For decision-makers in maintenance and operations, understanding common forklift parts is more than just technical know-how – it’s key to ensuring efficient operations, minimal downtime, and operator safety.

Whether you’re managing a fleet of electric forklifts or propane-powered forklifts, knowing the major parts of a forklift (and the replacement parts they often need) will help you make informed purchasing and maintenance decisions.

This guide breaks down the parts of a forklift – from big components like the mast and tires to smaller replacement parts – with practical insights for keeping your lift trucks in top shape.

Let’s dive in!

Major Forklift Components

Most forklifts (especially the common counterbalance forklift) share a similar design and set of major components. Below are the major parts of a forklift and their functions:

Forklift Mast (Lift Assembly)

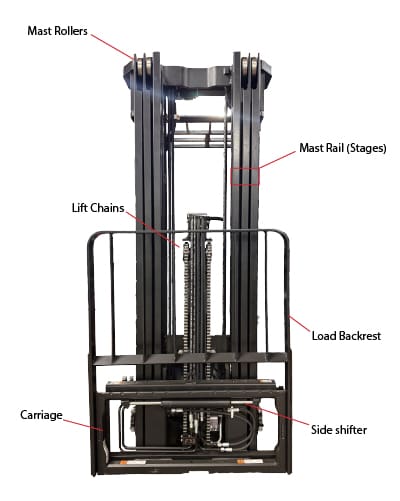

This is the vertical structure at the front of the forklift that raises and lowers loads. The mast consists of interlocking sliding rails (often two sliding rails in a standard two-stage mast) that provide vertical lift.

Hydraulic lift cylinders (hydraulic lift cylinders) and chains inside the mast allow the carriage and forks to move up and down. The mast also includes tilt cylinders that control forward and backward tilt for load stability – allowing the mast to tilt forward (for picking or depositing loads) or backward (to secure heavy loads during travel).

Attached to the mast is the carriage, a platform that holds the forks and other attachments. A load backrest is usually bolted to the carriage to prevent the load from shifting or falling toward the operator. In essence, the mast and its components handle the vertical movement of the forks and ensure loads can be lifted, lowered, and tilted safely.

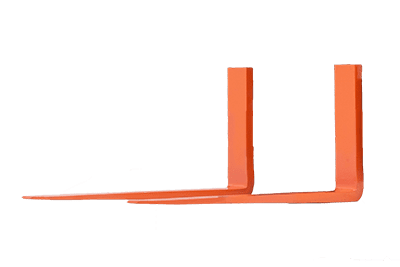

Forks (Tines)

Forks are the pair of steel prongs that actually lift and carry loads. They mount to the carriage and slide under pallets or materials to support them from underneath. Often called fork tines or blades, the forks on a forklift are built to handle very heavy loads. They come in various lengths (e.g., 42″, 48″, 72″) to suit different applications, but all forks serve the same purpose – to carry loads safely.

Truck Frame & Counterweight

The frame is the rugged steel support structure that forms the base of the entire forklift. It includes the chassis and typically houses major parts like the engine (or battery) and the mast assembly.

Integral to the frame at the rear is the counterweight – a large, heavy mass (often cast iron) that counterbalances heavy loads on the forks. In a counterbalance forklift, the counterweight offsets the weight of the load lifted at the front, preventing the forklift from tipping forward. The heavier the load a forklift can lift (its lifting capacity), the heavier the counterweight needs to be.

For example, electric forklifts use their massive battery as part of the counterweight, whereas gas and diesel forklifts or propane-powered forklifts have a dedicated iron counterweight built into the frame. The combination of a strong truck frame and adequate counterweight ensures the forklift remains stable when lifting very heavy loads.

Power Source (Engine or Battery)

Every forklift has a power supply that drives its operation. Internal combustion forklifts (running on gasoline, diesel, or propane) have an engine under the hood, typically mounted beneath or behind the operator’s seat.

These forklifts have a fuel tank – for example, a propane forklift uses a pressurized propane cylinder typically mounted on the rear of the truck, while gas/diesel models have built-in tanks in the frame. Key engine-related components include the ignition system (spark plugs, distributor cap, rotor), filters (air filter, oil filter, fuel filter), a cooling system (radiator and fan belt), and the drivetrain (transmission to drive the wheels).

On the other hand, electric forklifts use an industrial battery as the power source, so they don’t have an engine or fuel system. Instead, the battery and electric motors provide energy to drive the hydraulic pump and electric drive motors. In both cases, the power source is what propels the lift truck and runs its hydraulic system. Keeping the engine or battery in good condition – along with related parts – is vital for reliable performance.

Wheels and Tires

Forklifts typically have two sets of wheels: drive wheels at the front and steer wheels at the rear. The front drive wheels are powered by the engine or electric motor to move the forklift forward or reverse, and they support the bulk of the load (they are usually fixed in position, not used for steering). The smaller rear wheels are steer tires, which pivot to turn the forklift.

Forklift tires come in two main types: cushion tires and pneumatic tires.

