Renting a forklift can be a smart, cost-effective solution for businesses that need equipment on a temporary basis. However, choosing the right forklift rental involves much more than selecting a model and signing a contract.

To ensure safety, efficiency, and value, it’s essential to carefully assess your operational needs, understand equipment capabilities, and evaluate the terms of your rental agreement. From identifying the right forklift type and power source to selecting a trustworthy provider and avoiding common pitfalls.

In this guide we will walk you through every step of the rental process to help you make an informed, confident decision.

Let’s dive in!

Assessing Your Needs

Before you start looking at rental forklifts, take time to assess your specific needs. Factors such as your project requirements, the loads you’ll handle, and the work environment all help determine what kind of forklift you should rent.

Project Requirements

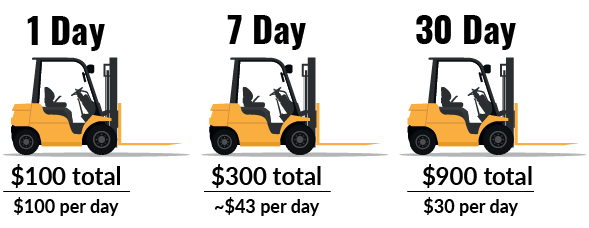

Begin with the basics of your project. How long will you need the forklift? Define the rental duration – whether it’s a single day, a few weeks, or several months.

Forklift rentals can be as brief as a day or extend to ongoing extended forklift rental arrangements for long projects. Keep in mind that rental providers typically offer better prices for longer term rentals.

Load Considerations

Next, evaluate what loads the forklift must handle. Every forklift has limits on how much weight it can lift and to what height. Determine the maximum weight you will need to lift and ensure you rent a forklift with sufficient capacity (plus a safety margin) so you’re not pushing the equipment to its limits.

Know the height requirements as well – for example, lifting pallets to a second-story mezzanine or stacking materials on high racks will require a forklift with an appropriate mast height.

Also account for load dimensions and stability. If your loads are unusually wide, long, or awkwardly shaped, you may need a forklift with special attachments or a higher capacity than the weight alone would indicate, to keep the load stable at height.

Operational Environment

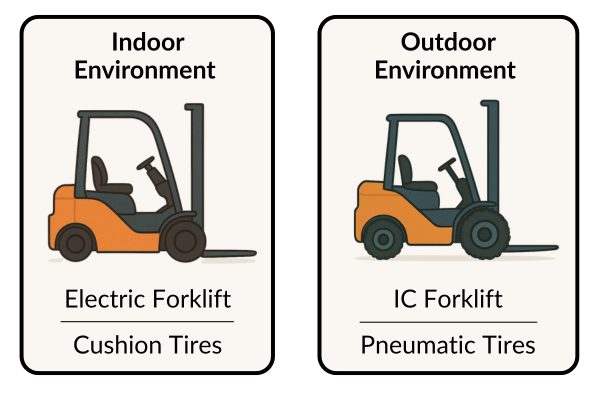

The operating environment will dictate the type of forklift and tires that are suitable. For example: a smooth concrete warehouse floor is ideal for electric forklifts with cushion tires, while a rough outdoor terrain (gravel, dirt yards, construction sites) calls for forklifts with pneumatic tires and robust suspension.

If the work is indoors, check your aisle widths and space constraints. In tight spaces or narrow warehouse aisles, you may need a specialized model – for instance, a stand-up reach truck or narrow aisle forklift rental – designed to maneuver in confined areas. Ensure the forklift’s turning radius and size can comfortably fit your facility’s layout.

Selecting the Right Forklift

Once you’ve outlined your needs, the next step is choosing a forklift that meets those requirements. Forklifts come in various types with different power sources and optional attachments. Selecting the right one will improve efficiency and safety on the job.

Forklift type is a crucial consideration. There are electric forklifts and internal combustion (IC) forklifts, as well as various designs like counterbalance forklifts, reach trucks, order pickers, pallet jacks, and more.

A standard counterbalance forklift (the typical front-loading forklift) is versatile for many tasks, but other models are purpose-built.

