Product Description

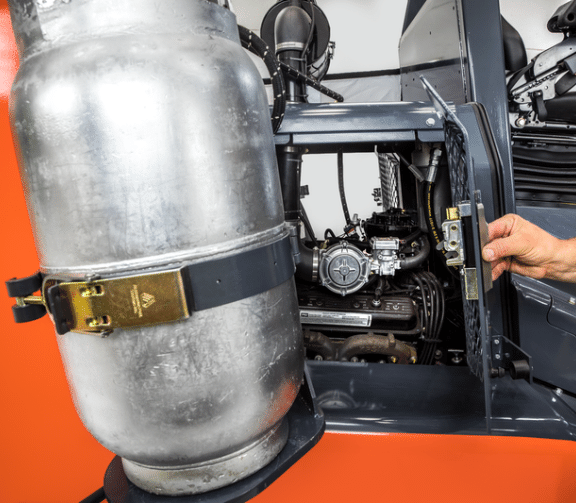

Toyota’s impressive THD power is now indoors. Think automotive and forging. Huge paper rolls. Steel and raw materials. All demand the reliable power that Toyota provides. With a V8 engine and rugged design, the Toyota High-Capacity Large IC Cushion forklift can handle anything you throw at it.

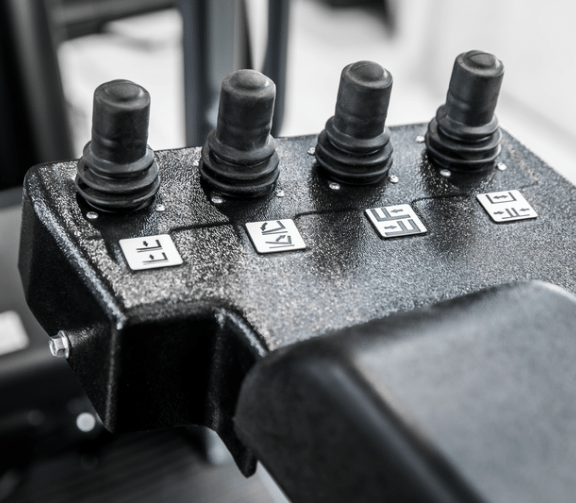

Toyota demands the best for its customers. The U.S.-built High Capacity Large IC Cushion is engineered from the ground up as a complete product. One with better components and well-thought-out integrated systems that work together to deliver intuitive, dependable performance day after day.

Model Numbers: THDC2500-24 | THDC3000-24 | THDC3500-24 | THDC2500-30 | THDC3000-30 | THDC4000-30 | THDC4500-30 | THDC5000-30 | THDC3000-36 | THDC4000-36 | THDC4500-36 | THDC5000-36 | THDC5500-36