires were to get speared, the nylon carcass protects against damage.

Also, there is a soft rubber core to aid operator comfort and reduce operator fatigue. Finally, the tread – the wearable part of the tire – is made of an abrasion-resistant rubber compound.

WHAT ARE NON-MARKING TIRES MADE OF?

Non-marking variations are made of a blend of natural rubber with hydrated silicas and special additives with carbon black removed to eliminate marks on floors.

How To Read Forklift Tires Sizes

First, let’s start with the basics. Whether you are the forklift operator or the plant manager. A basic understanding of forklift tires is essential to staying productive and efficient. The basic components of your forklift tires are:

- Sidewall – shows important tire information like the tire brand, size, tire type, and wear line.

- Tread – Raised rubber that comes in contact with the ground.

- Rim – Metal portion of the wheel that holds the tire in place.

READING FORKLIFT TIRES SIZES

You can find your forklift tire size on the sidewall of the tire. If you do not see the size, check the operator’s manual or call your local forklift dealer with the model. They should be able to tell you the tire size for your model forklift.

Be aware that the tire size may be noted differently depending on the type of forklift tire you are dealing with.

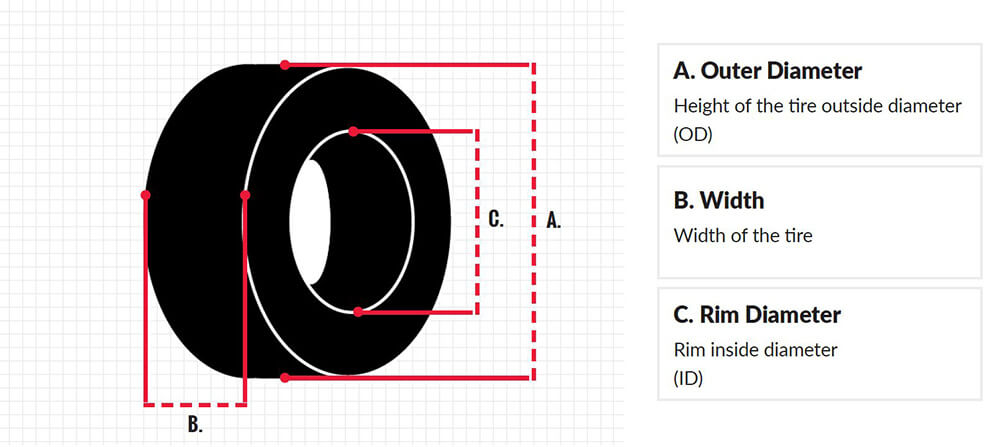

For Press-on tires, sizes are noted as the Outer Diameter x Width x Rim Diameter. An example would be 16 x 6 x 10.5.

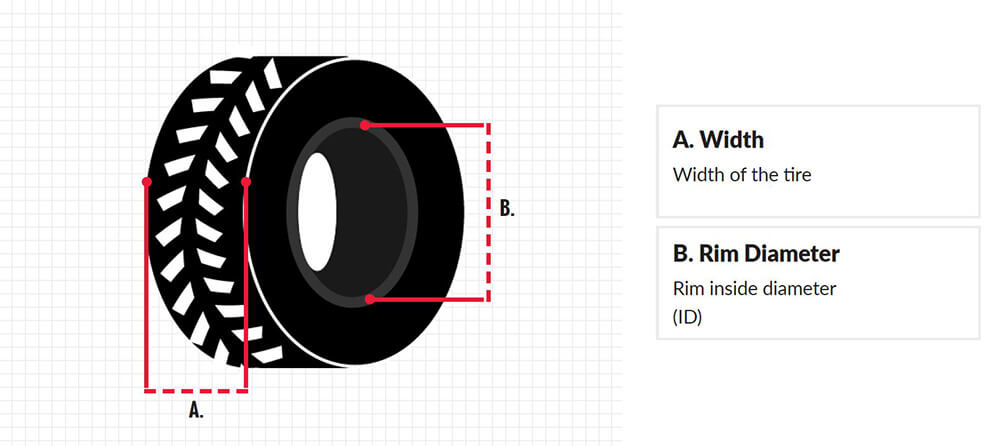

Pneumatic or solid pneumatic tire sizes are noted as the Width x Rim Diameter. An example would look like: 6.50 x 10.