For example: reach trucks and order pickers excel at lifting and retrieving pallets in high warehouse racks, while walkie pallet jacks or walkie stackers are ideal for moving pallets over short distances on a warehouse floor.

Think about the specific tasks – if you need to unload trucks and move pallets in a yard, a standard counterbalance lift might be best; if you’re working in narrow aisles retrieving inventory, a reach truck or narrow aisle forklift is more appropriate.

Fuel Type Considerations

Decide on the power source that makes sense for your situation.

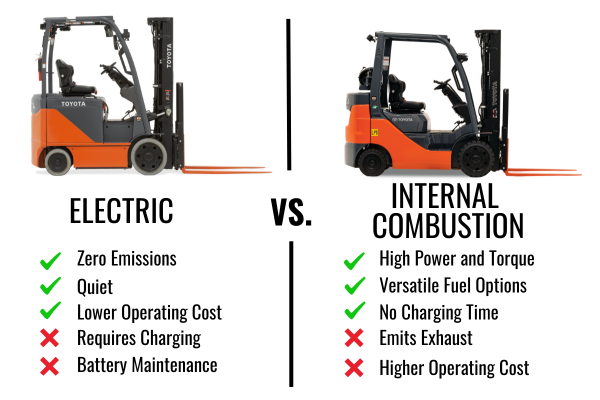

Electric forklifts are battery-powered and produce zero emissions, which makes them ideal for indoor use and food storage warehouses where air quality is important. They are also quieter and often cheaper to run per hour, though they require charging (or charged spare batteries) and generally are suited for flat, even surfaces.

Internal combustion forklifts – which include diesel, gasoline, and LPG (propane) models – are typically used outdoors or for heavy-duty applications. Diesel forklifts offer a lot of torque for tough jobs and are common on construction sites, while propane forklifts are versatile for indoor/outdoor use if the area is well-ventilated.

Keep in mind fuel availability and any facility restrictions: for instance, propane forklifts emit some exhaust and should only be used indoors in large, ventilated spaces. Also factor in things like noise and maintenance (e.g., electric forklifts have less engine maintenance but you must maintain battery water levels, whereas propane/diesel require engine upkeep and fuel management).

Choose a power type that aligns with your work environment and ensures compliance with any emissions or noise regulations at your site.

Attachments and Accessories

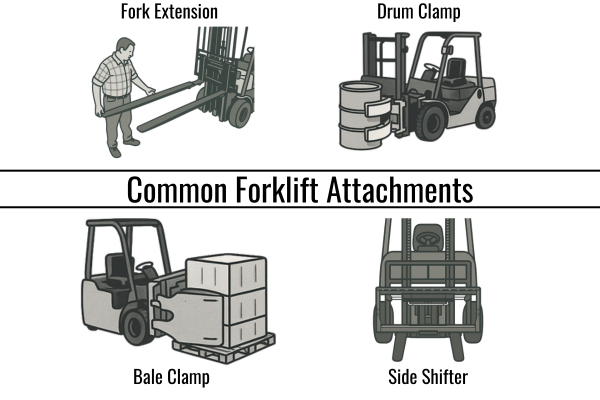

Forklifts can be equipped with a variety of attachments to handle special tasks, so consider if your job would benefit from any. Common forklift attachments include fork extensions, fork positioners, side shifters, multiple pallet handlers, load backrests, and clamps for things like bales, cartons, or drums.

These attachments can greatly enhance a forklift’s capability – for example, a side shifter allows the forks to move left or right without moving the whole truck, making lining up loads easier, and a drum clamp can safely grip and lift cylindrical loads.

When renting, inquire what attachments are available and ensure the forklift you choose is compatible with them (attachments can affect the forklift’s effective capacity). Only use attachments if needed for your materials, and make sure to request them in advance so the rental provider can supply and install them.

Evaluating Rental Providers

Not all rental companies are equal. Once you know the kind of forklift you need, you should also choose a reputable rental provider. Evaluate potential providers on several key factors to ensure you’ll receive reliable service and support during your rental period.

