Do you have questions about what is a pallet jack? Well, you have landed in the right place!

In this article, we will explore everything you need to know about them, including:

- What pallet jacks are

- The different types of pallet jacks

- How to use a pallet jack

- And much more!

Let’s dive in!

What Is a Pallet Jack?

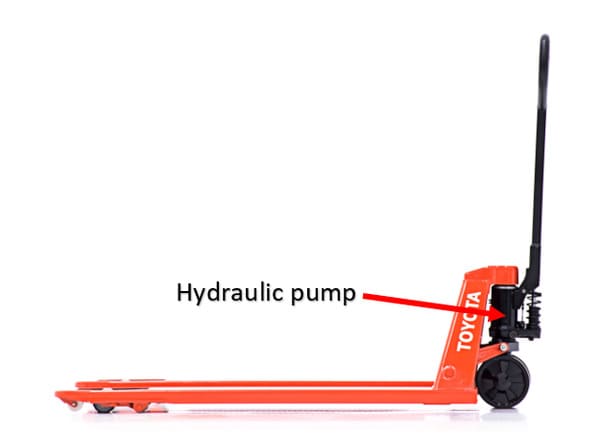

A pallet jack, also known as a ‘pallet truck,’ is crucial for many warehouse operations. This small yet essential device features a streamlined structure that consists of several key components:

- Wheeled trolley

- Handle

- Hydraulic pump

- Linkages

- Load wheels

- Forks

Together, these parts work in harmony to facilitate the movement of heavy loads with ease and efficiency.

What Is the Difference Between a Forklift and a Pallet Jack?

A pallet jack is the most basic type of forklift.

But beyond that, how do you compare forklifts vs. pallet jacks?

Here are a few ways they are similar and different:

Forklifts Have a Counterweight

Most forklift designs rely on the counterbalance principle, meaning they use a heavy counterweight at the rear to balance the load on the forks.

However, pallet jacks do not work this way. Instead, wheels positioned at both ends of the machine support their weight.

Operators Sit or Stand Inside Forklifts

Except for hand-controlled stackers, most forklifts feature operator compartments where the operator either sits down or stands up.

However, with pallet jacks, operators typically control the jack while standing behind them on the ground.

That said, some models – like ride-on pallet jacks – allow operators to stand on the truck while they operate.

All Forklifts Are Powered – But Not All Pallet Jacks Are

Typically, Forklifts have an internal combustion engine or battery-powered electric motors to power their components.

Hand pallet jacks, conversely, require manual operation. However, motorized pallet jacks exist.

Generally, motorized pallet jacks operate using a battery and electric motor.

Lifting Elevated Loads

Forklifts are designed with high-lift vertical masts, offering lift heights ranging from 128 inches at the low end to 330 inches or more at the high end. This design enables them to lift loads for stacking or loading into pallet racking.

In contrast, pallet jacks are not for stacking. Instead, their components allow them to lift loads high enough off the ground (usually 6 to 7 inches) so operators can move them across the floor.

Frequently Asked Questions About Pallet Jacks

I am sure you have many questions about these handy pieces of equipment. Let’s dive into some of the most frequently asked questions about pallet jacks and hopefully provide answers to some of your inquiries.

Who Invented the Pallet Jack?

In 1939, George G. Raymond of the Raymond Corporation revolutionized the logistics industry with his groundbreaking invention, the pallet jack.

He received patents for both the pallet jack and the standard pallet design on November 7th, 1939.

Patent US2178647A introduced the “lift truck,” now commonly known as the pallet jack, while Patent US2178646A showcased the innovative two-faced wooden pallet design still widely used today.

What Are the Most Common Pallet Jack Dimensions?

What Is the Standard Width of a Pallet Jack?

Measured between each fork’s outer edge, the standard width of a pallet jack typically ranges from 20 to 27 inches.

However, it’s essential to note that variations in width can occur based on specific models and manufacturers.

How Wide Are Pallet Jack Forks?

The width of pallet jack forks, also known as blades or tines, commonly ranges from 6 to 7 inches, with most landing around 6.25 inches wide.

It is crucial to ensure that the width of the forks matches the dimensions of the pallets you’ll be handling to ensure safe and efficient operation.