Generally, your forklift will have a recommended size, but you can purchase a different size, within reason, depending on your preference and application. Check your forklift’s manual and with your local dealer for appropriate tire sizes.

HOW TO MEASURE FORKLIFT TIRES

You can measure your forklift tire size by using your average tape measure.

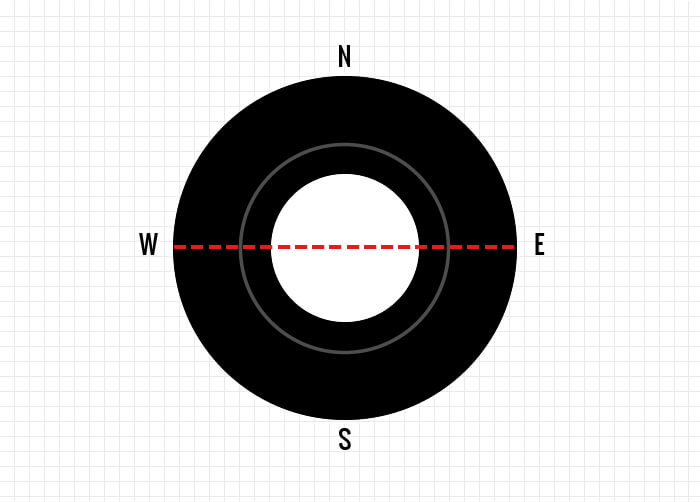

- Measure the outer diameter, and picture the tire as a compass with the north at the top of the tire. Make sure you’re placing the tape measure at the center of the tire and run the tape measure east to west.

- Measure the rim diameter, stay in the center of the tire, and only extend the tape measure to each edge of the rim.

- Measure the width of the tire, position the tape measure on the part of the tire that would make contact with the ground, and run the tape measure from edge to edge.

Remember, for press-on tires, you need to measure the outer diameter, the width of the tire, and the rim diameter. To measure pneumatics or solid pneumatic tires, measure the width and the rim size.

How To Choose The Right Forklift Tires

Consider your application, forklift, and work environment when choosing a tire type.

At Conger, often we are asked: “Can you put pneumatic tires on a cushion tire forklift?” Your forklift’s wheels and frame are generally designed for a specific tire type (usually pneumatic or cushion), so it is best to verify with your local dealer and your forklift manual if you want to go with a different tire type than the recommended one.

Often, you can switch from smooth cushion to traction cushion or pneumatic to solid pneumatic tires, but you can rarely go from a cushion tire to a pneumatic tire and vice versa.

When it comes time to replace the tires, ensure both sides of the forklift are the same tire type. The front and back tires can differ, but both front and back tires must be the same type.

For example, you can not have a smooth cushion tire on the front right and a traction cushion tire on the front left. Instead, you’d have two smooth cushion tires in the front and two traction cushion tires in the back.

TIRE RECOMMENDATIONS FOR YOUR APPLICATION

Different applications require different forklifts and, therefore tire types. We have outlined some applications below with our recommendations. Check with your forklift dealer to confirm that our recommendations suit your situation.

Indoor Applications

Indoor applications with no debris on the floor surface are best suited for cushion tires. In this environment, cushion tires last longer and are more maneuverable, with improved traction.

OUTDOOR & ROUGH TERRAIN APPLICATIONS

Outdoor and rough-terrain applications generally use pneumatic or solid pneumatic tires since they offer better traction and increased stability on uneven, loose terrain.

WAREHOUSE APPLICATIONS

Warehousing and other applications that frequently use order pickers will often use polyurethane tires. Order pickers primarily utilize polyurethane tires because they can enhance the machine’s expected battery life and offer added stability and traction.