Reputation and Experience

Look into the reputation and experience of the rental company. How long have they been in business, and what do other customers say about them? A provider with many years of experience in forklift rentals and positive client testimonials is more likely to be trustworthy and provide quality equipment.

Check for online reviews or ask for references. You’ll want a company known for dependability, timely service, and fair dealing. An established dealer (for example, an authorized distributor of a major forklift brand) often indicates they meet certain quality and service standards. Reputation matters because it reflects how well the company maintains its equipment and treats its customers – crucial aspects when you might need quick support or repairs.

Equipment Availability

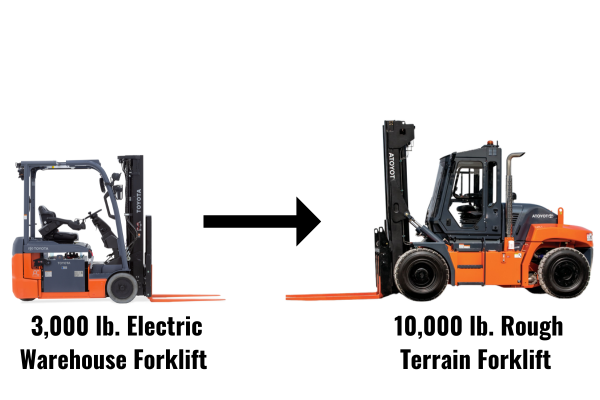

Ensure the rental company offers the equipment availability that matches your needs. A good rental provider should have a range of forklift models and capacities in their fleet. This means they can supply exactly the type of forklift you require – whether it’s a 3,000 lb electric warehouse forklift or a 10,000 lb rough-terrain forklift.

Verify that the specific model you need (and any attachments) are available for the dates you want. It’s also wise to ask about backup equipment: if the forklift you rent has an issue, does the company have others available to swap in so you don’t lose productivity? Availability also extends to fleet age and condition – a provider with newer or well-maintained forklifts is preferable, as the machines will be more reliable and less likely to break down.

Support Services

Consider what support services the rental firm provides during and even before the rental. Maintenance and repair services during the rental period are critical. You should expect that routine maintenance is covered (more on that in the next section), and if the forklift malfunctions, the company will send a technician to fix it or provide a replacement quickly.

Ask about their response time for service calls and whether they offer 24/7 emergency support if you are working off-hours. Another valuable support feature is the availability of operator training programs or certified operators. Some companies can provide on-site training for your staff or even rent a forklift and driver together – supplying a qualified operator with the equipment – if you don’t have certified operators available.

While not every rental will include an operator, knowing that the company prioritizes safety training indicates a higher level of expertise and customer care. Choose a provider that stands behind their equipment with strong support and is willing to help you operate it safely and efficiently.

Understanding Rental Agreements

Before signing on the dotted line, it’s important to thoroughly understand your forklift rental agreement. Rental contracts contain specific terms and conditions that you need to be aware of to avoid unexpected costs or problems. Key components to review include the rental period, pricing, delivery details, maintenance responsibilities, and insurance requirements.

Rental Duration and Rates

Make sure the contract clearly states the length of the rental and the cost. Forklift rentals are often priced by the day, week, or month. If you’re wondering how much does it cost to rent a forklift for a day, the answer will depend on the forklift’s size and capacity. Forklift rental rates typically increase for larger or more specialized machines. For example, a standard 5,000 lb warehouse forklift might rent for around $250 per day, whereas a high-capacity 15,000 lb forklift could cost around $600 or more per day. Ensure you know the rate for the agreed period and whether that includes a certain number of usage hours (many rentals allot e.g. 8 hours per day or 40 hours per week). Also ask about overtime charges if you exceed the hourly usage – rental agreements often have per-hour fees for usage above the included hours.

Delivery and Pickup Logistics

Clarify how the forklift will get to your site and be returned. Rental companies can usually deliver the equipment to your location and pick it up when you’re done, for an added fee. Confirm the delivery fee and schedule. For local rentals, delivery is often relatively affordable (e.g. on the order of $100 one-way), but longer distances or expedited delivery will cost more. Plan a drop-off point that a large truck can access, such as a loading dock or yard, and ensure someone will be on-site to receive the equipment. Similarly, coordinate the pickup to avoid incurring extra days of rent. Knowing the logistics and costs of transportation upfront will prevent surprises on your invoice.

