Forklifts are just like any other piece of heavy-duty machinery: They need a little TLC from time to time. And if you’re in charge of general forklift maintenance, this task falls on you.

If you feel overwhelmed, do not fret—you are in the right place.

This article will guide you through the maintenance protocols to keep your lifts in top shape, ensuring they remain efficient, productive, and safe. What’s more, we will share some tips on how to save money along the way.

Specifically, we’ll cover:

- The benefits of regularly maintaining your heavy-duty forklifts

- Your OSHA-mandated maintenance obligations

- What are the different maintenance intervals that are

- What factors influence how often you should service your equipment

- How to calculate your maintenance costs (including a free forklift maintenance calculator)

- Tips for saving money on maintenance

We will also simplify the process to ensure you do not overlook any steps. You will have access to nine free, downloadable maintenance checklists for each service interval (in Excel and PDF formats).

Let’s dive in!

Forklift Maintenance Benefits

Regularly performing maintenance tasks yields some crucial benefits for your forklift operation.

Let’s go through the biggest ones.

Longer Service Life

The more regularly a lift is serviced, the longer it will last and the more productive it will be. It will lead to a better economic life for the forklift and a better return on investment (ROI).

Better Productivity

Regular maintenance means more uptime because the more the lift truck can run, the more your operation can produce. Plus, you can minimize disruptions to the production schedule by proactively planning maintenance around it.

Money Savings

Through regular forklift maintenance, you will be more likely to find minor problems. That includes common issues like weeping fittings, low fluid levels, and debris-filled components. If you can identify and repair these minor problems early, you can save yourself from a significant (and more expensive) repair down the road.

Safety Priority

Every company that uses forklift trucks has a legal and ethical responsibility to keep them in safe operating conditions. Because, of course, you want to make sure your team goes home at the end of every shift in one piece.

That is why regular forklift maintenance is essential. It helps identify general safety issues and repair them before they lead to a forklift operator or pedestrian being injured or possibly even killed.

Higher Resale Value

If you intend to trade in your forklift, a well-maintained vehicle will recoup a large portion of your initial investment in the secondary market. A well-maintained forklift commands a higher price than one in poor condition, which is quite evident.

Additionally, if you are leasing your tow motor, it is crucial to ensure regular maintenance. Otherwise, you will face a substantial bill when the lease ends.

OSHA’s Forklift Maintenance Requirements

Not only do these benefits provide reasons to set up – and keep to – a proper maintenance schedule, but OSHA (Occupational Safety and Health Administration) requires your lifts to be in tip-top shape before putting them into service.

Here are a couple of key standards from OSHA on the subject:

“Industrial trucks shall be examined before being placed in service, and shall not be placed in service if the examination shows any condition adversely affecting the safety of the vehicle. Such examination shall be made at least daily. Where industrial trucks are used on a round-the-clock basis, they shall be examined after each shift. Defects when found shall be immediately reported and corrected.”

– OSHA Standard 1910.178(q)(7)

“If at any time a powered industrial truck is found to be in need of repair, defective, or in any way unsafe, the truck shall be taken out of service until it has been restored to safe operating condition.”

– OSHA Standard 1910.178(p)(1)

These regulations are not to be taken lightly either. The penalties for disregarding OSHA-mandated forklift checks can be steep. In fact, companies have been fined huge sums of money for neglecting them:

- A meat company in Nebraska was fined $22,000 by OSHA in 2012 for forklift violations that should have been caught and corrected during a pre-trip inspection.

- A transportation company in Illinois was fined $108,020 by OSHA in 2014 for several safety violations, including failure to remove a forklift from an operation that needed repairs.

- A retail chain in Ohio was fined $258,672 by OSHA in 2018 for failure to fix faulty brakes despite being reported by their employees.

You might be wondering: Is there an OSHA daily forklift inspection checklist? The answer is that OSHA does provide a few generic inspection templates on its website.

However, OSHA does not specify the items to check because they vary depending on the truck type. Therefore, you are responsible for customizing the checklists to meet the specific requirements of the heavy-duty equipment you are operating.