COLD ENVIRONMENTS

Cold environments or environments with consistently wet floors typically use polyurethane tires with micro grips (small, raised dots) or razer sipes (narrow, diagonal grooves) since they provide increased traction and braking ability.

OIL SPILLS

If your environment experiences standing oil or consistent oil spills, consider using polyurethane tires to resist the oil and experience less breakdown.

SENSITIVE APPLICATIONS

Sensitive applications, such as food, paper, or printing, require non-marking tires since standard tires contain carbon black, which creates a fine dust particle during use that can cause cross-contamination issues.

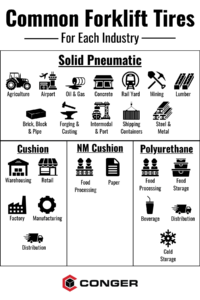

FORKLIFT TIRE STANDARDS FOR YOUR INDUSTRY

Your industry may also be a deciding factor. Check the industries below to see which tire type is commonly used in that application.

These industry standards may change depending on the specific work environment and the application. Check with your forklift tire dealer to confirm the best option for your situation.

For professional-grade forklift tire service, from check-ups to repairs, consider giving our seasoned pros at Conger Industries a shout. With locations in Green Bay, Neenah, Wausau, Richfield, and Madison, we are conveniently situated to serve your material handling needs. Explore our services further by visiting our page.

How Long Should Forklift Tires Last?

How long forklift tires last depends on five factors:

- Usage

- Tire Type

- Floor Conditions

- Operating Conditions

- Operator Behavior

Let’s go through each one.

USAGE

The hours you put on your forklift tires make a huge difference.

If you use your forklift for 10 hours a week, the tires will likely last longer than if you were using it 40 hours a week.

TIRE TYPE

Some tire types are naturally more prone to wear and tear than others.

Pneumatic tires typically wear out faster than solid pneumatics. Plus, they can be punctured, causing a flat tire which requires a patch or replacement.

Be sure to carefully monitor the air pressure to get the most out of your pneumatic tires. Low air pressure equals more contact with the floor surface, leading to more tire wear.

In contrast, solid pneumatic tires have a longer life than pneumatics as they are extremely durable and resilient tires that resists wear and tear.

When it comes to press-on tires, polyurethane tires typically see up to two times the life of cushion tires.

FLOOR CONDITIONS

The abrasiveness of the ground surface can limit your tires’ life. The best case scenario for a long forklift tire life is sealed concrete or blacktop.

Surfaces with lots of debris are going to shorten your tire life too.

Running over debris isn’t a good idea. Not only does it damage your tires, but it’s not safe for forklift operation and it can be uncomfortable for the operator too.

Avoiding debris can be challenging in environments like recycling centers and lumber yards. While solid pneumatic tires are durable and well-suited for these conditions, it is still advisable to steer clear of debris whenever possible.

OPERATING CONDITIONS

Your general work environment and operating conditions can shorten the life of your forklift tires.

Something as simple as humidity can be an issue. Humid environments can make the floor sweat, causing the tires to spin more and wear them out.

It’s not just the environmental conditions that can affect your tire conditions but also the load you carry.

While you do not want to overload the lift truck, running the forklift without a load shortens your tire life. Without a load on the forks, the counterweight presses down on the steer tires, which causes them to wear more quickly

OPERATOR BEHAVIOR

Your forklift operator’s driving habits and abilities affect the life of your tires.

Spinning the tires, quick starts and stops, excessive speed, and sharp cornering all reduce the life of your forklift tires. If you’re zipping around the warehouse, taking tight turns, and stopping abruptly, it’ll take a toll on your airless forklift tires.

Getting The Most Out Of Your Forklift Tires

A tire in good condition will increase your forklift’s efficiency, improve productivity, and reduce operator fatigue. Additionally, maximizing tire performance means a better bottom line and a safer workplace.

So, how can you keep your tires in good condition? It starts with operator education but also depends on your tire type and environment.

OPERATOR EDUCATION

Poor operator habits are an influential cause of reduced tire life. These basic reminders for operators can increase safety in the workplace and improve the life of the tire.

