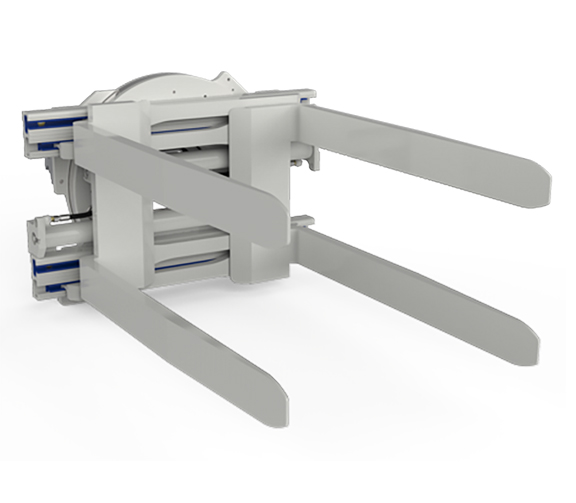

The Cascade J-Series Turnaload is a dual-purpose attachment designed for efficient clamp and pallet handling. Ideal for shipping, receiving, and order-picking tasks, it enables seamless handling of both palletized loads and palletless items like boxes, crates, cartons, and scrap bales. Built for versatility, the Turnaload allows operators to switch between functions effortlessly, making it an essential tool for streamlining operations and boosting productivity across diverse material handling applications.

Model Numbers: 35D-TAL | 50D-TAL | 70D-TAL | 18j-TAL-2A-0220 | 26J-TAL-3A-0230