Cushion tires are made of solid rubber and are best for indoor use on flat surfaces (like warehouse concrete floors) – they provide a smooth ride on smooth floors but are not suited for uneven terrain.

Pneumatic tires are air-filled (or foam-filled) tires similar to truck tires; these air pneumatic tires have deep tread and are designed for outdoor or rough terrain, providing better grip and shock absorption on uneven surfaces. Some forklifts even use solid rubber pneumatic-style tires (resilient tires) to avoid flats while still handling outdoor conditions.

It’s important to choose the right tire type for your environment and to replace worn tires promptly – tires affect stability, braking, and the forklift’s ability to carry heavy loads safely.

Operator Cabin & Controls

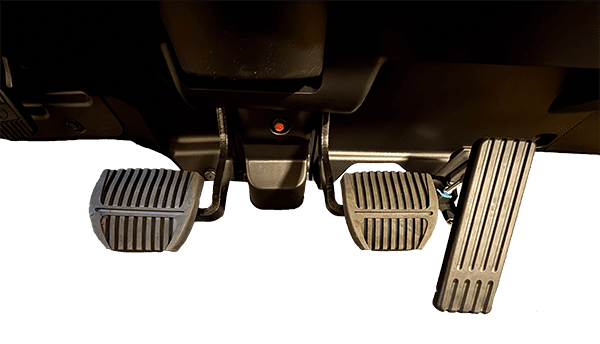

The operator compartment (cab) is where the forklift operator sits to drive and control the forklift. This area includes the operator’s seat, usually equipped with seat belts for safety, and the steering wheel used to maneuver the truck.

You’ll also find various pedals on the floor: an accelerator (gas pedal) to control speed, a brake pedal for stopping, and often an inching pedal. The inching pedal allows fine control by disengaging the transmission—letting the operator rev the engine (for hydraulic power) without moving or only inching the forklift forward/backward. Using this pedal, a skilled maintenance technician or operator can precisely position the forklift when lifting or placing loads.

Forklifts also have levers for mast controls: typically at least two hydraulic control levers – the lift lever (to raise/lower the forks) and the tilt lever (to tilt the mast forward or backward). These tilt cylinder controls let the operator adjust the mast angle for improved load handling (a slight backward tilt keeps the load against the backrest for stability, while forward tilt helps in depositing loads). Additional controls or switches may operate attachments or other features (e.g., side shifters, horn, lights). The operator cab also contains an instrument panel with gauges and a capacity plate (data plate).

- Lift Lever – Raises and lowers the forks along the mast, allowing operators to pick up loads from the ground or place them at various heights during stacking and storage.

- Tilt Lever – Tilts the mast forward or backward to stabilize the load. Tilting back helps secure heavy loads during travel, while tilting forward allows for precise placement.

- Side Shift Lever – Moves the forks left or right without repositioning the forklift, enabling accurate load alignment and reducing the need for additional maneuvering.

- Auxiliary Lever – Controls optional attachments such as fork positioners, clamps, or push-pull devices, expanding the forklift’s functionality beyond standard pallet handling.

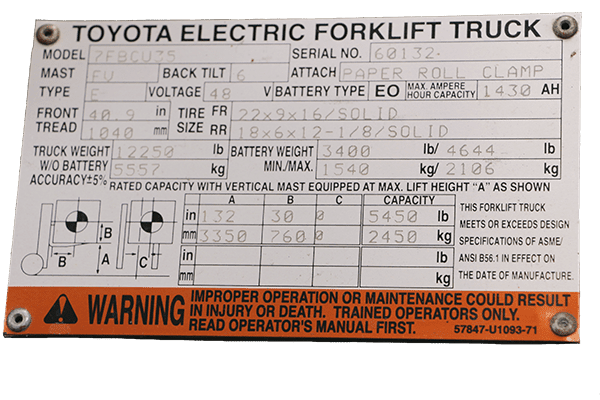

The operator cab also contains an instrument panel with gauges and a capacity plate (data plate). The capacity plate is a safety information tag that lists the forklift’s lifting capacity, model, weight, and other important specs. Operators must read the capacity plate to know the limits of the truck (e.g. how heavy a load it can safely lift at a given height and load center). All these controls and displays in the cab help the operator run the forklift efficiently and safely.

Overhead Guard & Safety Features

Above the operator’s seat is the overhead guard, a metal roof-like framework that protects the operator from falling objects. The overhead guard is a critical safety device – it’s basically a cage or canopy that will stop small debris or boxes from hitting the driver. (However, it’s not designed to bear the weight of an entire heavy load dropping from height, so safe handling is still paramount.)

Many forklifts also have an overhead guard cover or screen; for example, a heavy-duty plastic or steel grate can be added on top to shield the operator from rain or tiny debris without impeding visibility.

In front of the operator, attached to the mast, is the load backrest, which was mentioned earlier. It’s a grated frame that keeps the load from sliding backward off the forks, further protecting the driver.

