Model Numbers: 100G-BOS-4A-0005 | 140G-BOS | 25D-BAB | 35D-BAB | 50D-BAB | 25D-BAS | 35D-BAS | 50D-BAS | 14J-BOB-2A | 18J-BOB-2A | 22J-BOB-2A | 22J-BOB-3A | 26J-BOB-3A | 14J-BOS-2A | 18J-BOS-2A | 22J-BOS-2A | 22J-BOS-3A | 26J-BOS-3A

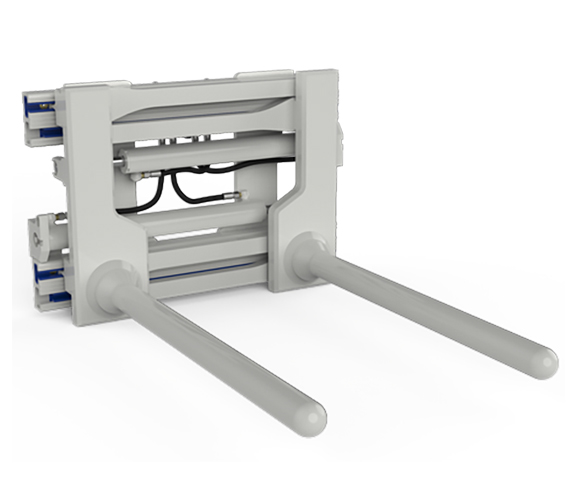

Cascade J-Series Bar Arm Attachments

- 2,500 – 7,715 lb. Capacity

- II – IV Mounting Class

- 8.2 – 86.6 in. Opening Range

- 26.4 – 40 in. Hook Spread

Documents

Cascade Bar Arm Attachments are specially designed for the textile industry, providing safe and efficient handling of cloth rolls like towels, linens, and denim. These attachments can cradle single or multiple rolls or enter the core for secure transport. With round, smooth bar arms that prevent tearing, snagging, or puncturing, they offer a safer alternative to standard forks for delicate textile materials.

J-Series Features:

- Clamp and backhand protection

- Flow divider for equal arm movement

- Top-mounted hydraulic cartridges and test port for ease of access and adjustment

- Sideshift circuit relief optimizes sideshift speed and performance

- Center mounted hardened replaceable frame wear segment

- High strength steel frame

- Lubrication-free, full length UHMW bearings

- High strength steel castings

- Maximum clamp force for secure handling

- Thin arm profile for manipulating tight loads between stacks

- Rubber-faced aluminum contact pads for secure handling of loads

G-Series Features:

- Lube-free, full-width lip over UHMW bearings for long life

- Rounded bar end prevents product damage

- Top-mounted cartridges and test ports in valve for ease of service

- Industry leading visibility

- Bolt-on, frame wearing strips with front facing hardware provides maximum protection and easy replacement

- High-strength, hot extruded steel frame

- Carriage centering key for precise and secure mounting

- Smooth high-speed performance

- Rugged lightweight construction for maximum capacity retention

- Flow divider for equal arm movement

D-Series Features:

- Proven, durable arm and aluminum frame construction ensuring long useful life of the clamp

- Superior arm-slide material and design for extended bearing life

- Rounded bar nose prevents product damage

- Easily accessible valve body and cartridge check valves

- Regenerative hydraulic valving for optimal arm speed

- Low profile frame for maximum visibility

J-Series Advantages:

- True centering key for precise and secure mounting

- Standard adjustable pressure relief in clamp and side shift functions

- Optional hardened full width wear strip protects frame from damage when scraping on the ground

- No maintenance bearings with 10,000 hour warranty

- Optional cylinder bumper protects the hydraulic lines and cylinders from impact and debris

G-Series Advantages:

- Carriage centering key for precise and secure mounting

- Easy access hydraulic valve for serviceability

- Hardened steel wear strips protects frame from damage

- Lube-free, full-width lip over UHMW bearings provide superior durability and service life

- Optional cylinder bumper protects the hydraulic lines and cylinders from impact and debris

D-Series Advantages:

- Proven, durable arm and aluminum frame construction ensuring long useful life of the clamp

- Superior arm-slide material and design for extended bearing life

- Rounded bar nose prevents product damage

- Easily accessible valve body and cartridge check valves

- Regenerative hydraulic valving for optimal arm speed

- Low profile frame for maximum visibility

J-Series Options:

- Special frame widths and opening ranges

- High pressure and low pressure hydraulics systems

- Basic and side shifting models

- Other arm dimensions

- Independent arm control

- Regeneration valve (faster opening speed for low flow electric trucks)

- External side shifter mounting

- Full width bolt-on wear strips to protect the frame

- Valve guard

- Factory installed load backrest

- Bumper/Cylinder cover

- Quick Disconnect Mounting Kit

G-Series Options:

- Custom bar arm lengths, diameters and tip configurations

- Centered or insert bar arm mounting locations

- Various mounting options available

- Quick-disconnect lower hooks

- Custom frame widths

- Custom opening ranges

- Cylinder protection bumper

- Steel hydraulic valve guard

- Consult Cascade for customized solutions to fit your application

D-Series Options:

- Custom bar arm diameters, lengths and tip configurations

- Various mounting classes available

- Quick-disconnect mounting

- Custom opening ranges

- Independent arm control

- Textile Industry