We have made this simple by creating a free, downloadable pre-shift weekly inspection sheet that you can modify as needed. You will find it in the section below.

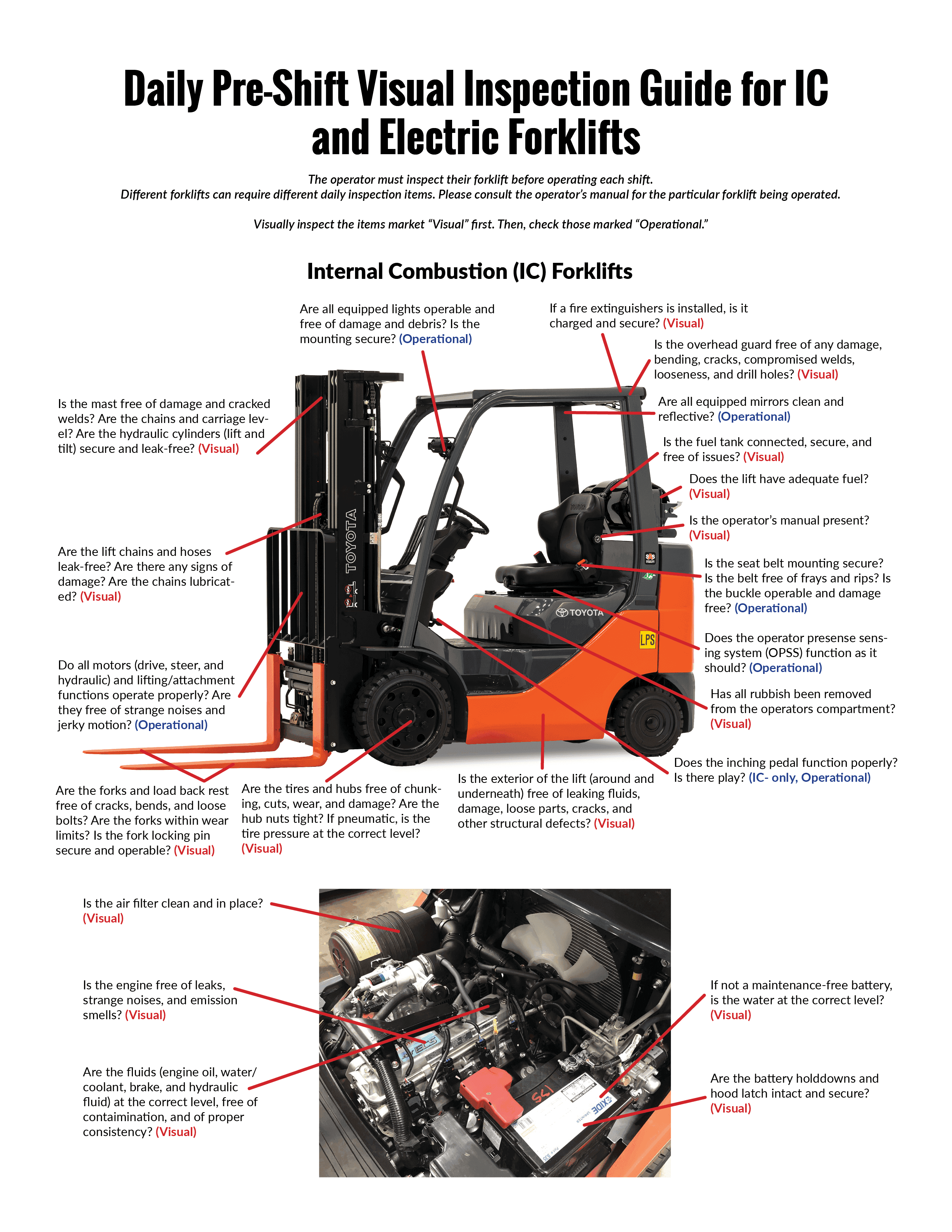

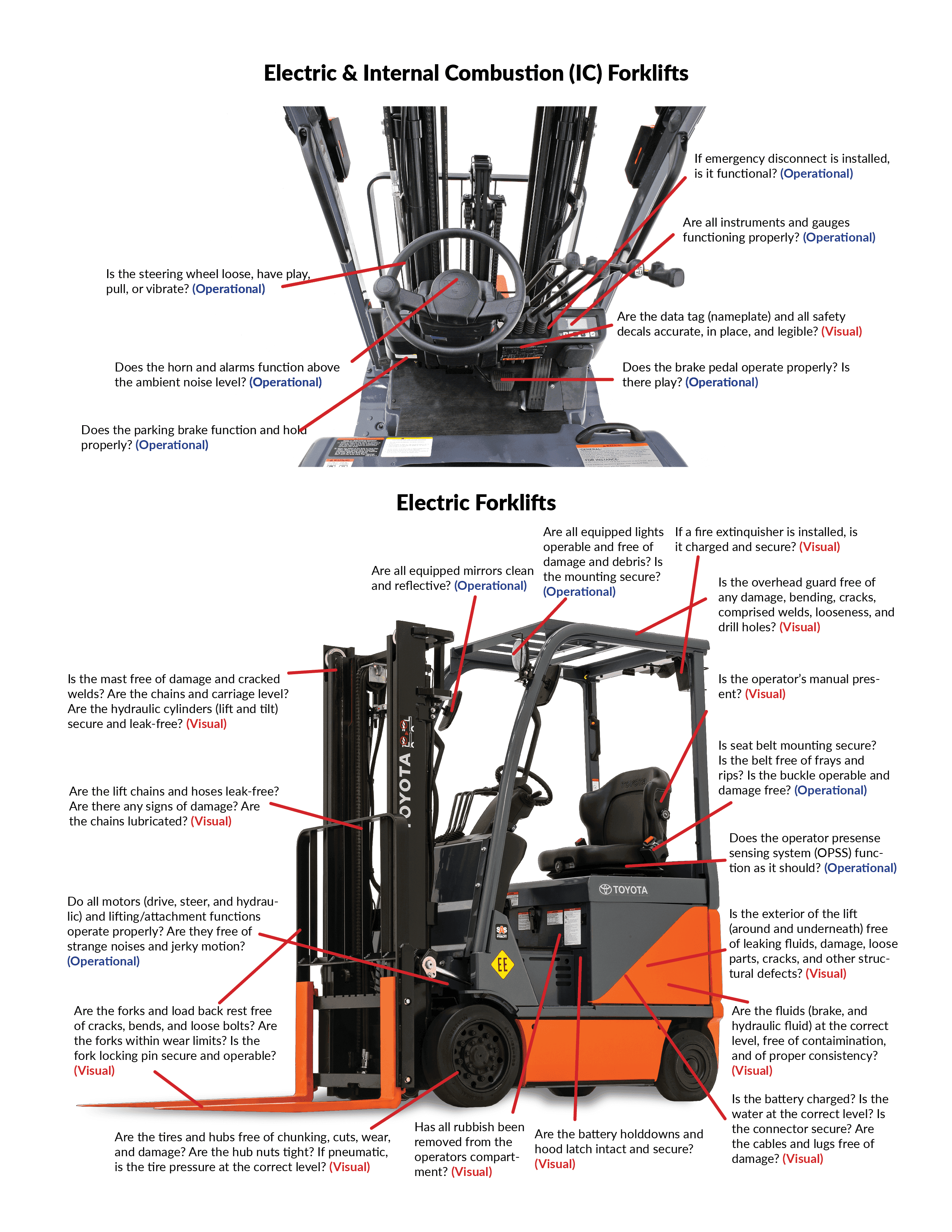

Daily Pre-Trip Inspection Items

We have taken the liberty to assemble the most common items that comprise a daily pre-trip inspection. And we have noted which items are for internal combustion (IC) and electric (E) trucks only.

Download Your Free Weekly Forklift Inspection Checklist

Print and reuse this free daily/weekly forklift inspection checklist template as often as required. Choose whichever format you would prefer below and click to download.

Download PDF Version Download Excel Version Download Visual Guide

That said, different forklifts can require different daily maintenance inspection items. So, consult the operator manual for the particular forklift you are operating.

