Product Description

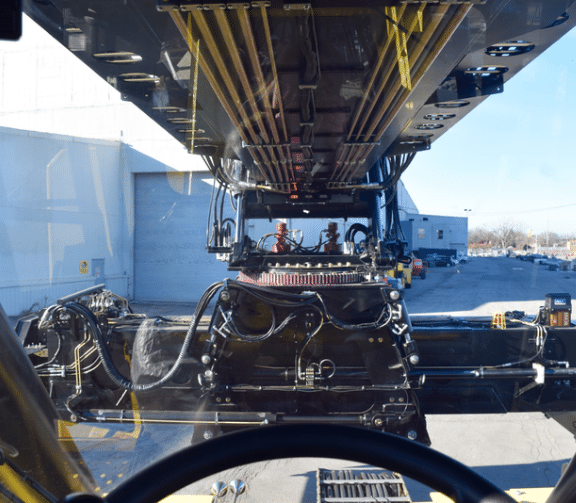

The Toyota Reach Stacker Container Handler can handle a diverse range of heavy-lift applications, from loading and unloading trailers to transporting wind turbine components. It also offers front stabilizers for second and third rail operations. As well as twistlock, pin-style and trailer attachments.

Stack up to 5 containers high and reach 3 rows deep with the Toyota reach stacker container handler. It’s standard damage prevention system utilize ultrasonic sensors to decrease container damage and increase attachment longevity. Plus, shacklepoints on the container handler mean it can be used as a crane for additional applications.

Model Numbers: THD9900-R60 | THD9900-R68 | THD9900-R73 | THD9900-R77 | THD9900-R85 | THD9900-R90