Maintenance Responsibilities

Verify who is responsible for maintenance and repairs during the rental. Routine forklift maintenance – like oil changes, lubrication, or replacing wear-and-tear items – is typically included in the rental price, meaning the rental provider will handle or pay for those, as long as the need is due to normal use. However, the renter is usually responsible for daily upkeep like charging the battery or refilling propane, and any damage beyond normal wear.

- Read the contract’s maintenance section: it should state that the rental company covers maintenance excluding damage (for example, if you damage a tire or break a fork, you pay for it).

- Also note if they require you to report issues or if they schedule service visits for longer rentals.

Liability and Insurance

Pay attention to liability clauses and insurance requirements. The agreement will likely specify that you (the renter) are liable for any injuries or property damage that occur while the forklift is in your possession. Most rental companies require the renter to carry adequate insurance for the forklift and its operation. This may include general liability insurance (to cover accidents or damage caused by the forklift) and sometimes physical damage coverage for the forklift itself (similar to car rental insurance).

- Check with your insurance provider if your business policy covers rented equipment; if not, you may need to purchase a temporary insurance rider or the rental company’s damage waiver. Never assume coverage – confirm you have insurance for the forklift rental to avoid huge costs in case of an accident. Also, ensure any operators you assign are properly licensed (which ties into liability as well).

- Hidden Costs: Additional fees can sometimes catch renters off guard, so scrutinize the contract for any potential extra charges:

- Late return fees: If you keep the forklift longer than the agreed rental period without extension, you could incur late fees or extra daily charges. Always communicate with the provider if you need to extend the rental to avoid these penalties.

- Damage charges: As noted, you will be charged for any damage beyond ordinary wear and tear. Inspect the forklift upon delivery and document any pre-existing dents or issues so you’re not blamed for them later. Likewise, clean the equipment and ensure it’s in good condition before pickup to avoid cleaning fees or damage claims.

- Fuel or battery service surcharges: Many rentals require you to return the forklift with the same fuel level as delivered (much like a rental car). If you rent a propane or diesel forklift, you may need to refill the tank before return or pay a refueling fee. With electric forklifts, ensure the battery is charged. Some companies add a fuel surcharge or energy fee if they have to refuel or if fuel prices fluctuated during your rental. Check these details so you can either handle refueling yourself or budget for the fee.

Always read the fine print of the rental agreement. If anything is unclear, ask the rental provider to explain. A reputable company will be happy to walk you through the terms. Understanding all the costs and conditions up front will prevent disagreements and unexpected expenses later on.

Common Mistakes to Avoid

Even with the best planning, there are a few common pitfalls people encounter when renting a forklift. Being aware of these mistakes can save you from trouble and expense:

