Showing 1–20 of 191 resultsSorted by latest

-

New

New2020 Toyota 8FBE15U (E-012265)

$21,400.00 View Details -

New

New2020 Toyota 8FBE15U (E-012266)

$21,400.00 View Details -

New

New2019 Toyota 8FBE18U (E-042375)

$15,900.00 View Details -

New

New2020 Toyota 8FBE18U (E-042451)

$20,400.00 View Details -

New

New2020 Toyota 8FBE18U (E-042452)

$20,400.00 View Details -

New

New2019 Toyota 8FBE15U (E-010338)

$24,400.00 View Details -

New

New2022 Toyota 8FBE20U (E-018678)

$25,400.00 View Details -

New

New2019 Toyota 8FGC35U-BCS (E-012222)

$30,400.00 View Details -

Combi Order Picker

View Details -

Combi Side Loading Forklift

View Details -

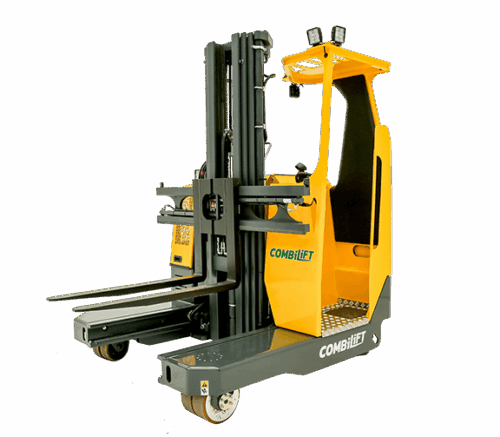

Combi Multi Directional Stand on Forklift

View Details -

Combi Two Directional Sideloader

View Details -

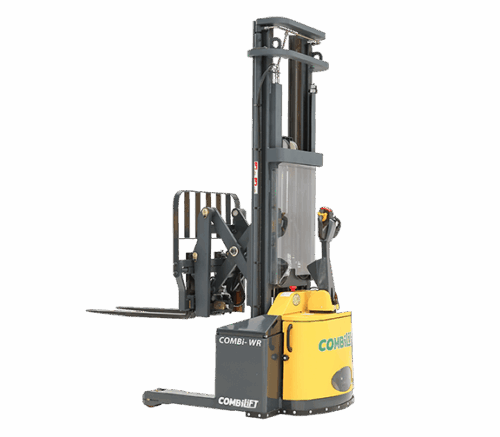

Combi 4-Way Pedestrian Reach Stacker

View Details -

Combi Pedestrian Reach Stacker

View Details -

Combi Dynamic 360° Multi-Directional Forklift

View Details -

Combi CUBE Counter Balance Forklift

View Details -

Combi Multi Directional Forklift

View Details -

2020 Toyota 8HBW23 (E-012637)

$4,900.00 View Details -

2012 Toyota 8FGCU25 (L754)

$18,900.00 View Details -

2019 Toyota 8FGCU30 (E-038968)

$22,400.00 View Details

Forklift Sales Informational Resources

Buying a Forklift: The Ultimate Guide to Making the Right Decision

New & Used Forklift Prices: What You Can Expect to Pay

Frequently Asked Questions of Used Forklift Sales

What used forklift brands do you sell?

We are an authorized dealer for Toyota forklifts, Clark forklifts, Combilift forklifts, Flexi forklifts and Tora-Max equipment, so many of our used forklifts for sale are from these popular brands. However, from time to time we have inventory from lift truck brands such as Hyster, Yale, Mitsubishi, Cat, Linde, Nissan, Komatsu, and many others.

What used forklift capacity ranges do you have for sale?

Typical forklift capacities range from 3,000 lbs up to more than 70,000 lbs, but the typical range for our used forklift fleet is from 5,000 lbs. to 8,000 lbs. Use the filters on this page to see if we have any available for sale in the capacity range you are looking for.

What is a fair value price for a used forklift?

The fair value of a forklift is influenced by factors such as its brand, capacity, fuel type (electric, diesel, or propane), and overall condition. A new standard forklift typically costs between $20,000+, whereas used models are usually priced lower than a new one depending on the same factors listed prior.

Is there a Kelley Blue Book for used forklifts?

Assessing used forklift prices is not as straightforward as buying a used car. Unfortunately, there is not a Kelley Blue Book available to determine the value of a pre-owned forklift. The number of hours and age of the forklift are the most significant factors that affect how much a used forklift is worth.

Do you provide a warranty for your used lift trucks?

Yes, most of our used forklifts come with a 60-day parts and labor warranty.

Frequently Asked Questions of New Forklift Sales

Do you offer financing options for new forklift purchases?Yes, we can help to finance your purchase through our vetted vendors.

Is it better to lease or buy a forklift?

Whether to buy or lease a new forklift depends on several factors, including your business needs, financial situation, and long-term plans. Our experts can help guide you through this decision and the options available to you.

Do new forklifts hold their value?

New forklifts do not typically hold their value as well as other types of equipment, like cars or certain types of machinery. This is due to factors such as depreciation, wear and tear, market demand, to name a few. Toyota forklifts tend to be worth more on the used market.