Operators should not:

- Spin the tires.

- Overload the vehicle.

- Run over debris.

Operators should avoid:

- Quickstarts.

- Quick stops.

- Excessive speed.

- Sharp, aggressive cornering.

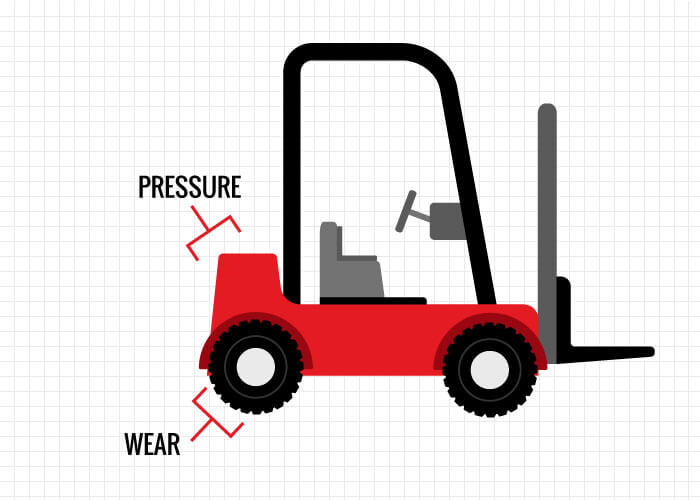

AIR PRESSURE

You should check the air pressure on your pneumatic tires before each use. However, if that is not possible, try to check daily. You can find the recommended PSI on the sidewall of the tire.

Check your tire air pressure often because air pressure fluctuates with increasing and decreasing temperatures. Higher temperatures increase air pressure, and lower temperatures decrease air pressure. This issue is a year-round responsibility, not just a seasonal concern since temperatures can vary significantly depending on your climate.

Why does air pressure matter? Under-inflated tires lead to poor traction, which can cause accidents. Over-inflated tires can cause a blowout, which causes downtime and profit loss. Checking tire air pressure is an easy way to avoid more serious problems that reduce productivity.

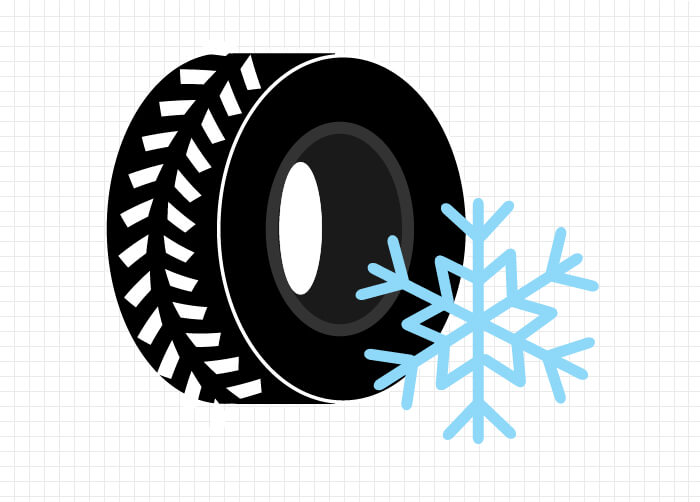

WINTER RECOMMENDATIONS FOR FORKLIFT TIRES

Winter brings challenges when it comes to outdoor forklift operation. The snow and ice that come with the colder temperatures cause slippery conditions and reduced traction. Often, forklift tire chains are the primary defense for reduced traction, but they aren’t your only option.

Reduced traction is a major concern as snow and ice accumulate. You can get stuck easier than you might expect. When compared with a personal vehicle, a forklift is much heavier – even without a load – which makes sufficient friction even more essential when operating your forklift in slippery conditions.

The best way to get better traction is to increase the surface area connecting with the ground.

We recommend you use pneumatic tires instead of solid pneumatic. Pneumatic tires have more flex than solid pneumatics which increases the surface area contacting the ground and improves traction.