How Often Should Forklifts Be Serviced?

Now that you know what items to check before operating, let us move on to the service actions required to maintain a forklift.

For starters, the two most common maintenance intervals for forklifts are:

-

Every six weeks or 250 hours

-

Every year or 2,000 hours

Both of these intervals have a different set of action items that must be inspected and serviced.

While these intervals are pretty standard, there are factors to consider when determining maintenance frequency. By keeping these in mind as you plan your service intervals, you will help to keep your heavy-duty machine in the best (and safest) operating condition.

Factors That Affect Maintenance Frequency

-

Manufacturer recommendations

Always adhere to the manufacturer’s recommended service intervals, which may differ depending on the manufacturer and the specific truck model. However, you can always find this information listed in the operator’s manual. (Remember: Every forklift is required to have a manual on it at all times!)

-

Fuel type

Internal combustion (IC) and electric forklifts require servicing at different intervals due to their distinct components.

Internal combustion trucks will need more frequent maintenance since they have more moving parts. But electric forklifts require less maintenance to be performed less often because they have fewer moving parts.

Operating environment

Trucks used in corrosive or abusive environments need more frequent maintenance. These operating environments include:

Service History

Does the forklift have a less-than-stellar history? Do service records show the same issue(s) appearing frequently? Do forklift operators regularly complain about it?

If the truck is a bad apple, it will need more frequent maintenance. You will want to keep an eye on its known problems and keep them at bay.

-

Hours of usage

If a forklift runs more often, it will require more frequent service. That is key for material handling operations that run their lifts multiple shifts.

Also, lift trucks with higher hours require more frequent maintenance.

