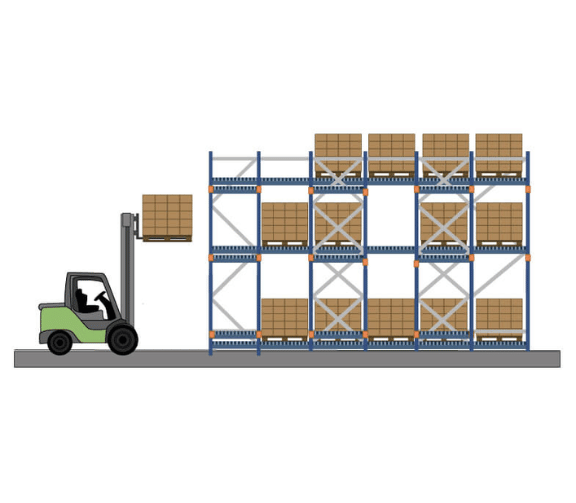

In a drive-thru racking system, forklifts enter the racking’s interior from either of 2 access points on each side of the racking.

When loading, lift trucks pass through the rack bay, placing loads on supporting rails from one side, and then exiting in the same direction.

When unloading, operators can enter the racking from either side to retrieve the pallet.

This racking system is best for First-In, First-Out (FIFO) inventory management and operations with high volumes and few SKUs.