This recommendation may seem obvious, but make sure your tires’ tread has not worn away. Your tires won’t be able to grip the ground without it, and if the tread has completely worn away, it’s time to replace the tires.

Tire Chains

While forklift tire chains are not your only option, they are great at defending against slippery conditions and poor traction. Tire chains are available for both pneumatic and solid pneumatic tires.

Use them only when the snow and ice make it dangerous to operate your forklift or when conditions cause inefficiency or reduced productivity.

Studs can be screwed into the tread of your solid pneumatic tires to help alleviate icy conditions. We recommend using studs with a solid carbide tip which are stronger and more durable.

Don’t worry, after removing the studs the tire won’t be damaged and you can re-use the studs at a later date.

Using salt is a method that will not affect your tires, but it can cause the metal components in your forklift to rust. Instead of pure salt, we recommend you use a sand-salt mixture.

When To Replace Your Forklift Tires

Knowing when to replace your forklift tires is crucial. Neglecting this can result in reduced fuel efficiency, but more critically, it can lead to operator fatigue, increasing the risk of errors and endangering others in the vicinity. Moreover extensive damage can also be done to your equipment if the tires aren’t replaced in time.

Replacing your forklift tires at the right time is crucial. However, how do you know when they need replacing? Forklift tires – like automotive tires – don’t have a specific time frame for replacement. Instead, you replace your forklift tires when they are worn or damaged.

Here’s a quick video overview on checking your tires for wear and damage. For more in-depth information on when to replace your tires, keep reading!

CHECKING YOUR TIRES FOR WEAR & DAMAGE

Regularly inspect your forklift tires to check for wear and damage. Your operators should include this in their pre-operation inspections. They will be able to catch issues before they become problems.

There are a few areas to check to determine if your forklift tire needs a replacement:

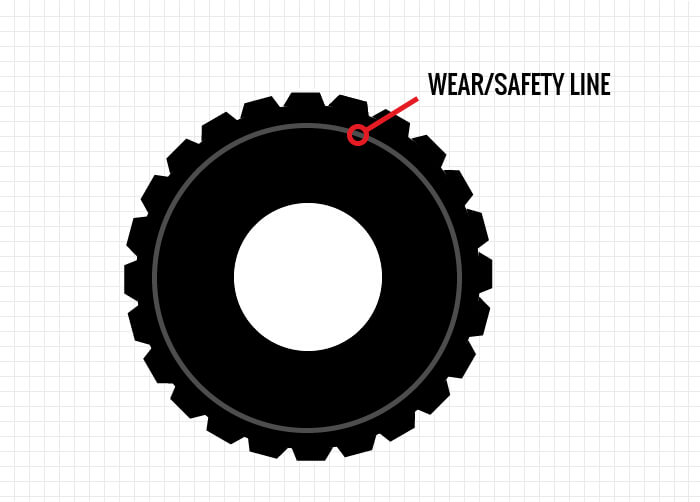

Wear Line or Safety Line – Many tire manufacturers provide a wear line on the tire. It is time to replace the tire once the rubber is worn to that line.

USAGE

Lettering -Examining the tire sidewall is another way to check for tire wear. Once the tire reaches the top of the numbering or lettering on the sidewall, the tire needs replacement.

Tread – Similar to a car tire, visually check the tread height on the tire to determine if the tire needs replacing. If the tire is balding, replace it.