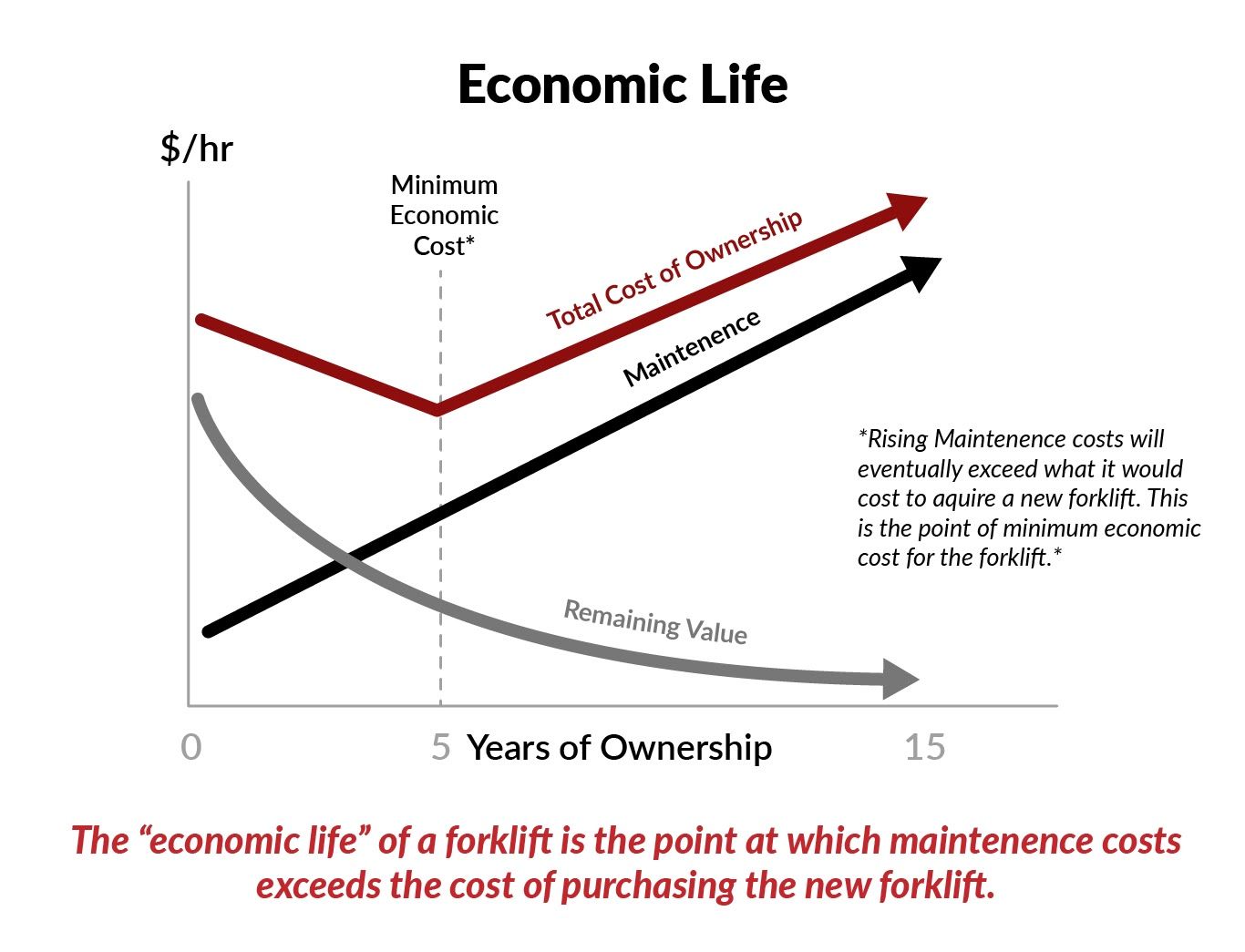

But be careful: There will come a point at which the lift becomes too expensive to continue repairing. That is called the “useful life“ of the forklift. And it means you are financially better off buying another one.

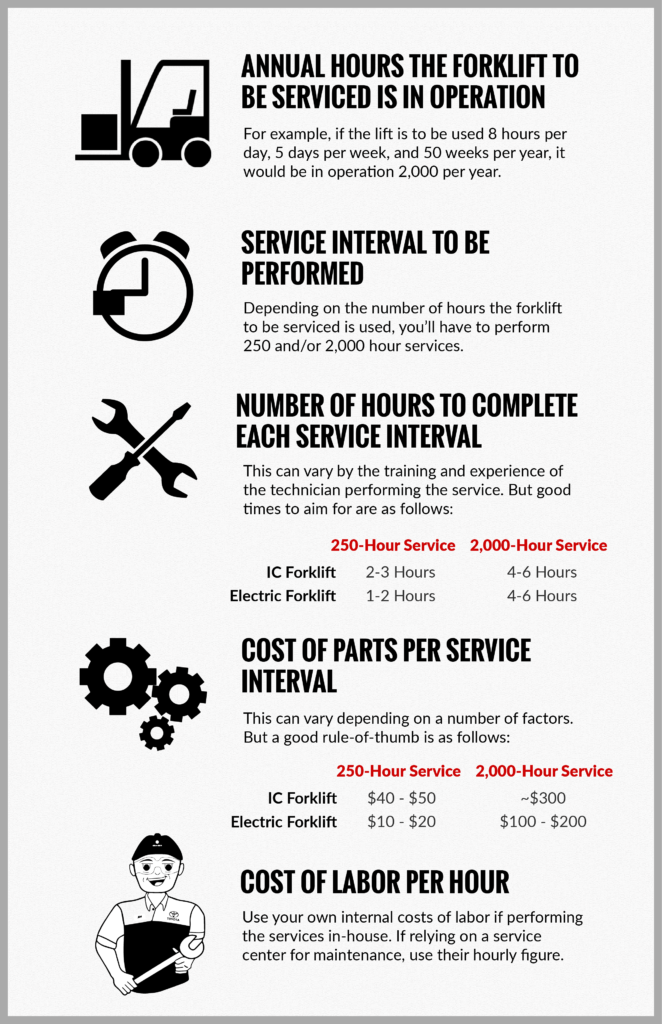

How Much Does it Cost to Maintain a Forklift?

As you now know, many factors influence how often you need to maintain your forklift. That also means the cost to maintain your forklift will vary. Plus, maintenance repair costs rise as lifts age. Your costs for the same lift will vary from year to year.