Other safety devices and accessories on a forklift include the horn (usually built into the steering wheel) to alert pedestrians, lights (headlights, tail/brake lights, warning strobe lights or blue spotlights for visibility), and mirrors for rear visibility. Modern forklifts also feature things like backup alarms that sound when reversing, and some have seat sensors that prevent operation if the operator isn’t properly seated.

Parking brakes are provided to secure the lift truck when stationary. All these components – from the overhead guard to the horn and mirrors – work together to enhance operator safety and prevent accidents. Maintaining these safety features (for instance, ensuring the horn works, lights are intact, and the overhead guard is not damaged) is just as important as maintaining the engine or hydraulics.

Common Forklift Replacement Parts

In daily operation, various forklift parts experience wear and tear. Proactively replacing these replacement parts at recommended intervals keeps your forklift running smoothly and prevents minor issues from causing major downtime. Below is a list of common forklift parts that companies often keep on hand (especially for internal combustion models like propane, gas, or diesel forklifts) and a brief description of each part’s purpose:

Oil Filter

Keeps engine oil clean by trapping dirt and metal particles, protecting internal engine components from premature wear. (Regular oil and filter changes are crucial for internal combustion forklifts’ engines.)

Forklift Chain

The lift chain on the mast transfers lifting force from the hydraulic cylinders to the carriage and forks. It bears the load during lifting, allowing the mast to raise and lower smoothly through its stages.

Air Filter

Removes dust and debris from the engine’s intake air. A clean air filter ensures proper air flow for combustion and protects the engine from ingesting harmful particles – especially important in dusty warehouse or outdoor environments.

Spark Plugs

Ignite the fuel–air mixture in internal combustion forklift engines (found in propane-powered forklifts as well as gasoline or diesel models that use spark ignition). Worn spark plugs can cause misfires or hard starting, so they should be replaced as part of routine tune-ups on IC forklifts.

Pedal Pad

The rubber (or heavy-duty plastic) pad on the surface of forklift pedals. It provides traction and comfort for operators’ feet on the controls (such as the brake and inching pedals), and can wear down over time. Replacing worn pedal pads ensures the operator’s foot doesn’t slip off the brake or other pedals during operation.

Horn

An audible alert device that enhances safety by allowing the operator to warn pedestrians and other workers of the forklift’s presence. Forklift horns are used when approaching intersections, blind corners, or anywhere people might be nearby. A functioning horn is required safety equipment – if it fails, it should be fixed or replaced immediately.

Distributor Cap

Part of the ignition system in older or traditional internal combustion engines. The distributor cap routes high-voltage electricity from the ignition coil to the correct spark plug in sequence. Cracks or carbon tracking in the cap can cause misfires, so it’s a common replacement item during ignition system maintenance (on forklifts that aren’t distributor-less).

Rotor

Another ignition component found inside the distributor cap. The rotor spins as the engine runs, briefly making contact to send current to each spark plug wire terminal at the correct time. Like the distributor cap, the rotor can wear or burn over time and is typically replaced along with the cap to keep the ignition system in top shape.

Fan Belt

Also known as the drive belt, this loops around pulleys to drive engine accessories like the alternator, water pump, and cooling fan. In a forklift engine, the fan belt is essential for the cooling system and charging system. If it frays or snaps, the engine can overheat or the battery won’t charge, so regular inspection and replacement of belts is necessary.

Fuel Filter

Strains impurities (dirt, rust, sediment) out of the fuel before it reaches the engine’s fuel system. A clean fuel filter is critical for gas and diesel forklifts and propane units alike – it ensures clean fuel delivery, prevents clogs in fuel injectors or carburetors, and helps the engine run smoothly. Replacing the fuel filter at recommended intervals will help maintain engine performance and fuel efficiency.

Each of these parts plays a role in the forklift’s reliability and performance. Having the right replacement parts on hand (or a reliable supplier to get them quickly) can save you significant downtime.

For example, something as simple as a clogged air filter or a worn fan belt can take a forklift out of service if not addressed. Maintenance teams should include these common items in routine inspections – checking oil and filters, examining chains for wear, inspecting tires, testing the horn and lights, etc. – to catch issues early.

It’s also wise to consult the forklift’s manual and the manufacturer’s guidelines for how often to replace each component. (Many parts, like filters and spark plugs, have recommended service intervals.)

Keeping Your Forklift Running

Forklifts are powerful, highly engineered machines made up of many interdependent components—and when even one part fails, it can bring operations to a halt. By understanding the major parts of a forklift and the replacement components that wear out most often, you can take a proactive approach to maintenance that reduces downtime, improves safety, and extends the life of your equipment.

Routine inspections, timely replacement of wear items, and adherence to manufacturer-recommended service intervals help prevent small issues from becoming costly repairs. Investing in high-quality replacement parts and working with qualified technicians ensures proper fit, reliable performance, and long-term value—whether you’re maintaining a single lift truck or managing a large fleet.

Ultimately, knowing your forklift parts isn’t just about equipment—it’s about protecting operators, maintaining productivity, and controlling operating costs. Use this guide as a reference, and you’ll be better equipped to keep your forklifts running efficiently, safely, and reliably for years to come.