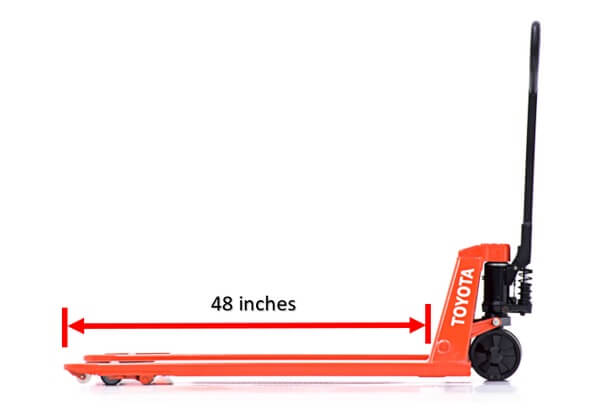

How Long Are Pallet Jack Forks?

The most common fork length for pallet jacks is typically 48 inches. However, variations exist based on the model and manufacturer. For instance, manual pallet jacks may have forks 36 or 42 inches long, while ride-on electric pallet jacks commonly feature fork lengths of 60 or 96 inches.

It’s essential to check the specifications of the specific pallet jack model to determine the exact fork length.

What Is the Smallest Pallet Jack?

Mighty Lift manufactures a hand pallet truck with a 16-inch width and 36-inch forks.

How High Does a Pallet Jack Lift?

As previously mentioned, pallet jacks are distinct from forklifts as they only transport loads rather than lifting them to significant heights.

Their lift heights are usually enough to raise the pallet slightly off the ground and nothing more.

Most manual pallet jack models have a maximum lift height of around 7 to 8 inches. However, there are exceptions, such as high-lift manual pallet jacks, which can elevate loads to heights up to 31.5 inches.

These variations cater to different needs and applications within warehouse and logistics settings.

How Much Can a Pallet Jack Lift?

Manual pallet jack lifting capacity maxes out around 5,500 lbs., though some models have a 10,000 lb. capacity.

Electric pallet jacks typically start at 4,500 lbs. capacity but can go up to 8,000 lbs.

What Is the Purpose of a Pallet Jack?

Are you curious about the functions of pallet jacks? Let’s explore their primary uses and benefits:

Reducing Manual Labor

The design of pallet jacks helps to reduce worker strain and fatigue.

Without them, manually transporting loads all day would lead to severe exhaustion for workers.

By utilizing pallet jacks, workers can significantly reduce the physical labor involved in transporting loads, thereby improving productivity.

Traveling Short Distances

While pallet jacks help reduce strain, they don’t eliminate it because operators must still provide the effort for locomotion.

In other words, manual pallet jack operators still put in the physical effort to maneuver the jack and the load.

Due to this fact, manual pallet jacks are best for short-distance travel, usually within warehouses or stockrooms.

That said, other types of pallet jacks can be used for long-distance travel.

For example, electric pallet jacks, specifically ride-on models, are a better option for moving loads over longer distances.

Operating in Tight Spaces

A pallet jack is the optimal choice when maneuvering a pallet in a tight space because it has a smaller footprint and turn radius than a regular forklift.

With a pallet jack, there is less concern about colliding with materials or infrastructure while navigating constrained spaces.

Specific Uses of Pallet Jacks

Lifting and moving loads over short distances

For example, moving pallets from a loading dock to pallet racks for storage and vice-versa.

Moving pallets within a semi-trailer

Often, semi-truck drivers use pallet jacks to rearrange freight within their trailer at stops. Then, they use the pallet jack to move the pallets from the trailer to the receiving dock.

Handling basic inventory duties

For instance, restocking grocery shelves by moving pallets from the storage area to the grocery shelves

Types of Pallet Jacks

While we have defined pallet jacks as straightforward forklifts, this category of material handling equipment encompasses numerous variations.

Let’s take a look at some of the most common types.

Manual Pallet Jacks

Also called “double fork pallet jacks” or “hand pallet trucks,” manual pallet jacks are the most basic type of pallet jack.

These are hand-operated vehicles with a handle and lever to control the lifting/lowering of the forks and the horizontal travel.

Some characteristics of manual pallet jacks include:

- Lifting capacities range from 1,000 lbs. to 5,500 lbs., with select models capable of handling loads up to 10,000 lbs.