That said, a rule of thumb is that maintenance costs can range from $0.48 to $1.67 per operating hour and up from there.

How to Calculate Your Forklift Maintenance Costs

First off, you will need to know the following data:

Then, once you have got all your numbers, you can plug them into our free forklift maintenance calculator below for a rough cost estimate:

Download Our Free Forklift Maintenance Cost Calculator

Note: This file is in Excel format. You’ll be prompted to download and save it to your desktop. Then, simply enter the numbers you collected in the previous step to see your final estimated maintenance costs.

There are a lot of variables involved in accurately calculating your maintenance costs. For a more thorough and accurate estimate, refer to our partner company Unified Fleet Solutions (UFS).

When Maintenance Costs Too Much

There is an upper limit to how much you should pay for maintenance. It is called the “economic life” of your forklift. If you see the cost of maintenance inching towards $4 per hour, that is your cue to buy another forklift.

Forklift Maintenance Tips to Save Money

Now that you have a baseline figure for maintenance costs, here are some helpful and actionable forklift maintenance tips you can use to cut that figure down.

-

Perform Preventive Maintenance

It might sound counterintuitive, but the more maintenance you regularly perform, the lower your forklift repair bills will be. Regular preventive maintenance should help you catch little problems before they snowball into significant issues.

Wash Your Forklifts Regularly

If your forklift operates in a dirty environment, wash it with soap and water. Not only can dirt and debris cause several issues, including binding of the tires, mast damage, and electrical issues. OSHA requires your forklifts to be clean:

“Industrial trucks shall be kept in a clean condition, free of lint, excess oil, and grease. Noncombustible agents should be used for cleaning trucks. Low flash point (below 100 °F.) solvents shall not be used. High flash point (at or above 100 °F.) solvents may be used. Precautions regarding toxicity, ventilation, and fire hazard shall be consonant with the agent or solvent used.”

– OSHA Standard 1910.178(q)(10)

Pay special attention to the radiator in particular. Clogged radiators will cause the truck to overheat and lead to costly damage if allowed to persist. So include blowouts with air at least once per shift unless more often is required.

-

Retire Old Trucks

Remember that “economic life” stuff we just talked about? Well, get rid of old equipment when it reaches that breakpoint. Otherwise, you will start sinking into a money pit. Stick with newer equipment as much as possible to lower your maintenance costs.

-

Sign Up for Planned Maintenance

If you lack trained and certified forklift technicians or the staffing to maintain your forklifts regularly, consider enrolling in a forklift maintenance plan with a service center or dealership. Opt for a center with factory-trained forklift technicians by the manufacturer of your lifts. Such training equips them to diagnose and repair problems swiftly and efficiently, ultimately saving you money.

If you’re contracting your maintenance out, it usually comes in two different packages: Planned maintenance and full maintenance plans. With planned maintenance, usually, only the labor is covered. While full maintenance plans typically include forklift parts as well.

Looking for reliable forklift maintenance services in the Green Bay, Neenah, Wausau, Richfield or Madison areas? Look no further! Conger’s service centers are conveniently located in these regions, ready to provide top-notch support for your forklift maintenance needs.

The Most Common Forklift Maintenance Service Actions

We have broken down by component system the most common service actions. As in the daily inspection section, we have noted which items are for internal combustion (IC) or electric (E) trucks only.

Download the free checklists for each service interval for a more extensive list. You will find them in the next section below.

Power & Drive System

- Inspect for any fluid leaks.

- Change engine oil and filter (IC).

- Examine the starting condition and check for any strange noises (IC).

- Check the fuel system for leaks (IC).

- Inspect differential, torque converter, and transmission for oil level, leaks, looseness, and function (IC).

- Check clutch and inching pedal function (IC).

- Inspect fuel filter elements for clogs (IC).

- Clean the air filter (IC).

- Check radiator coolant level and for leaks (IC).

- Check coolant hoses for wear/damage (IC).

- Check fan belt tension for damage (IC).

- Inspect the exhaust system for operation, leaks, and damage (IC).

