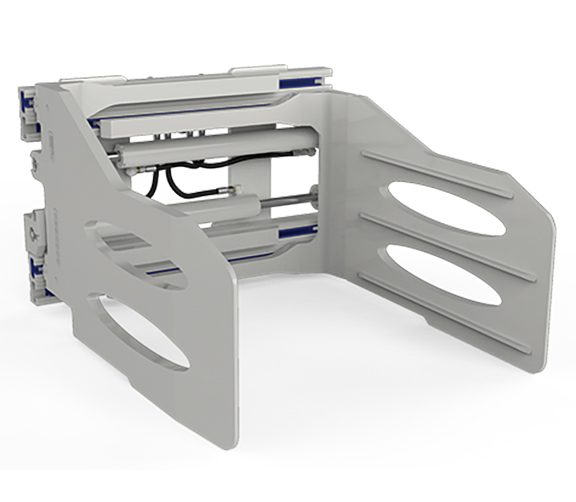

Engineered for high-volume, damage-free handling, the Cascade J-Series Pulp Bale Clamps are perfect for secure handling of pulp bales and unitized pulp in demanding environments like stevedoring, mills, warehousing, shipboard, and transport operations. These clamps provide a reliable, gentle grip to prevent damage while maintaining secure control, ensuring that high-value loads are handled efficiently and safely. Ideal for intensive applications, the J-Series Pulp Bale Clamps support productivity and product integrity, making them essential for high-demand pulp handling tasks.

Model Numbers: 50D-PBS | 70D-PBS | 70F-PBS | 170G-PBS | 120G-PBS | 140G-PBS | 100D-PBS | 140D-PBS | 170D-PBS | 200D-PBS | 220D-PBS | 14J-BCS-2A | 18J-BCS-2A | 22J-BCS-2A | 22J-BCS-3A | 26J-BCS-2A | 26J-BCS-3A | 14J-BCR-2A | 18J-BCR-2A | 22J-BCR-2A | 22J-BCR-3A | 26J-BCR-2A | 26J-BCR-3A | 26J-PBS-3A