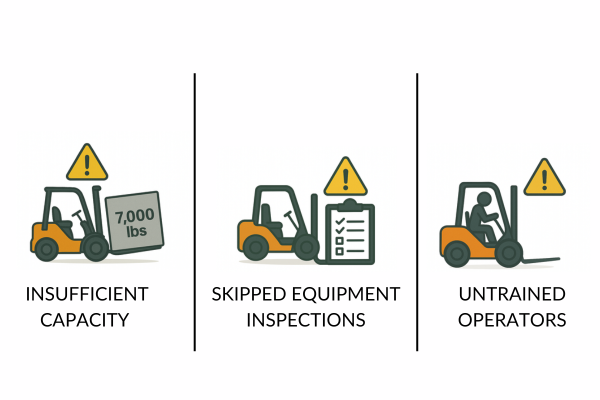

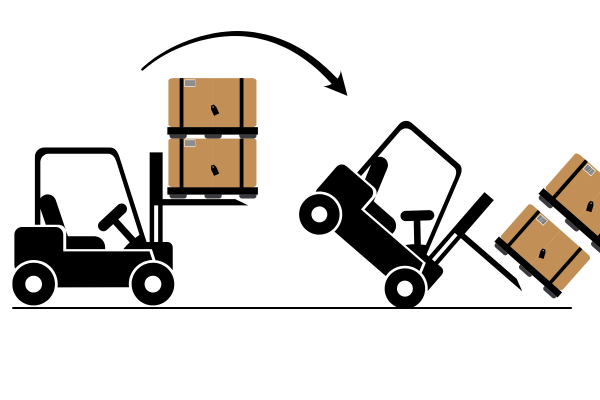

Underestimating Requirements

One frequent mistake is renting a forklift that doesn’t meet the necessary capacity or reach. For instance, choosing a forklift with insufficient lifting capacity for your heaviest load can lead to dangerous overload situations or an inability to complete the job. Similarly, not getting a tall enough mast for high lifts could stall your project. Always err on the side of a slightly higher capacity or extra lifting height if you are near the limits. Underestimating the equipment needs might save a little on rental rates initially, but it can cause costly delays, or worse, safety hazards if a forklift is pushed beyond its limits.

Overlooking Training Needs

Never assume that anyone can hop on the forklift and operate it safely. Not ensuring that operators are certified and trained is a critical mistake. OSHA regulations require that all forklift operators be properly trained and certified, and for good reason. It is estimated that 20%–25% of forklift accidents are at least partly caused by inadequate training.

If your team doesn’t include a licensed forklift driver, consider sending employees to a certification course or see if the rental company can provide operator training or a temporary operator. Never let an unqualified person operate the rented forklift, even for a short task – the risks are too high. Invest time in safety training and you will protect your staff and your business.

Neglecting Equipment Inspections

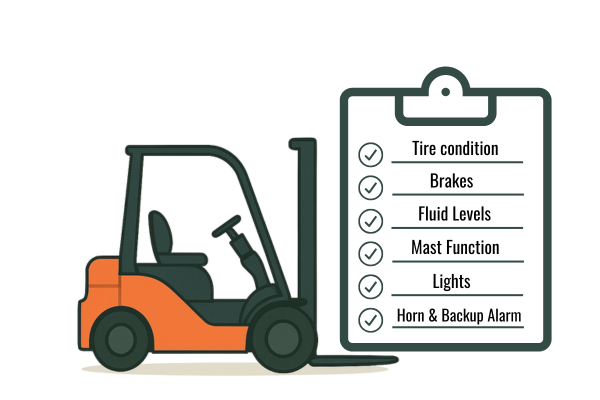

Another mistake is failing to inspect the forklift when it arrives and throughout the rental period. When the rental is delivered, do a thorough walk-around inspection with the delivery person. Check for any existing damage, test the controls, and make sure all lights and safety devices are working. Document (and ideally, photograph) any issues and inform the rental company immediately so you’re not held responsible later.

During use, perform daily pre-operation inspections of the forklift – this includes checking tire condition, fluid levels, brakes, mast and forks, and safety features like the horn and backup alarm. (These pre-shift inspections are actually required by OSHA for each day or shift of use.) If you neglect these checks, you might miss a developing mechanical problem that could lead to a breakdown or accident or blamed for damage that occurred before your rental.

Conclusion

Renting a forklift can offer tremendous benefits in efficiency and flexibility for your business, as long as you approach it thoughtfully. By assessing your needs upfront (project duration, load capacities, and environment), selecting the right forklift type and attachments, and choosing a reputable rental provider with the equipment and support you require, you set the stage for a successful rental experience.

Always review the rental agreement in detail so you understand the costs, terms, and your responsibilities, and avoid common mistakes like under-spec’ing the forklift, neglecting operator training, or skipping inspections. Most importantly, keep safety and compliance at the forefront by using trained operators, inspecting the forklift daily, and maintaining a safe worksite with proper procedures.

By considering all these factors before renting a forklift, you’ll ensure that the equipment truly solves your short-term needs without creating new problems. If you have any doubts or need guidance, don’t hesitate to consult with forklift rental experts to get advice tailored to your situation. With the right planning and expert support, you can leverage forklift rentals to boost your operations while keeping costs down and safety standards high. Good luck with your project, and safe lifting!