- Most models don’t lift more than 7.75 inches.

- They are easy to maintain due to their simple parts and minimal components.

Electric Pallet Jacks

Are you wondering: What is an electric pallet jack?

Simply put, they’re manual pallet jacks with an added electric motor.

These trucks are also sometimes called “walkie pallet jacks.”

Why?

Because although they’re powered, the operator still must walk along with the truck.

Electric pallet jack features include:

- An electric motor which controls the hydraulic pump and forward and reverse travel

-

A twist-style throttle on the handle (just like a motorcycle) to control forward and reverse travel

-

A battery pack – either lead-acid or lithium-ion – that provides the power

-

Lifting capacities range from 4,500 lbs. up to 6,000 lbs.

-

Lift heights of around 9 inches.

Electric pallets are more expensive and require more operator training than manual pallet jacks.

But they have the advantage of improved productivity and less worker strain.

Stand-On Pallet Jacks

If you’ve heard these referred to by other names, you might be wondering: What are riding pallet jacks called

Other names include:

- Stand-up pallet jacks

- Rider pallet jacks

- Ride-on pallet jacks

These jacks are like walkie pallet jacks but feature a small platform on which the operator can stand during operation.

And because operators can stand on them, they’re better suited for long-distance pallet transport.

Center-Rider Pallet Jacks

These are a particular type of stand-on pallet jack.

In these models, instead of the operator standing on a small platform at the rear, they stand within a semi-enclosed operator compartment.

Additionally, instead of a tiller arm handle to control the truck, some center-rider models have a steering wheel for this purpose.

Off-Road Pallet Trucks

Other names for these trucks include:

- Outdoor pallet jacks

- All-terrain pallet trucks

The main features of these pallet jacks that make them different from others on this list are:

Tires

These trucks feature oversized, air-filled wheels instead of solid polyurethane wheels to handle rough terrain.

Frame

They feature a sturdier frame to endure bumps and shocks while maintaining load balance.

Forks

Other pallet jacks use linkages underneath the forks, which connect to the load wheels. But off-road pallet truck forks are mounted on a carriage directly connected to the hydraulic pump, making their lifting mechanism more like traditional forklifts.

Additionally, off-road pallet jacks can be powered manually by a battery and electric motor or by fuel and a gas engine.

Adjustable Pallet Jacks

A unique aspect of these machines is that operators can widen or narrow the forks using a hand-crank mechanism, making them useful in applications that handle different-sized pallets.

Because of this function, these jacks have the advantage of versatility.

After all, the operator doesn’t need multiple fixed-sized pallet jacks to handle various pallets.

Single Fork Pallet Jacks

As the name suggests, instead of 2 forks, these pallet jacks have a single fork that can move loads less than 14 inches wide, allowing them to handle much narrower loads than regular pallet jacks.

For example, they’re often used to transport safes, ATMs, and vending machines.

Collapsible Pallet Jacks

Collapsible pallet jacks, also known as “folding pallet jacks,” are a less common design.

These jacks are basically a regular double-fork manual pallet jack.

The difference is that the forks can fold up against the handle section.

This allows the pallet jack to be easily carried, lifted, or wheeled to specific locations to transport materials.

Their design simplifies transportation and saves space, especially when needed inside a truck or van.

Sideways Pallet Jacks

A sideways pallet jack is a variant of the standard manual pallet jack.

But whereas regular manual pallet jacks only move forward and backward, these trucks feature swiveling load wheels that allow the operator to move the jack laterally.

This feature is useful when handling wide loads since the operator can travel in the direction of the narrowest part of the load.

Roll-Moving Pallet Jacks

Wondering what kind of pallet jack to use for handling paper rolls?

The answer is a roll-moving pallet jack.

Instead of flat forks, roll-moving pallet trucks have angled forks designed to cradle the load so it doesn’t slip off.

Besides being used for paper rolls, these jacks are also used to handle other materials like:

-

Metal rolls

-

Plastics

-

Carpets

-

Cords

-

Fabric

How to Use a Pallet Jack

If you’ve never used a pallet jack before, you probably have questions about how to do so.

But before we cover that, let’s explain how a pallet jack works.

That way, the instructions for operating them will make a lot more sense.