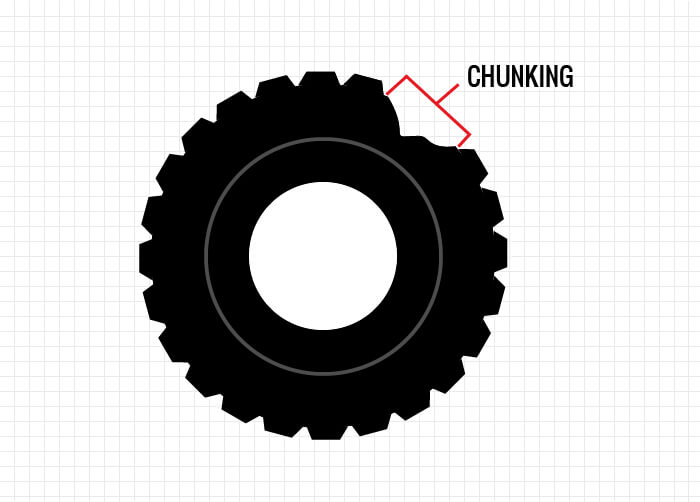

Chunking– Chunking occurs when the tires repeatedly run over debris and cause large pieces to fall off the tire. A chunking tire can cause a bumpy ride for the operator, increasing fatigue and leading to the potential for mistakes. Damage to the load or product may also occur from chunking.

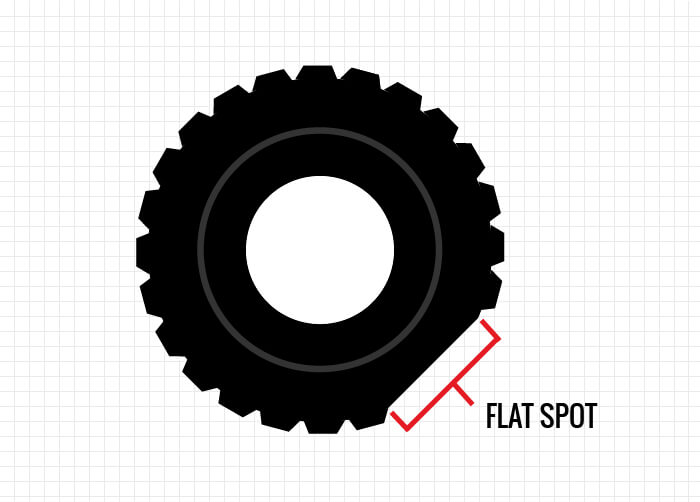

Flat Spots – Sometimes flat spots can appear on the tire caused by spin or aggressive braking. This issue creates an uneven and uncomfortable experience for the operator. You can prevent flat spots by training operators on appropriate speeds

Radial Cracking – Radial cracking can occur when heat builds up within the tire. Cracking is often a result of overloading the machine. If you consistently see radial cracking on your pneumatic or cushion tires, consider using larger or wider tires to spread the weight of the load over more area. Heat buildup is also caused by traveling long distances with no weight on the forks. In these situations, the counterweight rests on the steer tires instead of being distributed.

TIRE REPLACEMENT BASED ON YOUR TIRE TYPE

Wear and damage can vary depending on the type of tires you have. There are many ways to check if your tires need replacement based on their specific type. Let’s start with cushion tires.

There are a few ways to check if you need to replace your cushion tires.

One of the primary ways is the two-inch rule. If the tire has lost two inches or more from its original height, it needs replacement. If you do not know the tire’s original height or outer diameter, it should be noted on the sidewall of the tire.

When measuring the tire’s wear, picture it as a compass, with the top of the tire as north. Take measurements across the center of the tire from west to east. If you take measurements from north to south, they may end up skewed because the tire flattens under the weight of the forklift.

Keep in mind that the two-inch rule only works on cushion tires.

CUSHION TIRE WEAR CHART

Check the outer diameter (OD) and rim inside diameter (ID) of your cushion tire (found on the sidewall). If your tire’s outer diameter is around the “Old Tire OD” for tire size, it’s time to replace it.