- Measure carbon monoxide concentration in exhaust gas (IC).

- Inspect the drive unit for oil leakage and level (E).

- Listen to the motor rotation sound (E).

- Check the motor and battery terminal for looseness (E).

- Check battery connector condition and connection (E).

- Check battery charging and electrolyte level (E).

- Inspect battery case for damage or wear (E).

- Measure the specific gravity of the battery (E).

Wheels, Axles, Steering & Brakes

- Check forklift tires for air pressure, damage, debris, and wear.

- Tighten hub nuts.

- Check the rim and side ring for damage.

- Inspect front and rear wheel bearings for noise and looseness.

- Check the rear axle beam for looseness.

- Inspect the steering wheel for functionality and play.

- Check power steering for oil leakage and mounting for looseness.

- Check kingpins for looseness.

- Check the brake fluid level.

- Test braking and park brake function, play, and operating force.

Forks, Attachment, Mast & Chains

- Check forks and stopper pins for wear/damage.

- Check the mast, mast rollers, mast strip, and lift bracket for cracked welds, looseness, and damage.

- Lubricate lifting chains.

- Check chain tension and look for damage.

- Inspect chain anchor bolt and chain wheel for condition.

- Check over attachments for damage, mounting security, and abnormal operation.

Hydraulic System

- Test overall hydraulic system operation.

- Replace the hydraulic oil return filter.

- Inspect the oil pump for leakage and unusual noises.

- Check the hydraulic tank oil level for signs of contamination or leaks.

- Check hydraulic cylinder mounting, cylinder rod, rod screw, and rod end for leaks, looseness, uneven lifting power, and damage.

- Inspect the control valve for leaks.

- Check hydraulic levers for looseness.

- Measure lifting speed and natural drop for all cylinders.

Electrical System

- Inspect distributor cap for cracking (IC).

- Check spark plug gaps and for signs of burning (IC).

- Check battery electrolyte level.

- Inspect the wiring harness for deterioration and damage.

- Inspect fuses for looseness and damage.

- Check the directional lever for operation and damage.

- Inspect contactors for contact, contamination, and damage (E).

- Inspect controller operation (E).

Forklift Safety Features

- Inspect overhead guard for cracked welds, damage, and deformation.

- Inspect the load backrest for damage, deformation, and looseness.

- Ensure lights, horns, indicators, backup alarms, and instruments operate and are mounted securely.

- Ensure operator presence sensing system (OPSS) operates.

- Check seat mounting for looseness and damage.

- Ensure the seat switch operates.

- Check seat belt mounting for looseness.

- Inspect seat belts for fraying and any damage.

- Clean mirrors.

Download Your Free Maintenance Checklists

We have developed a forklift maintenance checklist tailored to each service interval and designed for internal combustion (IC) and electric forklifts. Ensuring you will not overlook critical service checks, providing you peace of mind.

Plus, it will enable you to keep detailed records of all service actions taken for your fleet (essential for internal and external audits and in case OSHA comes knocking).

Heads Up…

These checklists are not meant to be exhaustive as they were adapted from Toyota’s internal combustion and electric pallet jack and forklift operator’s manuals.

Please consult the operator’s manual for your particular forklift before performing maintenance. You can edit the Excel files and add any extra items you find.

And remember: Only trained and authorized forklift technicians should perform service on forklifts of hand pallet jacks.

The operator should check each item above every day before operating the lift. If running multiple shifts, they should perform the inspection before each shift.

Propane Forklifts Maintenance Checklists

250-hour / 6-week Maintenance Checklist

Download PDF Version Download Excel Version

2,000-hour / 1-year Maintenance Checklist

Download PDF Version Download Excel Version

Electric Forklifts Maintenance Checklists

250-hour / 6-week Maintenance Checklist

Download PDF Version Download Excel Version

2,000-hour / 1-year Maintenance Checklist

Download PDF Version Download Excel Version

Wrapping It Up

There you have it. You now know what a forklift maintenance plan consists of, how frequently to perform it, and how much it costs. Plus, you’ve got some handy checklists to ensure you do not miss a step.