Product Description

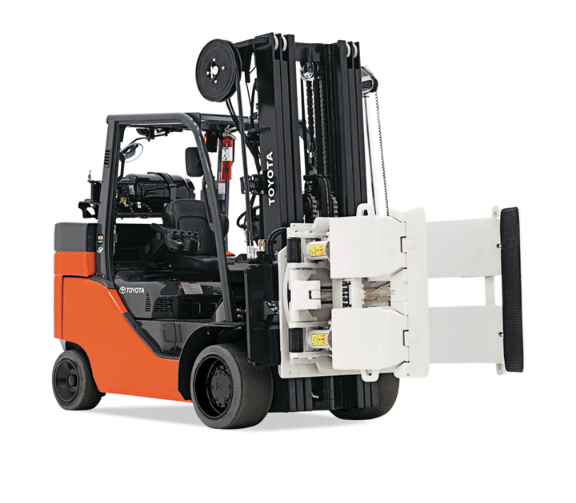

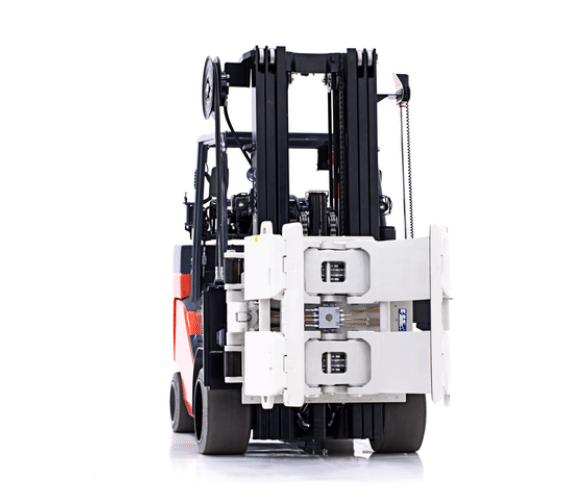

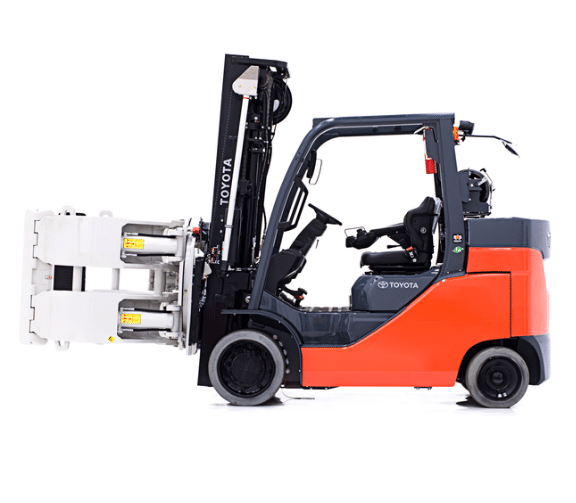

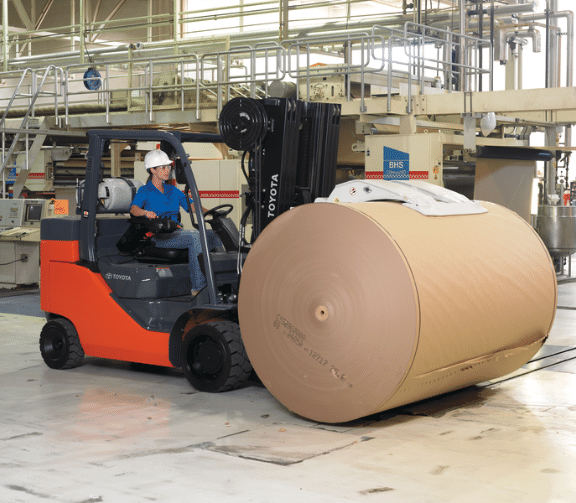

The product: Heavy, awkward, easily damaged. The environment: Dusty, dirty, did we mention dusty? Paper handling presents exacting demands. The Toyota Paper Roll Special forklift meets them, safely and efficiently. Equipped to stack and maneuver heavy paper rolls, it’s the perfect solution for paper mills, printing plants, newspaper production, and similar applications.

Not to mention, the special-built counterweight with a cast iron enclosure specifically shaped to reduce paper roll contact. This design provides better weight distribution, lower center of gravity and improved truck stability. With the Toyota Paper Roll Special forklift, your paperwork gets done.

Model Numbers: 8FGC55U-PRS