| New Tire OD | New Tire ID | Old Tire OD |

|---|---|---|

| 8 | 4 – 1/2 | 6.50 |

| 8 – 1/4 | 4 | 6.5 |

| 9 | 5 | 7.25 |

| 10 | 5 | 7.75 |

| 10 | 6 | 8.25 |

| 10 | 6 – 1/4 | 8.38 |

| 10 | 6 – 1/2 | 8.50 |

| 10 – 1/2 | 6 – 1/2 | 8.75 |

| 12 | 8 | 10.25 |

| 13 | 8 | 10.75 |

| 13 – 1/2 | 8 | 11.00 |

| 14 | 8 | 11.25 |

| 14 | 10 | 12.28 |

| 15 | 11 – 1/4 | 13.41 |

| 15 – 1/2 | 10 | 13.03 |

| 16 | 10 – 1/2 | 13.53 |

| 16 | 12 | 14.28 |

| 16 | 4 – 1/8 | 14.34 |

| 16 – 1/4 | 11 – 1/4 | 14.03 |

| 17 | 12 – 1/8 | 14.84 |

| 18 | 12 – 1/8 | 15.34 |

| 18 | 14 | 16.28 |

| 20 | 15 | 17.78 |

| 20 | 16 | 18.28 |

| 21 | 15 | 18.28 |

| 22 | 16 | 19.28 |

| 22 | 17 – 3/4 | 20.16 |

| 23 – 3/4 | 17 – 3/4 | 21.03 |

| 24 | 20 | 22.30 |

| 26 | 20 | 23.30 |

| 27 – 3/4 | 26 – 1/2 | 25.93 |

| 28 | 22 | 25.30 |

| 36 | 30 | 33.36 |

Check for damage

Bond failures occur when the rubber has separated from the metal band. If you can stick a screwdriver or a knife into the separated area, it is time to replace the tire.

Visually inspect the tire tread

For traction cushion tires, there is no definitive tool to determine tread wear, so a visual check is necessary. If 25-30% of the tread is worn down, the tire needs a replacement.

For solid pneumatic tires, if there are no signs of damage, assess the amount of wear. When 75-80% of the tread is worn, the tires should be replaced. Although this rule applies in most cases, you should also consider your operators and the specific application.

Finally, let’s go over wear for polyurethane tires. One of the more common signs of wear on poly tires is radial cracking. It occurs when heat builds up within the tire material and escapes through the exterior of the tire. Polyurethane tires with radial cracking are ready for replacement.

BENEFITS OF REPLACING YOUR FORKLIFT TIRES

Newly replaced tires benefit the forklift operator and company. Some of these benefits include:

- Reduced fuel consumption

- Maximized efficiency

- Increased traction

Additionally, new tires will reduce shock, creating a better ride for the operator and reducing operator fatigue. It can also lower maintenance costs. Similar to a bicycle in a higher gear, newly replaced tires can cover the same distance in fewer rotations. Resulting in less wear on drivetrain components.

Cost Reduction Recommendations

Replacing your tires can be costly. Though it is a necessary expense, you can reduce your costs in a few ways.

CHOOSE SMOOTH OVER TRACTION

When possible, use smooth cushion tires rather than traction tires. This switch can increase the consumable rubber by 7-12%. Plus, you will experience increased traction if water or any other liquid debris is not present.

GET HIGH RUBBER RESILIENCE TIRES

Tires with high rubber resilience offer the advantage of low rolling resistance. Switching to these tires can typically reduce fuel consumption in LP gas forklifts by up to 15% and extend the working hours between charges for electrics.

UPSIZE

Upsizing your tires can provide several benefits:

- Extended tire lifespan

- Enhanced grip

- Improved stability

- Enhanced shock absorption

You will also notice that the tires run at a lower temperature. Your load-carrying capacity will increase as the weight spreads out along the tire. On average, increasing tire size by one inch translates to 800 pounds in additional load-carrying capacity.

REPLACE PNEUMATICS WITH SOLID PNEUMATICS

We often recommend switching from pneumatic to solid pneumatic tires. This issue does not necessarily apply to winter conditions. However, in many situations, replacing your pneumatic tires with solid pneumatic tires can:

- Improve tire life by two to three times

- Increase stability

- Reduce downtime (no flats)

Before making these changes, verify with your tire dealer that your equipment, facility, and application will see these benefits.

From tire components and choosing your forklift tires to getting the most out of your tires and reducing costs, you should now be a forklift tire expert.

![Forklift Tires – The Ultimate Guide [Reading Sizes & Comparing Types]](https://www.conger.com/wp-content/uploads/2018/05/Forklift-Tires-Featured-Image.png)