How Does a Pallet Jack Work?

We said in the first section that a basic pallet jack consists of a few components, including:

-

Handle

-

Hydraulic pump

-

Wheeled trolley

-

Linkages

-

Load wheels

-

Forks

But how do all these parts work together in a pallet jack?

It’s actually pretty simple.

The handle is attached to the hydraulic pump, just above the main steering wheels.

And inside the handle is a lever.

When the lever shifts to the “lift” position, the operator pumps the handle up and down, which causes a piston in the hydraulic pump to rise.

This piston causes the linkages – which are beneath the forks and attached to the load wheels – to articulate.

As a result, this articulation causes the wheels and forks to rise.

When the operator is ready to lower the load, they place the handle lever in the “lower” position.

Consequently, the hydraulic pump releases pressure, reversing the process and causing the forks to lower to the ground.

How to Use a Manual Pallet Jack

Now that you understand the functions of a pallet jack, understanding their operation should be a breeze.

Here’s a simple summary:

- Ensure the lever on your pallet jack’s handle is in the middle (neutral) position.

- Use the handle to steer and push the pallet jack into position in front of a pallet.

- Squeeze the lever upward (towards your head) to lower the forks to the ground.

- Push the pallet jack forks as far through the pallet face as they’ll go.

- Ensure that the load wheels are not over a cross-piece underneath the pallet. Otherwise, raising the jack will break the pallet.

- Move the lever inside the handle into the lowest position (towards the floor) until it locks into place.

- Pump the handle up and down to raise the forks.

- Once the pallet is clear off the floor, return the lever to the middle (neutral) position.

- Move the pallet jack to your desired location.

- When ready to deposit the pallet, make sure the jack stops, then repeat step #3 above to lower the pallet.

Here’s a video showing how this whole process works:

How to Operate an Electric Pallet Jack

Before delving into how to operate an electric pallet jack, it’s crucial to address a fundamental question.

And that question is:

Do You Need a License to Operate an Electric Pallet Jack?

Yes, you do.

OSHA requires that anyone who operates a powered industrial truck receive training and certification to do so.

So, what is a powered pallet jack considered to be?

Is a powered pallet jack a powered industrial truck?

Yes, it is.

Specifically, it’s considered a Class III: Electric Motor Hand or Hand/Rider Truck, indicating that training for motorized pallet jacks must adhere to OSHA standard 1910.178(l).

Luckily, we have covered this topic in detail in our How to Get Your Forklift License: The Ultimate Guide.

Be sure to check out our article to learn everything you need to know about forklift training.

You can also receive online or in person training here…

Conger’s OSHA-compliant Forklift Operator Safety Training Course

12 Electric Pallet Jack Operation Steps

Operating an electric pallet jack is similar to using a manual pallet jack.

The two significant differences are that there’s no need to:

- Manually pump the handle to raise or lower the load

- Manually push or pull the jack to travel

Instead, you’ll utilize the lift and lower buttons and a twist-style throttle for horizontal movement.

Without further ado, here’s how to operate an electric pallet jack:

- Turn the pallet jack on. Some models have a simple on/off switch, while others have a key/ignition switch.

- Enter the access code. Some electric pallet jacks (like the Toyota model 8HBW23) have a keypad, which requires inputting a code to power up.

- Pull down the handle so it’s at a comfortable height.

- Use the twist-throttle on the handle head to move the jack forward and backward.

- Use the handle to steer the pallet jack into place in front of a pallet.

- Use the fork lower button to lower the forks to the ground.

- Drive the pallet jack into the pallet as far as it can go.

- Ensure that the load wheels are not over a cross-piece underneath the pallet. Otherwise, raising the pallet jack will break the pallet.

- Use the lift button to lift the forks and pallets until they’re clear off the ground.

- Use the twist-throttle to move the pallet to your desired location.

- Once ready to set the pallet down, use the lower button to lower the forks and load

- Use the throttle to remove the jack from the pallet.

Watch this video to see how to move a load with an electric pallet jack:

Frequently Asked Questions About Pallet Jack Operation

Do Pallet Jacks Have Brakes?

Manual pallet jacks lack brakes, making it crucial to use them properly to avoid accidents. Conversely, electric pallet jacks come equipped with a brake on the tiller handle head and are known as a “belly bumper” switch.

This button is designed to stop the truck and launch forward if the switch makes contact with the operator.

Do You Push or Pull a Pallet Jack?

Answer: Push.

Why?

- A person can push four times as much as they can pull

- Your legs have stronger muscles, so they can provide more support when pushing

- Pushing help avoid you pinning yourself against other objects in the event you need to stop quickly but can’t

- By not having to twist to look forward, pushing saves your back

- Pulling can strain your neck and limit your vision since your pulling arm causes your body to contort

- Pushing helps prevent your foot from making contact with the front wheels, which can cause you to trip

That all said, it’s acceptable to pull when pushing isn’t feasible, but try to limit pulling to situations when you are not moving the pallet jack and it does not have a load on it.

How to Raise a Pallet Jack

We’ve covered this above in the manual pallet jack operation section.

But just in case you’re still confused, here’s how to do it:

- Move the lift/lower lever into the lowest position

- Pump the handle to raise the forks

With electric pallet jacks, you use the lift button to raise the forks.

Buying a Pallet Jack: Everything You Need to Know

To assist you in determining which pallet jack to purchase, let’s discuss the most critical factors.

What Is Your Workspace Layout, Environment, and Load Size and Shape?

Here are some recommended pallet jacks according to different workspaces:

- Narrow aisles and Small spaces: An electric or manual pallet jack

- Wide-open spaces and far travel distances: A walkie or rider electric pallet jack

- Outdoor work or work on uneven terrain: An off-road pallet jack

- Lots of different-sized pallets: An adjustable pallet jack

How Much Weight Do You Need to Lift?

Recall that manual pallet jacks max out around 5,500 lbs.

But electric models can lift 6,000 to 8,000 lbs.

And be aware that constantly handling heavyweights, even with a manual pallet jack, can cause fatigue.

So, if that’s the case, consider an electric model to reduce fatigue and strain.

What Is Your Budget?

Manual pallet jacks are significantly cheaper to buy and operate than electric pallet jacks.

So, if you only need a jack occasionally, consider opting for a manual jack.

One way to lower the cost is by renting – especially if you only need the jack for short periods.

How Much Is a Pallet Jack?

The cost of a pallet jack depends on its type, size, model, and manufacturer.

That said, here’s a general range of prices:

-

Manual pallet jacks cost anywhere from $300 to $800

-

Walkie electric pallet jacks cost from $5,000 to $6,000

It’s worth noting that walkie-pallet jack prices typically include the battery. However, when purchasing a large pallet jack, such as a ride-on pallet jack.

However, when buying a large pallet jack, like a ride-on pallet jack, you may need to purchase the battery separately.

This additional expense can add another $4,000 to the total price.

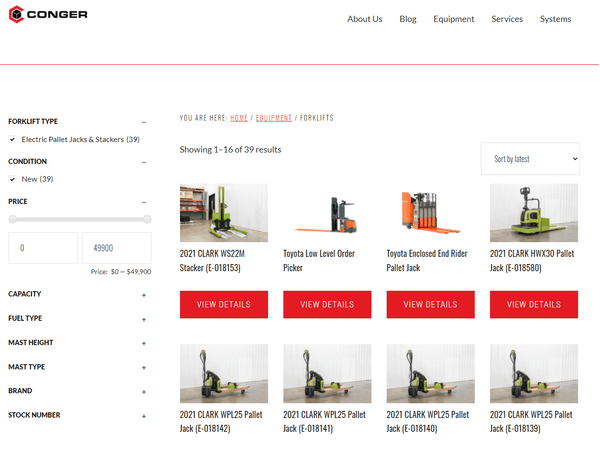

Where to Buy a Pallet Jack?

You can find manual pallet jacks in big-box stores like Home Depot and Harbor Freight.

Additionally, you can check with your local material handling dealer to see their selection of hand pallet trucks.

Typically, people purchase electric pallet jacks from equipment dealerships.

And equipment dealerships often carry only particular manufacturers.

For instance, Toyota, CLARK, Raymond, and Crown are popular pallet jack manufacturers.

So, you’ll probably need to do a little googling to find the dealer closest to you who carries these lines.

Conclusion

That’s it: Everything you need to know about pallet jacks.